Concrete Delivery Pipe for Schwing Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Delivery Pipe for Schwing Concrete Pump

1. Structure of Concrete Delivery Pipe for Schwing Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of Concrete Delivery Pipe for Schwing Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

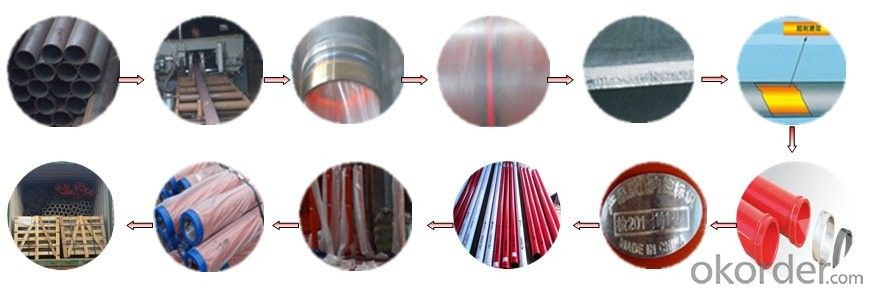

3. Concrete Delivery Pipe for Schwing Concrete Pump Images:

4. Concrete Delivery Pipe for Schwing Concrete Pump Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

Name | Data |

Material | 45MN2/20#/16MN/Q345 |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

Process | High temperature quenching |

HRC | 65 |

Production Process

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us:

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: Can concrete pump spare parts be pre-assembled or pre-tested before installation?

- Yes, concrete pump spare parts can be pre-assembled and pre-tested before installation. This practice ensures that the spare parts are functioning properly and ready for immediate use, saving time and effort during the installation process. Pre-assembly and pre-testing also help identify any potential issues or defects, allowing for necessary adjustments or replacements before installation, ensuring the smooth operation of the concrete pump.

- Q: Are there any specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts?

- Specific guidelines exist for the installation of hydraulic filters or strainers in concrete pump spare parts. These guidelines should be followed to ensure proper installation and functionality of the filter or strainer. Here are some important considerations: 1. Size and Compatibility: It is crucial to choose a hydraulic filter or strainer that is the correct size and compatible with the specific make and model of the concrete pump. Failure to do so can lead to inadequate filtration or damage to the hydraulic system. 2. Location: The filter or strainer should be installed in a location that allows for easy access and maintenance. It should be positioned in a way that facilitates proper filtration without obstructing the flow of hydraulic fluid. 3. Mounting: To prevent movement or vibration during operation, the filter or strainer must be securely mounted. It is essential to adhere to the manufacturer's instructions regarding proper mounting techniques and torque specifications. 4. Orientation: Pay attention to the recommended orientation of the filter or strainer. Some filters have specific flow direction requirements, and incorrect installation can impact their performance and efficiency. 5. Protection: Consider adding extra protection, such as a guard or shield, to shield the filter or strainer from external factors like debris or impacts. This can extend the lifespan and effectiveness of the filter. 6. Maintenance: Regularly inspecting and cleaning the filter or strainer is important to ensure optimal functioning. Adhere to the manufacturer's recommended maintenance schedule and procedures for replacement or cleaning to maintain efficient filtration. Remember to consult the manufacturer's instructions and guidelines for the specific hydraulic filter or strainer being installed, as they may have unique recommendations or requirements for their product.

- Q: Are there any specific maintenance practices for concrete pump spare parts?

- Yes, there are specific maintenance practices for concrete pump spare parts. Regular inspections, cleaning, and lubrication of the parts are essential to ensure their proper functioning and longevity. It is also important to follow manufacturer's guidelines and recommendations for maintenance and replacement of worn-out parts. Proper storage and handling of spare parts can also contribute to their durability and effectiveness.

- Q: What are the preventive measures for concrete pump?

- When installing and designing pipes, avoid 90 as much as possible. And S shaped bends.

- Q: How often should control system sensors be calibrated or replaced?

- The frequency at which control system sensors should be calibrated or replaced depends on several factors. These factors include the type of sensor, its application, environmental conditions, and the manufacturer's recommendations. In general, it is recommended to calibrate control system sensors at least once a year. However, certain sensors may require more frequent calibration due to their sensitivity or criticality in the system. For example, sensors used in safety-critical applications or those that are exposed to harsh environmental conditions may need to be calibrated more frequently, such as every six months or even quarterly. Additionally, it is important to monitor the performance of control system sensors regularly to ensure accurate readings and reliable operation. This can be achieved through routine maintenance and periodic checks. If any signs of sensor drift, inconsistency, or failure are observed during these checks, immediate calibration or replacement may be necessary. Moreover, the manufacturer's recommendations play a significant role in determining the calibration or replacement intervals. Each sensor has its own specifications and guidelines provided by the manufacturer. It is essential to follow these recommendations to maintain optimal performance and extend the lifespan of the sensor. Ultimately, the calibration or replacement frequency of control system sensors should be determined by a combination of factors including industry standards, application requirements, environmental conditions, and manufacturer's guidelines. Regular monitoring, routine maintenance, and adherence to these factors will ensure that control system sensors operate accurately and reliably.

- Q: How often should hopper grate pin retainers be inspected or replaced in a concrete pump?

- Hopper grate pin retainers in a concrete pump should be inspected regularly, ideally before each use, to ensure proper functioning and prevent any potential issues. If any signs of wear, damage, or looseness are detected, the retainers should be replaced immediately to maintain the efficiency and safety of the concrete pump operation.

- Q: What are the common challenges in sourcing spare parts for stationary concrete pumps?

- Sourcing spare parts for stationary concrete pumps can present various common obstacles. Firstly, availability poses a significant challenge. Depending on the concrete pump's brand and model, locating the exact spare parts needed can prove difficult. Some manufacturers lack a widespread distribution network, making it challenging to promptly locate the required spare parts. This difficulty is intensified if the concrete pump is an older model or if the manufacturer has ceased production. Another significant challenge is cost. Spare parts for stationary concrete pumps can be pricey, particularly when sourced directly from the manufacturer. Alongside the initial cost, additional expenses like shipping, customs duties, and taxes further escalate the overall cost of acquiring spare parts. Ensuring quality assurance is a crucial aspect when sourcing spare parts. It is vital to verify that the sourced spare parts are of high quality and compatible with the specific make and model of the concrete pump. Inferior spare parts can result in performance issues, breakdowns, and potential safety hazards, detrimentally impacting the overall efficiency and lifespan of the concrete pump. Timing also plays a pivotal role in spare parts sourcing. When a concrete pump malfunctions, it can cause delays in construction projects, leading to extra expenses and potential penalties. Therefore, swiftly and efficiently finding spare parts is essential to minimize downtime and ensure smooth operations. Additionally, language and communication barriers can present challenges. If the spare parts manufacturer or supplier is situated in a different country or speaks a different language, effective communication can be problematic. This can lead to misunderstandings, delays, and difficulties in accurately conveying specific spare parts requirements. To overcome these challenges, it is advisable to collaborate with reputable suppliers specializing in concrete pump spare parts. These suppliers often maintain a vast inventory of spare parts, ensuring availability and reducing the risk of delays. Furthermore, establishing strong relationships with local distributors or authorized service centers can streamline access to spare parts and technical support. Regular maintenance and proactive planning can also help mitigate the challenges of sourcing spare parts for stationary concrete pumps. Maintaining an inventory of essential spare parts and components can minimize downtime and ensure smooth operations.

- Q: Are there any warranties or guarantees available for concrete pump spare parts?

- Concrete pump spare parts come with warranties and guarantees to ensure their quality and performance. Various manufacturers and suppliers provide these warranties, which typically cover defects in materials or workmanship. The coverage period usually ranges from a few months to a year or more. Furthermore, some suppliers offer guarantees on the performance or durability of their spare parts, providing customers with reassurance. To ensure your protection in case of any issues, it is advisable to inquire about the specific warranty or guarantee terms before purchasing concrete pump spare parts.

- Q: What are the common issues that require replacement of concrete pump spare parts?

- There are several common issues that can arise in concrete pumps, leading to the need for replacement of spare parts. One common issue is wear and tear on the pump components. Over time, the constant movement of concrete through the pump can cause parts such as the piston, wear plate, and seals to deteriorate and require replacement. Another issue that can arise is blockages or clogs in the pump line. This can occur due to the buildup of hardened concrete or other debris, which can obstruct the flow of concrete. In such cases, it may be necessary to replace parts such as the delivery pipe or hose, or even the entire pump line, to ensure proper functioning. Leaks are another common problem that can occur in concrete pumps. These leaks can be caused by damaged or worn out seals, gaskets, or O-rings. If left unaddressed, leaks can lead to reduced pump performance and even potential safety hazards. Replacing the affected parts can help prevent further damage and ensure the pump operates efficiently. Additionally, pump malfunctions can occur due to electrical or mechanical issues. Faulty electrical components, such as switches or sensors, may need to be replaced to restore proper functionality. Mechanical problems, such as a worn-out gearbox or a malfunctioning hydraulic system, may also require replacement of specific pump parts. Overall, the common issues that require replacement of concrete pump spare parts include wear and tear, blockages, leaks, electrical malfunctions, and mechanical failures. Regular maintenance and inspection of the pump can help identify these issues early on, allowing for timely replacement of the necessary spare parts to keep the pump running smoothly.

- Q: What are the advantages of using ceramic components in concrete pump spare parts?

- There are several advantages of using ceramic components in concrete pump spare parts. Firstly, ceramic materials are known for their exceptional durability and wear resistance. Concrete pumps operate under high pressure and require components that can withstand the intense forces and abrasion. Ceramic parts have superior hardness and strength, making them highly resistant to wear and extending the lifespan of the spare parts. Secondly, ceramic components have excellent corrosion resistance. Concrete contains various chemicals and substances that can be corrosive to metals. By using ceramic parts, the risk of corrosion is significantly reduced, ensuring the longevity and reliability of the concrete pump spare parts. Additionally, ceramic materials have low friction coefficients. This means that when ceramic components are used in concrete pumps, there is less friction between the moving parts, resulting in reduced energy consumption and increased efficiency. This can lead to cost savings and improved overall performance of the concrete pump. Furthermore, ceramic parts have a high thermal resistance. Concrete pumps generate heat during operation, and this can cause damage or deformation to certain components. However, ceramic materials can withstand high temperatures without losing their structural integrity, ensuring the reliability and safety of the concrete pump. Lastly, ceramic components have excellent dimensional stability. They are less prone to expansion or contraction due to temperature changes, ensuring that the spare parts maintain their shape and fit accurately within the concrete pump. This precision fitting helps to minimize leakage and maintain the efficiency of the pump. In summary, the advantages of using ceramic components in concrete pump spare parts include exceptional durability, corrosion resistance, low friction, high thermal resistance, and dimensional stability. These benefits contribute to increased lifespan, improved performance, reduced maintenance costs, and enhanced overall efficiency of the concrete pump.

Send your message to us

Concrete Delivery Pipe for Schwing Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords