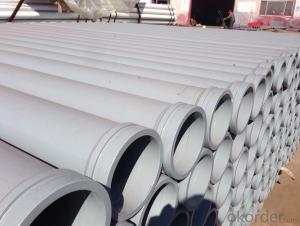

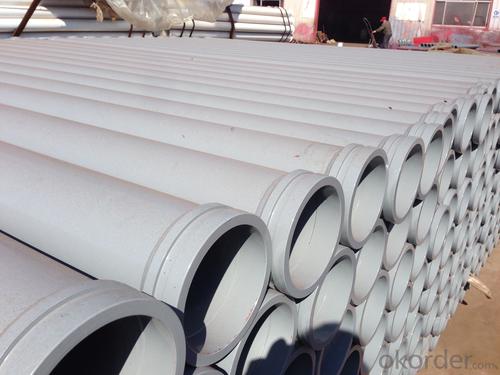

Concrete Pump Delivery Pipe 3 M*DN125*5.0 Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name: SCHWING Concrete Delivery Pipe

1. Specification of Concrete Delivery Pipe

Materials: High Manganese casting mn13-4

Concrete Pumping Capacity: about25, 000M3

Inner Diameter: 125mm

Outer Diameter: 133mm

Thickness: 5.0mm

Length: 3000mm

Notes: total series of concrete delivery pipe for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc)available.

2. Application of Concrete Delivery Pipe

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc.

Our concrete delivery pipes have been successfully exported to many countries from 1998, Our main markets as

below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we

can supply concretepump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber piston,

tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump

parts and accessory business.

3. Package and Delivery of Concrete Pump Elbow

Every 60pcs put in one seaworthy wooden box, and 20 boxes in one 20feet container.

Optional wood materials: veneer wood or other wood.

- Q: Are there any specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts. These guidelines ensure proper installation and optimal performance of the equipment. Here are some key guidelines to consider: 1. Inspection: Before installation, thoroughly inspect the wear plates or wear rings for any damage or defects. Any damaged or worn-out parts should be replaced to ensure efficient operation. 2. Cleanliness: Ensure that the concrete pump and all related components are clean and free from debris or contaminants. This will help prevent premature wear and extend the lifespan of the wear plates or wear rings. 3. Lubrication: Apply a suitable lubricant to the wear plates or wear rings before installation. This will help reduce friction and extend the service life of these components. 4. Alignment: Proper alignment is crucial for the effective functioning of wear plates or wear rings. Ensure that the plates or rings are aligned correctly and securely fixed in place. Misalignment can cause premature wear and damage to the equipment. 5. Tightening: Use the recommended torque specifications to tighten the bolts or fasteners that secure the wear plates or wear rings. Over-tightening or under-tightening can lead to improper functioning or damage to the equipment. 6. Regular Maintenance: Implement a regular maintenance schedule to inspect and replace worn-out wear plates or wear rings. Regular maintenance will help identify and address any issues before they lead to major breakdowns or costly repairs. It is important to consult the manufacturer's guidelines and follow their specific instructions for the installation of wear plates or wear rings in concrete pump spare parts. Adhering to these guidelines will ensure optimal performance and longevity of the equipment.

- Q: Are there any specific guidelines for the disposal of hydraulic fluids used in concrete pump spare parts?

- Concrete pump spare parts require specific guidelines for disposing of the hydraulic fluids they use. Hydraulic fluids contain chemicals and contaminants that can harm the environment if not disposed of correctly. Here are some general guidelines to follow: 1. Research local regulations: Different regions have specific laws and regulations for disposing of hydraulic fluids. It's important to familiarize yourself with these rules to make sure you comply. 2. Prevent leaks: Properly contain the hydraulic fluid to avoid leaks or spills during transportation. Use containers designed for hazardous materials. 3. Avoid mixing fluids: Don't mix hydraulic fluids with other substances as it can complicate disposal and increase environmental damage. 4. Find a licensed disposal facility: Locate a licensed facility that handles hazardous waste disposal. These facilities have the equipment and expertise to handle hydraulic fluids safely. 5. Follow instructions: When delivering the hydraulic fluid to the disposal facility, follow their specific drop-off instructions. They may require specific labeling or documentation for proper handling. 6. Consider recycling options: Depending on the type of hydraulic fluid, recycling might be an option. Some facilities specialize in recycling hydraulic fluids, which is more environmentally friendly. 7. Educate staff: Make sure all personnel working with hydraulic fluids understand proper disposal procedures and their importance. By following these guidelines, you can safely and responsibly dispose of hydraulic fluids used in concrete pump spare parts, minimizing environmental harm and complying with regulations.

- Q: Are there any specific tools required for replacing concrete pump spare parts?

- Yes, there are specific tools required for replacing concrete pump spare parts. Some of the common tools include wrenches, socket sets, screwdrivers, pliers, hammers, and pry bars. Additionally, specialized tools such as concrete pump piston pullers, gasket cutters, and sealant applicators may also be necessary depending on the specific parts being replaced. It is important to have the right tools to ensure safe and efficient replacement of concrete pump spare parts.

- Q: Can I get spare parts for both concrete pumps with and without pressure washers?

- Yes, you can get spare parts for both concrete pumps with and without pressure washers. Many manufacturers and suppliers offer a wide range of spare parts for concrete pumps, including those with pressure washers attached. These spare parts can include components such as hoses, nozzles, valves, cylinders, seals, filters, and other accessories needed for the proper functioning of the concrete pump. Whether you have a concrete pump with or without a pressure washer, it is important to ensure regular maintenance and timely replacement of worn-out or damaged parts to ensure optimal performance and longevity of the equipment.

- Q: How often should the concrete pump wear plate be replaced?

- The wear plate of a concrete pump needs to be replaced based on several factors such as the type and volume of concrete being pumped and the pump's operating conditions. Generally, wear plates are designed to endure a certain level of wear and tear before replacement is necessary. It is advisable to regularly inspect the wear plate to identify any signs of excessive wear, such as visible cracks, erosion, or a significant reduction in thickness. By conducting regular visual inspections, you can determine when it is time to replace the wear plate. Furthermore, monitoring the pump's performance and efficiency can offer insights into the wear and tear on the wear plate. If you notice a noticeable decrease in the pump's output or an increase in required pumping pressure, it may indicate that the wear plate needs replacement. However, it is vital to consult the manufacturer's guidelines and recommendations for your specific concrete pump model. These guidelines often provide information on the expected lifespan of the wear plate and the recommended replacement intervals. Following these guidelines will help ensure optimal performance and longevity of your concrete pump.

- Q: How often should hopper grate pin retainers be inspected or replaced in a concrete pump?

- To ensure proper functioning and prevent potential issues, it is important to regularly inspect hopper grate pin retainers in a concrete pump. Ideally, these inspections should be conducted on a monthly basis. However, the frequency of inspections may vary depending on usage conditions and manufacturer recommendations. During these inspections, it is essential to carefully examine the hopper grate pin retainers for any signs of wear, damage, or corrosion. If any of these issues are detected, immediate replacement is necessary to maintain the concrete pump's efficiency and safety. Furthermore, it is crucial to follow the manufacturer's guidelines regarding the lifespan of the hopper grate pin retainers. Some manufacturers may advise replacing them after a certain number of operating hours, while others may suggest replacement based on the condition observed during inspections. Regular inspections and timely replacement of hopper grate pin retainers play a crucial role in preventing malfunctions or accidents during concrete pumping operations. It is highly recommended to consult the concrete pump's manual or contact the manufacturer for specific guidelines on inspection and replacement intervals for hopper grate pin retainers.

- Q: What are some common issues with concrete pump pipes and how can they be prevented?

- Concrete pump pipes can experience several common issues, including blockages, leaks, and wear and tear. These problems can be avoided by implementing appropriate maintenance and operational practices. 1. Blockages: Concrete hardening inside the pipe can obstruct the flow, resulting in blockages. Regularly cleaning the pipes after each use is crucial to prevent blockages. Flushing the pipes with water or using a high-pressure air hose can eliminate any remaining material and prevent buildup. Furthermore, using concrete mixtures with the correct consistency and avoiding excessive use of additives can minimize the chances of blockages. 2. Leaks: Cracks or gaps in the pipe can cause concrete to leak out. Regularly inspecting the pipes is vital to detect any signs of damage or wear. Promptly repairing or replacing damaged sections can prevent leaks. It is also essential to use high-quality pipes that resist abrasion and chemical corrosion as they are less likely to develop leaks. 3. Wear and Tear: The operation of concrete pump pipes exposes them to significant stress and abrasion. This can eventually lead to wear and tear, resulting in weakened pipes or even breakages. To prevent excessive wear, it is important to utilize pipes made from durable materials like hardened steel or composite materials. Regularly inspecting the pipes for signs of wear, such as thinning or deformation, and replacing them as needed can help prevent sudden failures. 4. Pipe movement and alignment issues: During operation, concrete pump pipes may shift or become misaligned, which can decrease efficiency and potentially cause damage. To prevent this, ensure that the pipes are securely fastened to the pump and properly aligned. Using clamps and brackets or employing anti-vibration measures can help maintain the stability and alignment of the pipes during pumping operations. 5. Operator errors: Improper handling and operation can also contribute to problems with concrete pump pipes. Operators should receive adequate training in pump operation and pipe handling. Following recommended operating procedures, avoiding excessive pressure or flow rates, and exercising caution while maneuvering the pipes can prevent unnecessary strain and damage. In conclusion, proactive maintenance, proper handling, and the use of high-quality pipes can greatly reduce common issues with concrete pump pipes, ensuring smooth and efficient concrete pumping operations.

- Q: What are the potential risks associated with the installation and replacement of concrete pump spare parts?

- The potential risks associated with the installation and replacement of concrete pump spare parts include: 1. Safety hazards: Improper installation or replacement of spare parts can lead to accidents and injuries, as concrete pumps involve heavy machinery and high-pressure systems. Inadequate training or lack of knowledge can result in mishandling of equipment, leading to accidents for both the operators and nearby personnel. 2. Equipment damage: If the spare parts are not installed correctly, it can cause damage to the concrete pump or other components. This may result in costly repairs and downtime for the equipment, impacting productivity and project timelines. 3. Performance issues: Using incorrect or low-quality spare parts can affect the overall performance and efficiency of the concrete pump. It may result in reduced pumping capacity, increased wear and tear, and decreased reliability, compromising the quality of the concrete being pumped. 4. Warranty and liability concerns: Installing unauthorized or incompatible spare parts can void the manufacturer's warranty, leaving the responsibility for repairs and maintenance solely on the user. In case of any accidents or damages caused by faulty installation, the liability may fall on the individuals or companies responsible for the installation or replacement. To mitigate these risks, it is crucial to ensure proper training and certification for the personnel involved in the installation and replacement of concrete pump spare parts. Adhering to manufacturer guidelines, using genuine spare parts, and regularly inspecting and maintaining the equipment can also minimize potential risks and ensure safe and efficient operations.

- Q: How often should hydraulic cylinders be inspected or replaced in a concrete pump?

- Hydraulic cylinders in a concrete pump should be inspected regularly, ideally every 6 to 12 months, to ensure their proper functioning. Replacement of hydraulic cylinders should be done only when necessary, such as in cases of significant wear and tear, severe damage, or if they fail to meet safety standards.

- Q: What is the second generation pumping technology of concrete pump?

- The whole hydraulic control technology delivery pump has no constant pressure pump, no PLC in the control box, no nitrogen gas storage tank and no close switch at the water tank. The structure is simple, and the maintenance cost is greatly reduced.

Send your message to us

Concrete Pump Delivery Pipe 3 M*DN125*5.0 Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords