Nilex Geotextile High Quality Geomembrane for Potable Water Cmax

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product description

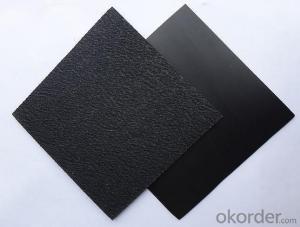

High-density polyethylene (HDPE), commonly used as a geomembrane and is similar to the material used in black polyethylene pipes. It has a broad chemical resistance and excellent UV resistance; all of them are with ISO certificates and widely accepted in USA, England, Russia, UAE, Mexico and other Asian countries.

Classified by Material

1. HDPE Geomembrane

2. LDPE Geomembrane

3. LLDPE Geomembrane

Function: Waterproof

Application:

Water conservancy projects

Landfill treatment projects

Mineral waterproofing

Agricultural waterproofing

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile lap joint with special equipment? How is the price

- Geotextile stitching is a professional equipment, professional equipment name for the portable sewing machine, the price is cheaper, generally ranging from 100-300 yuan. Look like this:

- Q: How do geotextiles contribute to erosion control on slopes?

- Geotextiles help in erosion control on slopes by providing a protective barrier that prevents soil erosion caused by water runoff. These synthetic fabrics are placed on the slope's surface or within the soil to stabilize it, reduce the velocity of water, and promote filtration. This helps to retain the soil in place, allowing vegetation to establish and roots to penetrate, thus reinforcing the slope and preventing erosion.

- Q: Do you want to make a geotextile?

- Is not the perforated tube, the cloth is not prevented from blocking the pipe hole. I am specializing in the production of geotextiles may be inside the trench inside the anti-seepage design, laying composite geomembrane

- Q: Are geotextiles suitable for use in geotextile tube dewatering systems?

- Yes, geotextiles are suitable for use in geotextile tube dewatering systems. Geotextiles are designed to provide filtration, separation, and reinforcement functions, making them ideal for use in dewatering systems that require the removal of water from sediments or sludge. The permeable nature of geotextiles allows water to pass through while retaining solids, ensuring efficient dewatering and sediment containment.

- Q: How do geotextiles help in the prevention of clogging in drainage systems?

- Geotextiles help prevent clogging in drainage systems by acting as a filter barrier, allowing water to pass through while trapping and preventing the migration of fine particles or soil into the drainage system. This helps maintain the long-term functionality and efficiency of the drainage system by reducing the risk of clogging or blockages.

- Q: What is the difference between woven and non-woven geotextiles?

- Woven geotextiles are made by interlacing yarns or fibers together in a regular pattern, creating a strong and durable fabric. Non-woven geotextiles, on the other hand, are manufactured by bonding or felting fibers together, forming a random web-like structure. This results in a fabric that is less strong but offers excellent filtration and drainage properties. In summary, woven geotextiles are stronger and more suitable for applications requiring high tensile strength, while non-woven geotextiles are ideal for filtration and drainage purposes.

- Q: How do geotextiles help with moisture management in construction projects?

- Geotextiles help with moisture management in construction projects by acting as a barrier that allows water to pass through while preventing soil erosion. They can be used to separate different layers of soil or aggregates, preventing the mixing of fine and coarse materials and ensuring proper drainage. Additionally, geotextiles can help control groundwater by providing filtration and reducing the risk of water accumulation, ultimately enhancing the overall stability and durability of construction projects.

- Q: What are the different methods of geotextile testing for strength and durability?

- There are several methods used to test the strength and durability of geotextiles. Some common methods include grab tensile strength testing, puncture resistance testing, tear resistance testing, burst strength testing, and UV resistance testing. Each method assesses specific properties of the geotextile to determine its strength and durability in various conditions and applications.

- Q: Unit of the quality of 400 geotextile piercing strong is generally how much? Hurry more

- First, geotextile polyester staple fiber geotextile (PET) and polyester filament geotextile two. Two kinds of geotextile anti-puncture strong (should be CBR burst strong) different. Polyester staple geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester staple geotextile CBR burst strength ≥ 2.1KN. Polyester filament geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester filament geotextile CBR burst strength ≥ 39KN. 400g GB polyester staple geotextile longitudinal and horizontal tear strength ≥ 0.33KN, 400g GB polyester filament geotextile longitudinal and horizontal tear strength ≥ 0.56KN.

- Q: Road overhaul of the original concrete pavement after shaving asphalt, anti-cracking is geotextile or geogrid more

- To see the specific situation, the general use of grille, I am specializing in the production of geotechnical materials

Send your message to us

Nilex Geotextile High Quality Geomembrane for Potable Water Cmax

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords