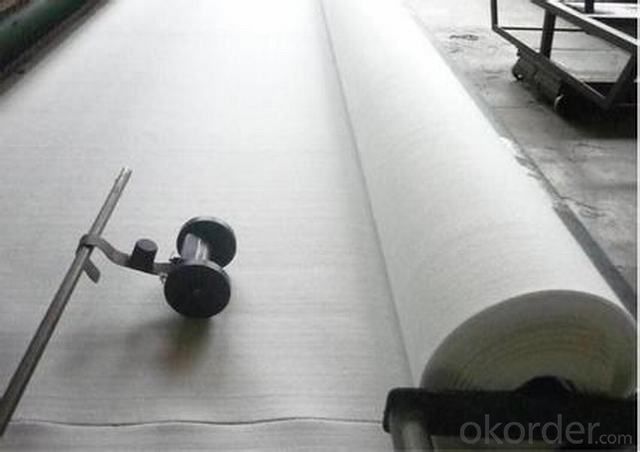

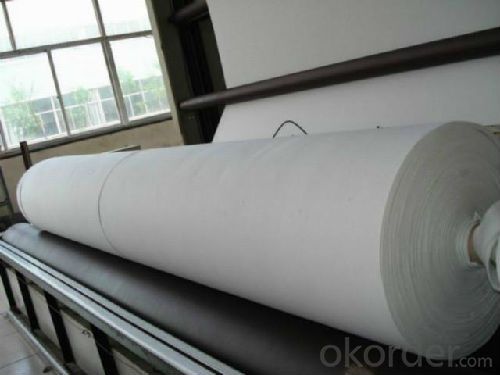

Geotextiles Tejidos - Non-Woven Geotextile Filament Spunbond Needle Punched Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(1) artificial filling foundation movement of ground water.

(2) gravel filter layer surrounding the periphery of the drain pipe drain.

(3) in water conservancy projects wells, relief wells or inclined pipe filter.

(4) for retaining wall backfill reinforcement, or for anchored retaining wall panel.

(5) reinforced flexible pavements, crack repair roads, prevent the reflection cracks of pavement.

(6) in ternal vertical or horizontal drainage, dissipation of pore water pressure in soil.

(7) water impermeable geomembrane dam or embankment in the lower part of the back or the concrete.

(8) the isolation layer between the road ballast and subgrade, isolation layer or between the embankment and soft foundation.

(9) the isolation layer soil between highway, airport, railway ballast and artificial rockfill and soil fabric.

FQA:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: What are the geotextiles for concrete health

- Geotextile waterproof material, can be used for artificial lake bottom waterproof

- Q: How do geotextiles aid in the reduction of settlement-induced cracking?

- Geotextiles aid in the reduction of settlement-induced cracking by providing a stable and reinforced base for construction projects. They distribute the load and enhance the soil's bearing capacity, preventing excessive settlement and subsequent cracking in the structure.

- Q: Can geotextiles be used in mine tailings dewatering applications?

- Yes, geotextiles can be used in mine tailings dewatering applications. Geotextiles provide filtration and separation functions, allowing for efficient dewatering of mine tailings by separating solids from liquids. They can help in reducing the moisture content of the tailings, making them easier to handle and manage. Geotextiles also aid in improving the stability and strength of the dewatered tailings, minimizing the risk of slope failures or environmental contamination.

- Q: Geotextile price in the end is how much?

- Geotextile raw materials are also different prices, geotextile prices with the market changes, geotextile prices from one yuan to twenty yuan variable. After-sales service and thoughtful, customer satisfaction as the goal. Hongxiang geotechnical

- Q: Can geotextiles be used in the construction of green roofs?

- Yes, geotextiles can be used in the construction of green roofs. Geotextiles are often used as a protective layer to separate the growing medium from the underlying roof structure, providing drainage and preventing soil erosion. They also help in retaining moisture and promoting healthy plant growth on green roofs.

- Q: Can geotextiles be used in landscaping?

- Yes, geotextiles can be used in landscaping. They are commonly used to control erosion, separate different soil layers, and provide stability to slopes or retaining walls. Additionally, geotextiles can be used as a weed barrier, allowing water to pass through while preventing weed growth in landscaped areas.

- Q: Are geotextiles cost-effective?

- Yes, geotextiles are generally considered cost-effective due to their durability, longevity, and ability to prevent soil erosion and improve stability in various construction projects. They can reduce the need for expensive excavation or drainage systems, saving both time and money. Additionally, geotextiles can enhance the performance and lifespan of infrastructure, reducing maintenance and replacement costs in the long run.

- Q: Can geotextiles be used for erosion control in golf courses?

- Yes, geotextiles can be used for erosion control in golf courses. Geotextiles are permeable fabrics that can be installed to stabilize soil and prevent erosion by providing a barrier against water flow. They are commonly used in various landscaping applications, including golf course construction and maintenance, to control erosion and improve soil stability.

- Q: what is the life span of a geotextile tube ?

- Engineered geotextiles have design lives of up to 120yrs. It depends on what geotextile you are talking about and what environment it is placed in.

- Q: Geotextile puncture test standard

- Staple stitch filament piercing filament woven weaving

1. Manufacturer Overview

| Location | Taian City,Shandong Province,China |

| Year Established | 2003 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, North America, Eastern Europe, South Asia, Western Europe |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid;Geocell;Geonet and Geomat;Plastic Safety Fence);Plastics products;Rubber products;Geotextile;Carpet;Compound geomembrane |

| Product Price Range | Average |

Send your message to us

Geotextiles Tejidos - Non-Woven Geotextile Filament Spunbond Needle Punched Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords