Truck Mounted Concrete Pump Delivery Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Truck Mounted Concrete Pump Delivery Pipe

1. Structure of Truck Mounted Concrete Pump Delivery Pipe:

Include four types

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of Truck Mounted Concrete Pump Delivery Pipe:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

3. Truck Mounted Concrete Pump Delivery Pipe Images:

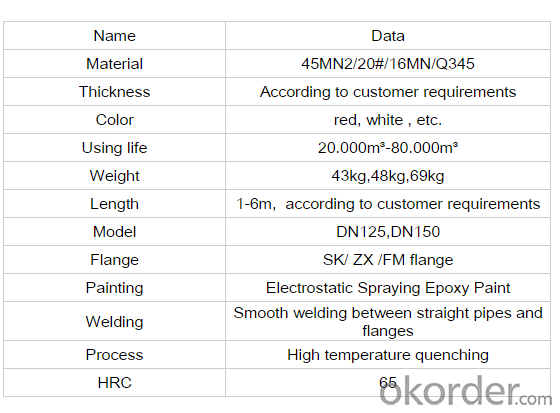

4. Truck Mounted Concrete Pump Delivery Pipe Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

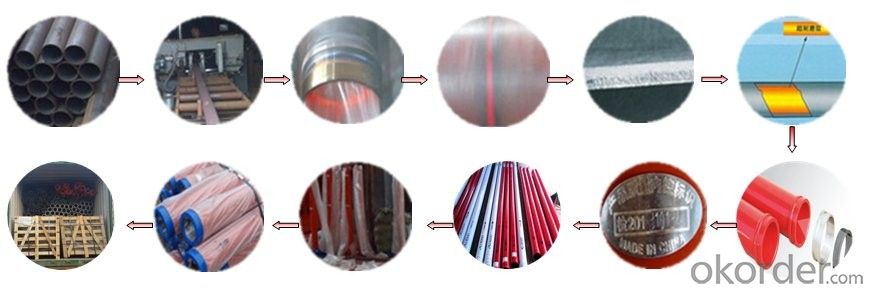

Production Process

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us:

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: Are there any specific guidelines for the installation of sensors or transmitters in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of sensors or transmitters in concrete pump spare parts. These guidelines are important to ensure the proper functioning and accurate readings of the sensors or transmitters. Firstly, it is crucial to carefully select the location for installing the sensors or transmitters. The chosen location should allow for easy access and maintenance, while also ensuring that the sensors or transmitters are not exposed to excessive vibration, moisture, or extreme temperatures. Secondly, it is recommended to use appropriate mounting hardware for securing the sensors or transmitters to the concrete pump spare parts. This hardware should be able to withstand the operating conditions and any potential vibrations or shocks that may occur during the pumping process. Additionally, it is important to follow the manufacturer's instructions for wiring and connection of the sensors or transmitters. Proper wiring and connection are essential to ensure accurate and reliable data transmission. Furthermore, regular inspections and maintenance should be conducted to ensure that the sensors or transmitters are functioning correctly. This includes checking for any loose connections, signs of wear or damage, and ensuring that the sensors or transmitters are calibrated properly. Overall, following these specific guidelines for the installation of sensors or transmitters in concrete pump spare parts can help to ensure their optimal performance and longevity, ultimately enhancing the efficiency and safety of the concrete pumping operation.

- Q: How can one ensure proper documentation and record-keeping for concrete pump spare parts?

- One can ensure proper documentation and record-keeping for concrete pump spare parts by implementing a structured system. This system should include keeping a detailed inventory of all spare parts, including their quantities, descriptions, and specifications. Additionally, it is essential to maintain a log of all incoming and outgoing spare parts, noting the date, purpose, and responsible personnel. Regular audits and reconciliations should be conducted to ensure accuracy and identify any discrepancies. Proper labeling and organization of physical storage areas, as well as digitizing records, can further enhance efficiency and accessibility. Regular training and clear guidelines for staff involved in handling spare parts documentation will also contribute to maintaining accurate records.

- Q: How often should a concrete pump spectacle plate be replaced?

- The frequency at which a concrete pump spectacle plate should be replaced largely depends on various factors such as the type of concrete being pumped, the intensity and duration of usage, and the overall maintenance and care given to the pump. However, as a general guideline, it is recommended to inspect and assess the condition of the spectacle plate regularly and replace it if any signs of wear, damage, or deformation are noticed. In some cases, this might be needed every few months, while in others it could be extended to a year or more. It is crucial to follow the manufacturer's recommendations and consult with industry professionals to determine the appropriate replacement schedule for the spectacle plate in order to maintain the optimal functioning and safety of the concrete pump.

- Q: How can I extend the lifespan of my concrete pump spare parts?

- To maximize the durability of your concrete pump spare parts, there are several essential measures you can take: 1. Maintenance should be a priority: Establish a comprehensive maintenance schedule for your concrete pump, which includes regular examinations, cleaning, and lubrication of the spare parts. By promptly identifying and addressing any issues, you can prevent further harm and prolong the lifespan of the parts. 2. Invest in top-quality spare parts: Consider purchasing high-quality spare parts from reputable manufacturers. While cheaper alternatives may save you money initially, they tend to wear out faster and require frequent replacements. Opting for quality parts guarantees their longevity and durability. 3. Proper storage is crucial: Store your spare parts in a clean, dry, and well-organized environment. Continuous exposure to moisture, extreme temperatures, and dirt can lead to deterioration over time. To shield the parts from dust and other contaminants, consider using protective covers or cases. 4. Train your operators effectively: Proper operation of the concrete pump is vital in preventing unnecessary wear and tear on the spare parts. Make sure your operators receive thorough training and adhere to the manufacturer's guidelines for usage and maintenance. Discourage any misuse or improper handling of the equipment, as this can result in premature wear of the spare parts. 5. Regularly clean your equipment: Ensure that your concrete pump remains clean by regularly removing any concrete buildup. The accumulation of hardened concrete can strain the spare parts and cause premature failure. Utilize appropriate cleaning methods and tools to ensure thorough removal without causing damage. 6. Promptly address repairs: As soon as you identify any issues or damage to the spare parts, address them promptly. Ignoring or delaying repairs can exacerbate the problem and potentially harm other components. Regularly inspect the spare parts for signs of wear, such as cracks, leaks, or excessive vibration, and promptly resolve any concerns. 7. Monitor usage and performance: Keep track of the usage and performance of your concrete pump and spare parts. Regularly assess the wear and tear of the parts and the overall performance of the pump. Analyze any patterns or trends that may indicate potential problems and take corrective actions to prevent further damage. By implementing these measures, you can significantly extend the lifespan of your concrete pump spare parts, ensuring optimal performance and reducing the need for frequent replacements.

- Q: Can I get spare parts for concrete pumps with different types of valve systems, such as S-valve or gate valve?

- Yes, it is possible to obtain spare parts for concrete pumps with different types of valve systems, including S-valve or gate valve. These spare parts are typically available through manufacturers, distributors, or specialized suppliers in the construction industry. It is important to identify the specific make and model of your concrete pump to ensure compatibility when purchasing spare parts.

- Q: Is the main pump of the concrete pump electric control or hydraulic control?

- Closed main oil pump behind the charge pump to provide a constant pressure to the displacement of the electromagnet by the current control output pressure to achieve the main pump pressure and pumping the commutation.

- Q: How can one identify the correct thread size and type for concrete pump spare parts?

- To identify the correct thread size and type for concrete pump spare parts, one can start by consulting the manufacturer's specifications and documentation. These resources often provide detailed information on the thread size and type used in the equipment. Additionally, measuring the existing thread on the spare part or the corresponding component can help determine the correct thread size and type. Utilizing thread gauges or consulting a professional in the industry can also provide accurate identification of the required thread size and type for concrete pump spare parts.

- Q: How long does it take to receive concrete pump spare parts after placing an order?

- The time it takes to receive concrete pump spare parts after placing an order can vary depending on various factors such as the availability of the parts, shipping methods, and the location of the supplier. However, it typically takes anywhere from a few days to a couple of weeks for the parts to be delivered. It is always advisable to check with the supplier or manufacturer for a more accurate estimate based on your specific order.

- Q: Are there any specific troubleshooting steps for identifying issues with concrete pump spare parts?

- Concrete pump spare parts can be identified for issues by following specific troubleshooting steps. These steps include conducting a thorough visual inspection of the spare parts to look for signs of wear, damage, or misalignment. Cracks, breaks, or any visible signs of damage should be checked for. The functionality of the spare parts can be tested by operating the concrete pump and paying attention to abnormal noises, vibrations, or irregular movements. A pressure test can be performed by connecting a pressure gauge to the pump and checking if it reaches the desired pressure levels. Any abnormal pressure fluctuations can indicate issues. A flow test can be conducted to evaluate the flow rate of the concrete through the pump and check for any blockages or irregular flow patterns. The spare parts should be inspected for leaks or fluid seepage, which can indicate faulty seals, gaskets, or fittings. Technical manuals provided by the manufacturer can be consulted for troubleshooting guidelines specific to the concrete pump spare parts. If unable to identify the issue, it is advisable to seek expert advice from a qualified technician or the manufacturer's technical support team. By following these troubleshooting steps, it becomes easier to promptly identify and address any issues with concrete pump spare parts.

- Q: How often should hydraulic cylinders be inspected or replaced in a concrete pump?

- Hydraulic cylinders in a concrete pump should be inspected regularly, ideally every 6 to 12 months, to ensure their proper functioning. Replacement of hydraulic cylinders should be done only when necessary, such as in cases of significant wear and tear, severe damage, or if they fail to meet safety standards.

Send your message to us

Truck Mounted Concrete Pump Delivery Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords