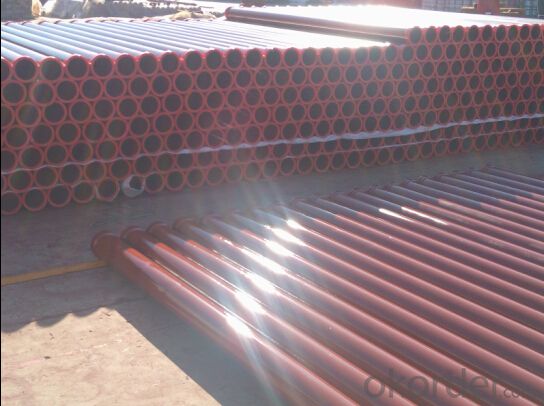

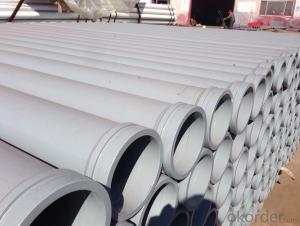

Concrete Pump Delivery Pipe 3 M*DN125*4.5Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Production Name: Delivery pipe 3 M*DN125*4.5Thickness

Materials: ST 52

Concrete Pumping Capacity: about20, 000M3

Inner Diameter: 125mm

Outer Diameter: 133mm

Thickness: 4.5mm

Length: 3000mm

Notes: total series of concrete delivery pipe for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc)available.

Scope of Application of the Equipment

Delivery pipe 3 M*DN125*4.5Thickness widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc. Our concrete delivery pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber piston, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

Product Advantages:

Delivery pipe 3 M*DN125*4.5Thickness are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have their ISO certifications, and adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Delivery pipe 3 M*DN125*4.5Thickness according to customers request?

A4: Yes, we can produce Delivery pipe 3 M*DN125*4.5Thickness according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: How often should a concrete pump cleaning ball be used?

- A concrete pump cleaning ball should be used after every use of the pump to ensure proper maintenance and prevent clogs or blockages.

- Q: How often should hopper cylinders be inspected or replaced in a concrete pump?

- Hopper cylinders in a concrete pump should be inspected regularly, ideally after every use, to ensure their proper functioning and prevent any potential issues. If any signs of wear, damage, or decreased performance are noticed, it is recommended to replace the hopper cylinders immediately to maintain the efficiency and safety of the concrete pump.

- Q: What is the role of a concrete pump agitator shaft seal?

- The role of a concrete pump agitator shaft seal is to prevent leakage of concrete slurry or other fluids from the agitator shaft, ensuring that the pump operates efficiently and without any loss or contamination of the material being pumped.

- Q: How often should concrete pump pistons be replaced?

- The frequency at which concrete pump pistons should be replaced depends on various factors such as the usage, maintenance, and the quality of the pistons. In general, it is recommended to inspect the pistons regularly for signs of wear and tear, including cracks, pitting, or scoring. If any of these signs are observed, it is advisable to replace the pistons immediately to prevent potential failures or leaks. Concrete pump pistons typically have a lifespan ranging from 25,000 to 75,000 cubic yards of concrete pumped, but this can vary based on the specific conditions and operating practices. For instance, if the concrete being pumped contains abrasive materials or if the pump is used intensively or under harsh conditions, the pistons may wear out more quickly. Additionally, proper maintenance practices can extend the lifespan of the pistons. This includes regular cleaning and lubrication, keeping the pump well-maintained, and ensuring that the pistons are properly aligned and not subjected to excessive pressure or stress. Ultimately, it is crucial to monitor the condition of the pistons closely and consult the manufacturer's recommendations or seek advice from a professional to determine the appropriate replacement interval for the specific concrete pump being used.

- Q: How often should concrete pump booms be inspected and maintained?

- Concrete pump booms should be inspected and maintained regularly, ideally on a monthly basis or as recommended by the manufacturer. This regular inspection and maintenance schedule helps ensure the safe and efficient operation of the equipment and minimize potential risks or breakdowns.

- Q: How can a damaged concrete pump piston affect the pumping efficiency?

- The pumping efficiency can be significantly affected in various ways by a piston that is damaged. To begin with, reduced pumping capacity can result from decreased power and force exerted by the pump due to a damaged piston. The piston's responsibility is to generate the necessary pressure for pushing the concrete mixture through the pumping system. If it is damaged, it may fail to generate adequate pressure, leading to slower and less efficient pumping. In addition, leaks can occur within the pump system due to a damaged piston. The piston plays a critical role in sealing the concrete and preventing it from leaking back into the hopper. If it is damaged or worn out, a tight seal may not be created, resulting in leakage. This not only leads to material loss but also reduces pumping efficiency as the pump has to compensate for the loss by working harder. Moreover, blockages and clogs can be caused by a damaged piston in the pumping system. The movement of the piston creates suction, which pulls the concrete mixture into the pump. If the piston is damaged, it may not create sufficient suction, causing the mixture to flow unevenly or get stuck in the system. This can cause delays and interruptions in the pumping process, ultimately reducing overall efficiency. In conclusion, the pumping efficiency can be negatively impacted by a damaged concrete pump piston through reduced power and force, leaks, and blockages. It is crucial to regularly maintain and promptly repair or replace damaged pistons to ensure optimal pumping performance and efficiency.

- Q: Which height of concrete pump is the most practical?

- The power of the concrete pump truck engine power is transmitted to the hydraulic pump or rear axle through the power transfer case, push the piston to drive the hydraulic pump concrete pump

- Q: How can a faulty battery affect the operation of the pump?

- A faulty battery can significantly affect the operation of a pump. Firstly, a faulty battery may not provide enough power to the pump, resulting in slow or weak pumping action. This can impact the pump's ability to generate the necessary pressure or flow rate, leading to inefficient or ineffective operation. Additionally, a faulty battery may cause intermittent power supply to the pump. This can result in inconsistent pumping action, with the pump starting and stopping sporadically. Such interruptions can create inefficiencies, reduce the pump's performance, and potentially cause damage to the equipment or system being operated. Furthermore, a faulty battery may not hold a charge for an extended period. This can limit the pump's runtime, requiring frequent recharging or replacement of the battery. In scenarios where a pump is needed for continuous or prolonged usage, a faulty battery can disrupt operations, leading to downtime and reduced productivity. Moreover, a faulty battery can also impact the overall lifespan of the pump. If the battery does not provide the necessary power consistently, the pump may experience strain or excessive wear, potentially shortening its operational life. Overall, a faulty battery can have various adverse effects on the operation of a pump, including reduced performance, inconsistent pumping action, limited runtime, potential damage, and decreased equipment lifespan. Regular maintenance and timely replacement of faulty batteries are crucial to ensure optimal pump performance and longevity.

- Q: How is the piping of the concrete pipe designed?

- When pumping underground structures, the horizontal axis of the ground shall be perpendicular to the axis of the Y - shaped discharge port

- Q: How can a malfunctioning control panel affect the pump's operation?

- A malfunctioning control panel can affect the pump's operation by causing errors in controlling the pump's speed, pressure, or flow rate. It can also lead to inaccurate monitoring of the pump's performance, failure to detect faults or abnormalities, and difficulty in troubleshooting issues. Ultimately, a malfunctioning control panel can compromise the pump's efficiency, reliability, and overall functionality.

Send your message to us

Concrete Pump Delivery Pipe 3 M*DN125*4.5Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches