3M Welded Delivery Pipe for Zoomlion Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Welded Delivery Pipe for Zoomlion Concrete Pump

1. Structure of 3M Welded Delivery Pipe for Zoomlion Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of 3M Welded Delivery Pipe for Zoomlion Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

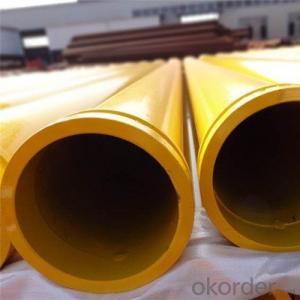

3. 3M Welded Delivery Pipe for Zoomlion Concrete Pump Images

4. 3M Welded Delivery Pipe for Zoomlion Concrete Pump Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: Can concrete pump spare parts be inspected or certified by third-party organizations?

- Yes, concrete pump spare parts can be inspected and certified by third-party organizations. These organizations have the expertise and knowledge to evaluate the quality, performance, and safety of the spare parts. By obtaining certification from these trustworthy third-party organizations, customers can have confidence in the reliability and durability of the concrete pump spare parts.

- Q: What are the signs of a malfunctioning hydraulic oil cooler?

- Some signs of a malfunctioning hydraulic oil cooler include overheating of the hydraulic system, decreased performance and efficiency of the equipment, increased hydraulic fluid leakage, abnormal noises or vibrations, and visible signs of coolant or oil leakage around the oil cooler.

- Q: Can concrete pump spare parts be customized for specific pump models?

- Yes, concrete pump spare parts can be customized for specific pump models. Concrete pumps come in various sizes and designs, and each model may have unique specifications and requirements for its spare parts. To ensure compatibility and optimal performance, it is important to customize the spare parts according to the specific pump model. This customization can include dimensions, materials, and other technical specifications that are tailored to fit the particular pump model. By customizing the spare parts, it ensures a perfect fit and enhances the efficiency and longevity of the concrete pump. Additionally, customization allows for potential improvements or modifications to the original design, resulting in enhanced performance and durability of the pump. Therefore, it is crucial to work with reputable manufacturers or suppliers who can provide customized concrete pump spare parts for specific pump models.

- Q: What are the specifications for concrete delivery pumps?

- In the cold season, the construction of concrete pump should have anti freeze measures

- Q: Can I get spare parts for both concrete pumps with and without boom stabilizers?

- Both concrete pumps with and without boom stabilizers have spare parts available. Concrete pump manufacturers typically offer a wide range of spare parts to ensure the longevity and smooth operation of their equipment. These spare parts may include hydraulic components, valves, hoses, seals, wear plates, pipes, and more. Whether your concrete pump has a boom stabilizer or not, you can easily find and purchase spare parts from the manufacturer or authorized dealers. Furthermore, there are aftermarket suppliers who specialize in providing spare parts for various concrete pump models. Therefore, regardless of the specific features of your concrete pump, you can be confident that spare parts are readily available to maintain the smooth functioning of your equipment.

- Q: What is the purpose of a concrete pump control panel?

- The purpose of a concrete pump control panel is to provide operators with a centralized interface to control various functions and parameters of the concrete pump. This control panel allows operators to start and stop the pump, control the speed and direction of the pump, and monitor and adjust the flow and pressure of the concrete being pumped. It also provides safety features such as emergency stop buttons and alarms to protect both the operators and the equipment. Additionally, the control panel may include diagnostic features that display real-time data and alerts for maintenance and troubleshooting purposes. Overall, the purpose of a concrete pump control panel is to enhance efficiency, accuracy, and safety in the operation of the concrete pumping process.

- Q: How do I properly maintain and replace rubber pistons in concrete pump spare parts?

- Proper maintenance and replacement of rubber pistons in concrete pump spare parts involves a few key steps. Firstly, make sure to regularly inspect the pistons for any signs of wear, such as cracks or tears. It is recommended to replace them if they are significantly worn or damaged. To replace the rubber pistons, start by removing the old piston carefully, ensuring not to damage the cylinder or any other components. Clean the cylinder thoroughly, removing any debris or residue. Apply a lubricant or concrete pump primer to the cylinder walls to aid in the installation of the new piston. Next, carefully install the new rubber piston, ensuring it is properly aligned with the cylinder. Gently push it into place, avoiding any unnecessary force that could cause damage. It is important to refer to the manufacturer's instructions or guidelines for specific installation techniques. After replacing the rubber piston, run a few tests to ensure its proper functioning. Check for proper sealing and smooth operation by conducting a dry run or pumping a small amount of concrete. Monitor the piston's performance closely, and if any issues arise, consult a professional or the manufacturer for further guidance. Regular maintenance, such as cleaning the cylinder and lubricating the pistons, can help extend their lifespan. Additionally, following proper operating procedures, such as avoiding excessive pressure or abrasive materials, can also contribute to the longevity of rubber pistons.

- Q: What is the purpose of a concrete pump cylinder?

- The purpose of a concrete pump cylinder is to provide the necessary pressure and force to push the concrete mixture through the pumping system and into the desired location, allowing for efficient and precise placement of concrete in construction projects.

- Q: What is the function of a concrete pump hydraulic accumulator?

- The function of a concrete pump hydraulic accumulator is to store energy from the hydraulic system and release it when needed, providing a surge of power to the concrete pump. This helps to maintain a consistent and smooth flow of concrete, preventing any disruptions or blockages in the pumping process.

- Q: What is the role of a concrete pump hopper agitator shaft?

- The role of a concrete pump hopper agitator shaft is to ensure the consistent and uniform mixing of concrete within the hopper. It rotates to prevent the concrete from settling or becoming compacted, ensuring a smooth and continuous flow of concrete through the pump, ultimately improving the efficiency and effectiveness of the pumping process.

Send your message to us

3M Welded Delivery Pipe for Zoomlion Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords