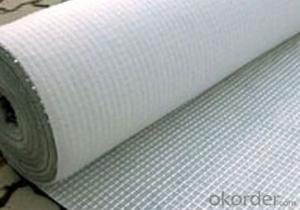

High Quality Spun-bond Geotextile fabric

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 20 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Spun-bond Geotextile fabric:

Good flexibility, permeability, filtration, separation and easy for construction.

Application of Spun-bond Geotextile fabric:

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway, highway, movement hall, Dams, hydraulic structures, hence hole, coastal shoal, reclamation, environmental protection and other projects. The main products are Synthetic staple fibers needle punched non woven geotextiles, we can produce with PET original and recylced material.

Specification of Spun-bond Geotextile fabric:

Item | Value | |||||||||

1 | Breaking strength | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

2 | Elongation at break | 40~80 | ||||||||

3 | CBR Mullen Burst Strength KN≥ | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

4 | Tear strength/KN | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 |

5 | Sieve Size O90mm | 0.05~0.20 | ||||||||

6 | Vertical Permeability Coefficient cm/s | K×(10ˉ1~10ˉ3),k=1.0~09.9 | ||||||||

7 | Thickness/mm | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

8 | Width Variation % | -0.5 | ||||||||

9 | Weight Variation % | -5 | ||||||||

- Q: Geotextile detection sampling, how many meters

- Two meters by two meters! Geotextile manufacturers to answer!

- Q: How do geotextiles help in preventing erosion around culverts?

- Geotextiles help in preventing erosion around culverts by providing a protective barrier against soil movement and water flow. They are placed around the culvert to stabilize the soil and prevent it from washing away during heavy rains or water flow. The geotextiles act as a filter, allowing water to pass through while effectively preventing soil particles from being carried away. This helps maintain the integrity and stability of the culvert structure, preventing erosion and ensuring long-term functionality.

- Q: Are high geotextiles harmful to people?

- High-tech geotextile is not harmful to people. High-iron geotextile for strong, tensile, anti-friction coefficient, anti-oxidation time and other indicators are very strict, it can be said that geotextile applications so far the highest requirements. The raw materials for the production of geotextile are polypropylene fiber, polypropylene fiber civilian use: can be pure or wool, cotton or viscose blended mixed woven to produce a variety of clothing. Can be used for weaving all kinds of knitwear such as socks, gloves, sweaters, knitted pants, dish cloth, mosquito cloth, was expo, warm filler, diaper wet. Industrial use: geotextile, industrial filter cloth, carpet, fishing nets, canvas, hose, concrete reinforced materials, industrial fabrics, nonwovens and so on. So do not worry, high-speed rail geotextile with environmental requirements, no harm to the human body.

- Q: What are the different geotextile durability test methods?

- There are various geotextile durability test methods including accelerated aging tests, puncture resistance tests, tensile strength tests, and exposure to environmental conditions such as UV radiation and chemical exposure. These tests help assess the long-term performance and durability of geotextiles in different applications.

- Q: Are geotextiles suitable for use in rain garden systems?

- Yes, geotextiles are suitable for use in rain garden systems. Geotextiles help to retain and filter water, prevent soil erosion, and provide stability to the rain garden system. They also allow water to infiltrate slowly, reducing runoff and promoting better water management in rain gardens.

- Q: Road Central isolation belt (5 m wide) Drainage No design Waterproof geotextile laying and gravel blind ditch, are design flaws?

- Should be it, the general design will have this. If you need to contact me, see the information

- Q: What are the different geotextile reinforcement techniques?

- Some of the different geotextile reinforcement techniques include mechanical stabilization, soil confinement, and erosion control. Mechanical stabilization involves using geotextiles to increase the strength and load-bearing capacity of soils, such as in road construction or retaining walls. Soil confinement refers to the use of geotextiles to prevent soil erosion and maintain the stability of slopes or embankments. Erosion control techniques involve using geotextiles to protect soil surfaces from the erosive forces of water or wind, helping to maintain the integrity of the landscape.

- Q: How do geotextiles improve the performance of shorelines?

- Geotextiles improve the performance of shorelines by providing erosion control, stabilizing the soil, and enhancing filtration. They act as a barrier against wave energy and currents, preventing the loss of sediment and minimizing erosion. Additionally, geotextiles help to reinforce and stabilize the shoreline, reducing the risk of land subsidence or collapse. Their permeable nature allows water to pass through while trapping sediment, reducing the accumulation of silt and pollutants. Overall, geotextiles play a crucial role in protecting and maintaining the integrity of shorelines.

- Q: How are geotextiles tested for durability?

- Geotextiles are typically tested for durability through a variety of methods such as tensile strength tests, puncture resistance tests, abrasion tests, and exposure to environmental conditions such as UV radiation and moisture. These tests assess the ability of geotextiles to withstand the stresses and strains they may encounter in their intended applications and ensure their long-term performance.

- Q: Geotextile drainage network and geotextile how to heat stick

- Geotextile and geotextile crimp part of the use of sewing or hot air welding. Hot air welding is the connection method of filament geotextile, that is, with the hot air gun on the connection of two pieces of cloth instantaneous high temperature heating, so that part of the molten state, and immediately use a certain external force to make it firmly together. In the case of wet (rain and snow) weather can not be hot adhesive connection, geotextile should take another method of a suture connection method, that is, with a dedicated sewing machine for two-wire suture connection, and the use of anti-chemical UV suture.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2006 |

| Annual Output Value | US$ 5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Spun-bond Geotextile fabric

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 20 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords