Concrete Pump Cleaning Ball DN125 with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

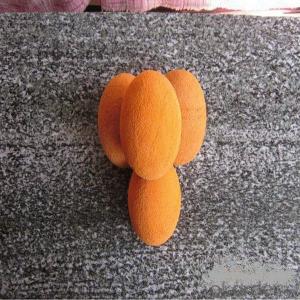

Product Name: Concrete Pump Cleaning Ball DN125 with Good Quality

1. Specification

Size | DN50 (2inch) OD: 60mm, soft/ hard/ medium soft |

DN80 (3inch) OD: 95mm, soft/ hard/ medium soft | |

DN100 (4inch) OD: 124mm, soft/ hard/ medium soft | |

DN125 (5inch) OD: 150mm, soft/ hard/ medium soft | |

DN150 (6inch) OD: 175mm, soft/ hard/ medium soft | |

Other specification is available according to your requirements. | |

Material | Natural rubber |

Application | Cleaning the pipeline of concrete pump and concrete pump truck in construction work equirement |

Serving brand of concrete pump | Sany, Zoomlion, Schwing, PM. CIFA etc |

2. Application

1.Applacation:cleaning the concrete pump pipeline

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Concrete Pump Cleaning Ball DN125 with Good Quality according to customers request?

A4: Yes, we can produce Concrete Pump Cleaning Ball DN125 with Good Quality according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image

- Q: What is the function of a concrete pump hopper grate pin?

- The purpose of a pin on a concrete pump hopper grate is to keep the grate securely in place and prevent it from moving or coming loose while concrete is being pumped. The pin acts as a locking mechanism, ensuring that the grate stays stable and does not pose any dangers or interrupt the pumping process. Furthermore, the pin allows for simple removal and replacement of the grate when needed, making it easier to maintain and clean the hopper. In conclusion, the concrete pump hopper grate pin is vital for preserving the reliability and effectiveness of the concrete pumping equipment.

- Q: What is the purpose of a concrete pump agitator motor?

- The purpose of a concrete pump agitator motor is to ensure the consistency and quality of the concrete mixture being pumped. It is responsible for keeping the concrete mixture well-mixed and preventing it from settling or separating during the pumping process. The agitator motor helps to maintain a uniform and homogenous mixture, which is crucial for achieving strong and durable concrete structures. By continuously agitating the concrete inside the pump, the motor helps to prevent any blockages or clogs that could potentially disrupt the pumping operation. Overall, the purpose of a concrete pump agitator motor is to enhance the efficiency and effectiveness of the concrete pumping process, ultimately resulting in better construction outcomes.

- Q: How do I identify the right spare part for my concrete pump model?

- To identify the right spare part for your concrete pump model, you should start by referring to the user manual or documentation provided by the manufacturer. This will usually include a detailed parts list and diagrams specific to your model. If you don't have access to the manual, you can contact the manufacturer or a reputable supplier for assistance. They will require information such as the pump model number, serial number, and specific details about the part you need. It's important to provide as much accurate information as possible to ensure you get the correct spare part for your concrete pump.

- Q: Are there any specific tools or equipment required for the installation of concrete pump spare parts?

- Concrete pump spare parts installation requires specific tools and equipment. The necessary tools include wrenches and sockets for bolt and nut tightening, hydraulic jacks for lifting heavy parts, and a crane or hoist for positioning extremely heavy components. To ensure secure installation, a torque wrench is used to tighten bolts to the correct torque specifications. Lubrication is achieved using a grease gun to apply grease to moving parts. Measuring tools like tapes or rulers are used for precise positioning and alignment. Safety goggles, gloves, and other protective gear should be worn during the installation process to prevent injuries. It is crucial to consult the manufacturer's instructions or seek professional assistance for proper installation, as the required tools and equipment may vary depending on the concrete pump's type and complexity.

- Q: How do I identify the specific spare parts I need for my concrete pump?

- To find the specific spare parts you require for your concrete pump, you can follow these guidelines: 1. Refer to the user manual: Begin by consulting the user manual provided by the manufacturer. This manual typically includes a comprehensive list of parts, along with their respective numbers and descriptions. It may also feature diagrams or illustrations to aid in identifying the necessary spare parts. 2. Get in touch with the manufacturer: Reach out to the manufacturer of your concrete pump. They possess the most accurate and up-to-date information regarding spare parts for your particular model. Provide them with the model number and any other relevant details to ensure precise identification of the required parts. 3. Connect with authorized dealers or distributors: If the manufacturer cannot directly provide you with the spare parts, they can often direct you to authorized dealers or distributors. These professionals specialize in concrete pump parts and can assist you in identifying the specific spare parts you need. Share the model number and any other pertinent details to aid them in locating the correct parts. 4. Capture images or dimensions: If you are unable to find the necessary information through the manual, manufacturer, or authorized dealers, you can take pictures or measurements of the damaged or worn-out parts. This will help visually identify the parts and provide accurate dimensions, which can be shared with suppliers or industry experts who may be able to offer further assistance. 5. Conduct online research: Utilize online resources such as parts catalogs, forums, or websites dedicated to concrete pump spare parts. These platforms often have extensive databases and knowledgeable communities that can help you identify the specific spare parts you require. Search for your concrete pump model and explore the available resources to find the relevant parts. Remember to prioritize quality and authenticity when purchasing spare parts for your concrete pump. It is crucial to buy from reputable sources to ensure the durability and longevity of your equipment.

- Q: How to calculate the power of concrete pump motor?

- First of all, the length of the pipe and pipe diameter and the motor power is basically nothing to do!

- Q: What are the signs of a damaged or malfunctioning electric motor?

- There are several signs that indicate a damaged or malfunctioning electric motor. Firstly, unusual noises such as grinding, squealing, or banging sounds are typically indicative of a problem. These sounds may suggest that the motor's bearings are worn out or that there is an issue with the motor's internal components. Secondly, excessive heat is another sign of a damaged electric motor. If the motor feels unusually hot to the touch, it could signify that the motor is working harder than it should be or that there is a problem with its cooling system. Thirdly, a motor that frequently trips the circuit breaker or blows fuses is a clear indication of a malfunction. This could be due to an electrical fault within the motor or an overload caused by a faulty component. Furthermore, a damaged electric motor may exhibit decreased performance or a noticeable decrease in power output. This could be observed as a decrease in speed or torque produced by the motor, or even a complete inability to start or function properly. Lastly, excessive vibration or shaking of the motor could indicate misalignment or an issue with the motor's mounting. This can lead to further damage if not addressed promptly. If any of these signs are observed, it is recommended to immediately stop using the motor and consult a qualified technician or electrician to diagnose and repair the problem. Ignoring or continuing to use a damaged motor can lead to further damage and potentially dangerous situations.

- Q: How often should hopper grate handles be inspected or replaced in a concrete pump?

- Regular inspections should be conducted on hopper grate handles in a concrete pump to identify any signs of wear and tear or damage. The frequency of these inspections and the need for replacement may vary depending on the equipment's usage and condition. It is suggested that the hopper grate handles be inspected at least once a month or after every 500 hours of operation, whichever occurs first. During the inspection, it is important to verify that the handles are firmly attached to the hopper grate and to examine them for any cracks, bends, or other structural problems. If any damage is detected, it is recommended to promptly replace the handles to prevent accidents or further harm to the equipment. It is also crucial to adhere to the manufacturer's guidelines and recommendations for the maintenance and replacement of hopper grate handles. By regularly inspecting and replacing the handles as necessary, the safe and efficient operation of the concrete pump can be ensured.

- Q: How do I properly maintain and replace wear plates in concrete pump spare parts?

- Properly maintaining and replacing wear plates in concrete pump spare parts is crucial for the optimal performance and longevity of your equipment. Here are the steps you can follow to ensure that the wear plates are properly maintained and replaced: 1. Regular inspection: It is important to regularly inspect the wear plates in your concrete pump spare parts to identify any signs of wear or damage. Look for cracks, excessive wear, or any other visible signs of deterioration. 2. Cleaning: Before replacing the wear plates, make sure to clean the area around them thoroughly. Remove any debris, dirt, or hardened concrete that might be present. Use a pressure washer or a wire brush to clean the surface properly. 3. Measure wear plate thickness: Measure the thickness of the wear plates using a precision measuring tool. Compare the current thickness with the manufacturer's recommended specifications to determine if replacement is necessary. If the wear plates are below the recommended thickness, it is time to replace them. 4. Remove old wear plates: Carefully remove the old wear plates using appropriate tools. Take note of their positions and any alignment marks to ensure correct installation of the new plates. 5. Prepare new wear plates: Before installing the new wear plates, ensure that they are of the correct size and specifications for your concrete pump. Check for any defects or damage in the new plates before proceeding. 6. Apply lubrication: Apply a thin layer of lubricant or anti-seize compound on the mating surface of the new wear plates. This will help prevent corrosion and ease future replacement. 7. Install the new wear plates: Position the new wear plates in the correct location, aligning them with any reference marks or indicators. Secure them tightly using the appropriate bolts or fasteners, making sure not to overtighten. 8. Test and check alignment: Once the new wear plates are installed, perform a test run of the concrete pump to ensure that everything is functioning properly. Check for any leaks, unusual vibrations, or misalignments. If any issues are detected, address them promptly. 9. Maintain regular maintenance schedule: To prevent premature wear and damage to the wear plates, establish a regular maintenance schedule. This may include cleaning, lubricating, and inspecting the wear plates at specified intervals or after a certain number of hours of operation. By following these steps and maintaining a proactive approach to wear plate maintenance and replacement, you can ensure the smooth operation and prolonged lifespan of your concrete pump spare parts.

- Q: How can a faulty lubrication system affect the pump's performance?

- A faulty lubrication system can negatively impact the pump's performance in several ways. Firstly, inadequate lubrication can increase friction and wear on the moving parts of the pump, leading to premature failure and reduced efficiency. Secondly, without proper lubrication, excessive heat can build up, causing parts to expand and potentially seize. This can further impair the pump's ability to move fluid effectively. Lastly, a faulty lubrication system may also introduce contaminants into the pump, which can damage components and disrupt the smooth operation of the pump. Overall, a malfunctioning lubrication system can significantly impair the performance and lifespan of the pump.

Send your message to us

Concrete Pump Cleaning Ball DN125 with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords