Biodegradable Complex Earthwork Compound Geotextile Membrane Cmax

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product description

Thickness1mm-3.0mm

Length50m/roll,100m/roll,150m/roll or as your choice

Width4m~9m or as your choice

ColorWhite/Black/Blue/Green,mainly black

MaterialHDPE

Package:woven bag or as customers' requests

Product time

2-20 days

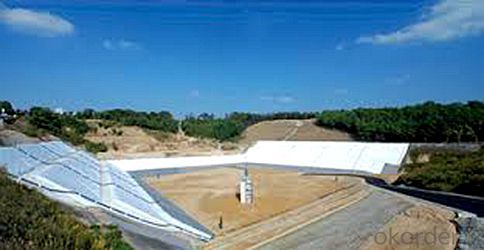

Geomembranes are the most widely used products for solid waste containment (such as landfill liners), mining, and water containment applications.

our factory uses the highest quality resins to manufacture the widest selection of high density polyethylene (HDPE) and linear low density polyethylene (LLDPE) geomembrane products available in either a black, green, white or Conductive upper surface, and in either a smooth or textured single or double-sided surface

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with vegetation establishment in landscaping projects?

- Geotextiles help with vegetation establishment in landscaping projects by providing a stable and supportive environment for plant growth. They act as a barrier, preventing erosion and soil movement, while allowing water and nutrients to pass through to the plants' root systems. Geotextiles also aid in weed suppression, creating a favorable condition for the establishment and growth of desired vegetation.

- Q: Can geotextiles be used for reinforcement of bridge abutments?

- Yes, geotextiles can be used for the reinforcement of bridge abutments. Geotextiles are commonly used in civil engineering applications for their ability to provide stability, filtration, and separation. When placed correctly, geotextiles can enhance the strength and durability of bridge abutments by distributing load, preventing soil erosion, and improving overall stability.

- Q: What are the factors to consider when designing geotextile-reinforced structures?

- When designing geotextile-reinforced structures, there are several factors that need to be considered. Firstly, the type and properties of the geotextile being used must be evaluated, including its strength, durability, and permeability. The soil conditions at the site, such as its composition, stability, and drainage characteristics, also play a significant role. The design should take into account the anticipated loads and stresses that the structure will be subjected to, as well as any potential environmental factors such as rainfall or seismic activity. Additionally, construction considerations, including the installation process, available equipment, and cost-effectiveness, should be taken into account. Overall, a comprehensive understanding of the site conditions, geotextile properties, and design requirements is crucial to ensure the successful and sustainable design of geotextile-reinforced structures.

- Q: Can geotextiles be used for reinforcement of landfills?

- Yes, geotextiles can be used for the reinforcement of landfills. Geotextiles are permeable fabrics that are used to improve the stability, drainage, and filtration of soil in various applications, including landfill construction. They are often employed to prevent soil erosion and provide support to the landfill structure, enhancing its overall stability and longevity.

- Q: What are the factors to consider when maintaining geotextiles?

- When maintaining geotextiles, there are several factors to consider. Firstly, it is important to regularly inspect the geotextiles for any signs of damage or wear. This includes checking for tears, holes, or fraying, as well as monitoring the overall condition of the material. Secondly, it is crucial to properly clean the geotextiles to prevent the buildup of dirt, debris, or organic matter that can compromise their effectiveness. This may involve using appropriate cleaning methods such as gentle washing or vacuuming. Additionally, considering the environmental and weather conditions in the specific location where the geotextiles are installed is essential. Extreme temperatures, UV exposure, and moisture levels can impact the durability and longevity of the material, so appropriate protective measures should be taken to mitigate these factors. Lastly, regular maintenance should include reassessing the performance of the geotextiles and their compatibility with the intended application. This may involve consulting with experts or conducting periodic testing to ensure that the geotextiles continue to meet the required standards and objectives. Overall, diligent inspection, cleaning, protection, and evaluation are key factors to consider when maintaining geotextiles.

- Q: Can geotextiles be used in flood protection projects?

- Yes, geotextiles can be used in flood protection projects. Geotextiles are often used as a component in flood control measures due to their ability to effectively filter and drain water while preventing soil erosion. They can be employed in various applications such as erosion control, slope stabilization, and shoreline protection, helping to mitigate the impact of floods and minimize damage to infrastructure and property.

- Q: Are geotextiles suitable for use in seismic zones?

- Yes, geotextiles are suitable for use in seismic zones. Geotextiles have been widely used in construction and civil engineering projects, including those located in seismic zones. They have proven to be effective in reinforcing soil, providing stability, and mitigating the impact of seismic events. Geotextiles can help improve the overall performance of structures by reducing soil liquefaction, enhancing soil drainage, and preventing soil erosion during seismic activities.

- Q: How do geotextiles help in reducing the risk of soil liquefaction?

- Geotextiles help in reducing the risk of soil liquefaction by providing reinforcement and stabilization to the soil. When geotextiles are installed in areas prone to liquefaction, they act as a barrier between the layers of soil, preventing the movement and flow of water. This restricts the buildup of excess pore water pressure within the soil, which is a major factor in causing soil liquefaction. Additionally, geotextiles improve the overall strength and cohesion of the soil, making it less susceptible to liquefaction under seismic or water-induced loading.

- Q: High-speed rail 2-type sliding layer to use two cloth a film, geotextile wool surface close to the concrete, but in the geotextile between the smooth and matte surface there is controversy, both sides of the geotextile is fluffy soft , A smooth side of some hard, hope to understand the master to answer the hairy side is smooth or matte surface? Thank you more

- You do not call geotextile cloth, you called the permeable template cloth, geotextile cloth on both sides of the hair!

- Q: Engineering geotextile non-woven fabrics where the cheapest can buy, where the wholesale market?

- Hello, I am a geotextile manufacturer, quality assurance geotextile, cost-effective, logistics benefits.

Send your message to us

Biodegradable Complex Earthwork Compound Geotextile Membrane Cmax

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords