CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thickness nd148mm Flange

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

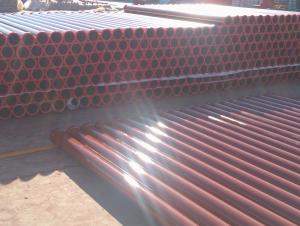

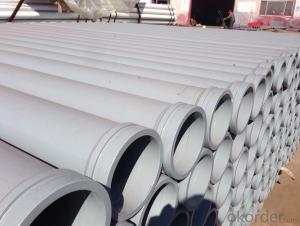

Production Name: CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thickness nd148mm Flange

Materials: ST 52

Concrete Pumping Capacity: about20, 000M3

Inner Diameter: 125mm

Outer Diameter: 133mm

Thickness: 4.5mm

Length: 3000mm

Notes: total series of concrete delivery pipe for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc)available.

Scope of Application of the Equipment

CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thickness widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc. Our concrete delivery pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber piston, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

Product Advantages:

CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thickness are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Product Specifications:

Dimensions and masses of the complete pipe and its major components

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have their ISO certifications, and adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thicknessaccording to customers request?

A4: Yes, we can produce CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thickness according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: What are the indications of a faulty control lever?

- There are several indications that can suggest a faulty control lever. First and foremost, if the control lever is not responding or is sluggish when you try to engage or disengage a specific function, it could be a sign of a problem. This could include difficulty shifting gears, adjusting speed, or operating various controls such as the throttle or clutch. Another indication of a faulty control lever is if it becomes loose or wobbly. If you notice excessive play or movement in the lever, it could indicate that the mechanism connecting the lever to the control system is worn out or damaged. This can compromise the accuracy and precision of the control lever, making it difficult to operate the intended functions effectively. Additionally, unusual noises or vibrations coming from the control lever can be a sign of a fault. This could be a result of loose or broken components within the control lever assembly, indicating that it needs to be inspected and repaired. Lastly, if the control lever becomes stuck or jammed in a certain position, it is a clear sign of a faulty lever. This can prevent you from properly controlling the equipment or vehicle, posing safety risks. In any case, if you suspect a faulty control lever, it is essential to have it inspected and repaired by a qualified technician to ensure proper functioning and safe operation.

- Q: What are the signs of a damaged concrete pump cylinder?

- There are several signs that can indicate a damaged concrete pump cylinder. One of the most obvious signs is leakage of hydraulic fluid from the cylinder. If you notice any fluid dripping or pooling around the cylinder, it could be an indication of a damaged seal or piston. Another sign of a damaged concrete pump cylinder is abnormal noise during operation. If you hear any unusual clanking, grinding, or knocking sounds coming from the pump, it could be a result of a damaged cylinder. This can be caused by a variety of issues such as a bent piston rod, worn out bearings, or misalignment of components. Decreased pumping efficiency is also a common sign of a damaged cylinder. If you notice that the pump is not delivering concrete as effectively as it used to, it could be due to a damaged cylinder. This can result in reduced output, slower pumping speed, or even complete failure to pump concrete. Visual inspection can also help identify signs of a damaged cylinder. Look for any visible cracks, dents, or deformations on the cylinder body. Additionally, check for any signs of excessive wear on the piston or piston rod, such as scratches or grooves. Lastly, if you experience frequent breakdowns or malfunctions with the concrete pump, it could be an indication of a damaged cylinder. Constant repairs or failures can be a result of underlying issues with the cylinder, such as fatigue, corrosion, or improper maintenance. If you notice any of these signs, it is important to address the issue promptly. Continuing to operate a concrete pump with a damaged cylinder can lead to further damage, increased repair costs, and potential safety hazards. It is recommended to consult a professional technician or manufacturer to assess and repair the damaged cylinder.

- Q: How can one determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts?

- Determining the appropriate viscosity and temperature range for lubricants used in concrete pump spare parts requires the consideration of multiple factors. Below are some steps that can assist in determining the suitable viscosity and temperature range: 1. Refer to the manufacturer's recommendations: To begin with, consult the specific guidelines or recommendations provided by the manufacturer for the concrete pump spare parts. The manufacturer may specify the required viscosity and temperature range for the lubricants used in their equipment. 2. Gain a clear understanding of the operating conditions: It is essential to have a comprehensive understanding of the operating conditions in which the concrete pump spare parts will be utilized. Factors such as ambient temperature, pump speed, load, and pressure should be taken into account. These factors can significantly impact the viscosity requirements and temperature range of the lubricant. 3. Assess the performance characteristics of the lubricant: Different lubricants possess distinct performance characteristics that make them suitable for particular applications. Look for lubricants specifically formulated for heavy-duty tasks, offering excellent wear protection and displaying good thermal stability. These performance characteristics ensure that the lubricant can endure the demanding conditions of a concrete pump. 4. Viscosity requirements: The viscosity of the lubricant plays a crucial role in ensuring proper lubrication and safeguarding of the concrete pump spare parts. Heavy-duty applications generally require higher viscosity lubricants, while lighter loads may be better suited with lower viscosity lubricants. The viscosity requirements may also differ depending on the specific pump parts, such as bearings, gears, or seals. Referring to the manufacturer's guidelines and seeking advice from lubricant suppliers can help determine the ideal viscosity range for the concrete pump spare parts. 5. Consider the temperature range: The temperature range within which the concrete pump operates is another significant aspect to consider. Lubricants should be capable of maintaining their viscosity and performance across the expected temperature range. Extreme temperatures can cause lubricants to lose their effectiveness, potentially leading to equipment damage or failure. Consequently, it is important to select lubricants with a temperature range suitable for the operating conditions of the concrete pump. 6. Consult with experts: If uncertainty persists regarding the appropriate viscosity and temperature range, it is advisable to seek advice from lubricant manufacturers, suppliers, or industry experts. They can offer valuable insights and recommendations based on their expertise and experience with concrete pump spare parts. By adhering to the manufacturer's recommendations, comprehending the operating conditions, evaluating the lubricant's performance characteristics, and seeking professional advice, it becomes possible to determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts. This will ensure optimal lubrication and extend the lifespan of the equipment.

- Q: What are the fittings of concrete pump?

- Fine stone concrete pump parts are: main oil cylinder, concrete cylinder, three-phase asynchronous motor, main oil pump, hopper, S pipe, electric distribution cabinet, hand oil pump, piston

- Q: How to calculate the power of concrete pump motor?

- Of course, the motor power is large, the transmission speed is fast

- Q: What is the importance of a good quality concrete pump seal?

- A good quality concrete pump seal is of utmost importance for several reasons. Firstly, it ensures the efficient and reliable functioning of the concrete pump. The seal is responsible for preventing any leakage or loss of pressure during the pumping process, which can lead to delays, inefficiencies, and potential damage to the pump itself. Moreover, a good quality seal helps maintain the integrity of the concrete being pumped. Concrete is a mixture of various materials, including water, cement, aggregates, and additives. To achieve the desired strength and durability, it is crucial that the concrete remains in its optimal state without any contamination or dilution. A high-quality seal prevents any external elements, such as water or air, from entering the pumping system and affecting the concrete's composition. Furthermore, a reliable seal contributes to the safety of the pumping operation. Concrete pumps are used in construction sites, where workers and equipment are present. Any failure or malfunction of the seal can lead to unexpected incidents, injuries, or damage to property. Therefore, a good quality seal provides peace of mind and reduces the risk of accidents. Lastly, investing in a good quality concrete pump seal can save both time and money in the long run. A durable and efficient seal minimizes the need for frequent replacements or repairs, reducing maintenance costs and downtime. It also ensures a smooth and continuous pumping process, allowing construction projects to be completed more efficiently and on schedule. In conclusion, a good quality concrete pump seal is crucial for the efficient functioning, integrity of the concrete, safety, and cost-effectiveness of a pumping operation. Therefore, it is essential to prioritize the selection and installation of a reliable seal to ensure the success and longevity of concrete pumping projects.

- Q: What is the purpose of a concrete pump accumulator?

- The concrete pump accumulator serves the purpose of storing energy and ensuring a continuous and uniform flow of concrete while pumping. It acts as a intermediary between the pump and the delivery line, guaranteeing a smooth and uninterrupted delivery of concrete. The accumulator functions by compressing air or nitrogen, which is then utilized to propel the concrete through the pipeline when the pump is not actively operating. This aids in maintaining pressure and preventing any obstructions or irregularities in the flow of concrete. Additionally, the accumulator can reduce the wear and tear on the pump by absorbing pressure fluctuations and providing a more controlled and consistent flow of concrete. In summary, the concrete pump accumulator aims to enhance the efficiency, reliability, and performance of the pumping process.

- Q: What are the precautions for gas washing of concrete pump?

- The valve must not be opened at once. It should be opened, closed, opened and carefully observed. It can only be opened when the concrete can flow smoothly

- Q: What is the role of a concrete pump hopper agitator shaft?

- To ensure consistent and uniform mixing of concrete in the hopper, the concrete pump hopper agitator shaft is responsible. It is equipped with paddles or blades that rotate within the hopper, effectively stirring the concrete and preventing it from settling or separating. This maintains the desired fluidity and consistency of the concrete, allowing for smooth and efficient pumping without any blockages. Additionally, the agitator shaft helps to remove any hardened or stuck concrete, ensuring that the hopper remains clean and obstruction-free. Ultimately, the agitator shaft plays a vital role in keeping the concrete well-mixed and ready for pumping, thereby improving the performance and productivity of the concrete pump.

- Q: Can concrete pump spare parts be recycled or disposed of responsibly?

- Yes, concrete pump spare parts can be recycled or disposed of responsibly. Many of the components used in concrete pump spare parts are made of materials such as steel, iron, and rubber, which can be recycled. These materials can be separated and sent to recycling facilities where they can be processed and reused in the manufacturing of new products. Additionally, responsible disposal methods can also be utilized for concrete pump spare parts that cannot be recycled. This includes ensuring that they are disposed of in designated waste management facilities, where they can be properly treated and managed. By recycling or disposing of concrete pump spare parts responsibly, we can minimize the environmental impact associated with their production and disposal. It is essential to follow proper recycling and waste management practices to ensure a sustainable approach towards the lifecycle of these spare parts.

Send your message to us

CONCRETE PUMP Delivery Pipe 3 M*DN125*4.5Thickness nd148mm Flange

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords