Geotextile Filtration Membrane Complex Earthwork Material Compound

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product description

HDPE waterproofing membranes use finest HDPE resin as raw material, they were made of inflation method and advanced automatic equipments, all the products are produced and inspected according to and complied with ASTM standard, CJ/T234 2006, GB/T17643 1998, etc.

They are complete in specifications: double smooth surface, double rough surface and single rough surface. The widest broad width can reach 8M, the thickness if 0.1 to 3.0mm.

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles effective in preventing soil contamination?

- Yes, geotextiles are effective in preventing soil contamination. They act as a barrier, preventing pollutants and contaminants from entering the soil. Geotextiles can filter out harmful substances, such as chemicals and heavy metals, while allowing water and air to pass through. They provide a protective layer that helps maintain soil quality and prevent contamination, making them a valuable tool in environmental protection and soil management.

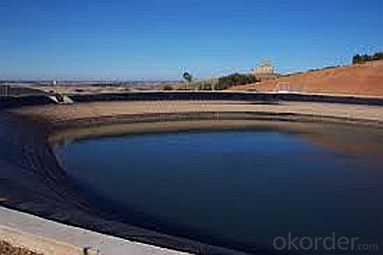

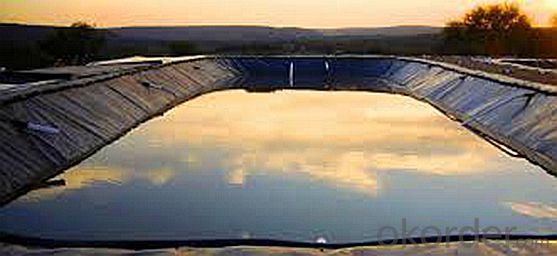

- Q: How do geotextiles help in the construction of ponds and lakes?

- Geotextiles help in the construction of ponds and lakes by providing reinforcement, filtration, and erosion control. They act as a barrier between the soil and water, preventing soil erosion and promoting stability. Geotextiles also help in filtering out any fine particles or contaminants, ensuring clean and clear water. Additionally, they enhance the strength and durability of the pond or lake structure, increasing its longevity and resistance to wear and tear.

- Q: Application Index of Geotextile Geotextile Expressway

- Too professional, and find a happy manufacturers it

- Q: How do geotextiles improve the performance of dams?

- Geotextiles improve the performance of dams by providing reinforcement, filtration, and separation functions. They enhance the stability of the dam structure by preventing soil erosion, reducing seepage, and increasing the overall durability. Additionally, geotextiles help in maintaining proper water flow, preventing the clogging of drainage systems, and enhancing the overall efficiency and longevity of the dam.

- Q: What are the factors to consider when designing geotextile-reinforced walls?

- When designing geotextile-reinforced walls, there are several factors that need to be considered. Firstly, the type and strength of the geotextile material must be chosen carefully to ensure it can effectively withstand the loads and stresses imposed by the wall's design and the soil conditions. Secondly, the wall's geometry and dimensions need to be determined, taking into account factors such as the height of the wall, the slope angle, and the overall stability requirements. Thirdly, the soil conditions and properties at the site should be thoroughly examined to understand their impact on the wall's design. This includes factors such as soil type, compaction level, moisture content, and shear strength. Additionally, the design should account for potential environmental factors such as rainfall, groundwater levels, and potential surcharges or seismic activity that could affect the stability of the wall. Furthermore, the construction and installation process needs to be considered, ensuring that the geotextile reinforcement is properly installed and securely connected to the wall structure. Overall, a comprehensive analysis of these factors is necessary to ensure the successful design and construction of geotextile-reinforced walls that are safe, durable, and effective in their intended purpose.

- Q: Geotextile 0.2 and 1.0 which is more sunscreen

- Hello, this friend, you ask the question should be wrong, geotextile should be geomembrane, geotextile specifications of the model is the weight and tension. Geomembrane is the thickness of the distinction, 0.2 refers to the 0,2 mm thick geomembrane, geomembrane by adding anti-ultraviolet raw materials, aquaculture aquatic organisms with 0.4mm geomembrane can be used for about 10 years, Henkel Building Materials Zang Cong for You answer, yes on the praise of a.

- Q: Can geotextiles be used in subgrade stabilization?

- Yes, geotextiles can be used in subgrade stabilization. Geotextiles are commonly used in civil engineering projects to improve the strength and stability of subgrade soils. They can help distribute loads, control soil erosion, and provide reinforcement to the subgrade, resulting in enhanced stability and increased bearing capacity.

- Q: What are the considerations for geotextile selection in riverbank stabilization?

- When selecting geotextiles for riverbank stabilization, several considerations should be taken into account. Firstly, the strength and durability of the geotextile are crucial factors. It should have sufficient tensile strength and resistance to degradation from UV radiation, chemicals, and biological agents. Additionally, the permeability of the geotextile plays a vital role in allowing water to pass through while preventing soil erosion. The geotextile should also be compatible with the soil type and vegetation in the area to ensure proper integration and long-term stability. Finally, the cost-effectiveness and ease of installation should be considered to ensure practicality and efficiency in the riverbank stabilization process.

- Q: How are geotextiles tested for strength and durability?

- Geotextiles are tested for strength and durability through various methods such as tensile testing, puncture resistance testing, tear resistance testing, and abrasion resistance testing. These tests involve subjecting the geotextiles to controlled forces, pressures, and wear to assess their ability to withstand different environmental conditions and loads.

- Q: Concrete maintenance with geotextile, Tonglu how to buy

- I specialize in producing geotextile materials

Send your message to us

Geotextile Filtration Membrane Complex Earthwork Material Compound

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords