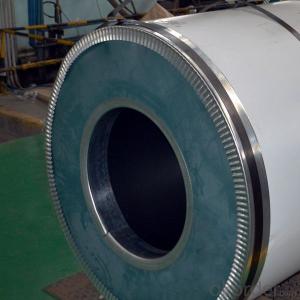

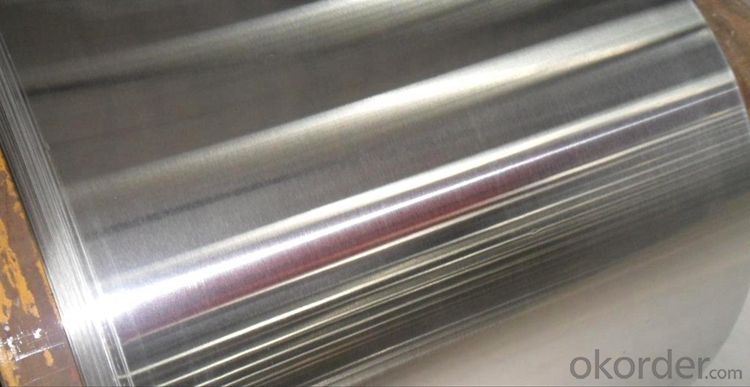

Cold Rolled Steel Coils 2B Finish Grade 304 Grade 316 Grade 430

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: How do you prevent discoloration on stainless steel sheets?

- To prevent discoloration on stainless steel sheets, there are several measures you can take. 1. Regular Cleaning: Proper and regular cleaning is essential to prevent discoloration on stainless steel sheets. Use mild soap or detergent and warm water to clean the surface. Avoid using abrasive cleaners or scrubbing pads as they can cause scratches that may lead to discoloration. 2. Avoid Harsh Chemicals: Avoid using harsh chemicals or cleaners containing chlorine, bleach, ammonia, or acids as they can cause pitting or corrosion on the stainless steel surface, leading to discoloration. Stick to mild and non-abrasive cleaners specifically designed for stainless steel. 3. Rinse Thoroughly: After cleaning, make sure to rinse the stainless steel sheet thoroughly with clean water to remove any residue from the cleaning solution. Residual chemicals can cause discoloration if left on the surface for an extended period. 4. Dry Completely: After cleaning and rinsing, it is important to dry the stainless steel sheet completely. Moisture left on the surface can lead to water spots or staining, especially in environments with hard water. Use a soft cloth or towel to remove all moisture, ensuring a dry and shiny surface. 5. Protective Coatings: Applying protective coatings or sealants designed for stainless steel can help prevent discoloration. These coatings create a barrier that protects the surface from environmental factors, such as humidity, oxidation, and staining. 6. Proper Handling and Care: Avoid dragging or sliding objects across stainless steel sheets, as this can cause scratches or abrasions that may lead to discoloration. Handle the sheets with care, using clean gloves or a soft, non-abrasive cloth to minimize the risk of surface damage. 7. Regular Maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration or damage. Promptly address any issues by following the appropriate cleaning and maintenance procedures to prevent further damage and maintain the appearance of the stainless steel. By following these preventive measures, you can effectively minimize discoloration on stainless steel sheets and keep them looking clean, shiny, and stain-free for a longer period.

- Q: Can stainless steel sheets be used for column covers?

- Yes, stainless steel sheets can be used for column covers. Stainless steel is a durable and corrosion-resistant material, making it suitable for exterior applications. It provides an attractive and modern finish that can enhance the aesthetic appeal of a building. Stainless steel sheets can be easily fabricated and installed to fit around columns, creating a sleek and seamless appearance. Additionally, stainless steel is low maintenance and easy to clean, making it a practical choice for column covers that are exposed to the elements.

- Q: What type of stainless steel plate made by imported vibrating disk?

- The company has a professional design, development, production, customer service and other functions, can you demand, we provide solutions at the same time, and to achieve rapid delivery, to ensure product quality on the basis of our commitment: each vibration plate from manufacturing to the factory, all in strict accordance with the company's quality assurance system, quality and to complete the process standard, allow customers ease of use

- Q: What is the maximum temperature stainless steel sheets can withstand?

- The maximum temperature that stainless steel sheets can typically withstand is around 1500-1650°F (815-900°C). However, it is important to note that this temperature limit can vary depending on the specific grade and composition of the stainless steel.

- Q: Are stainless steel sheets suitable for chemical processing plants?

- Chemical processing plants find stainless steel sheets highly suitable. The reason lies in the excellent corrosion resistance that stainless steel offers, making it the ideal choice for environments with chemicals. It can resist a wide range of chemicals, including acids, alkalis, and solvents, which are commonly present in chemical processing plants. Moreover, stainless steel sheets provide high strength and durability, enabling them to endure harsh operating conditions and maintain their structural integrity over time. They are also easy to clean and maintain, ensuring a hygienic environment in chemical processing plants. Furthermore, stainless steel sheets possess favorable thermal properties, making them appropriate for applications involving extreme temperatures. Additionally, they have low magnetic permeability, which proves advantageous in certain chemical processing operations. All in all, stainless steel sheets are a favored option in chemical processing plants due to their corrosion resistance, strength, durability, and ease of maintenance.

- Q: Are stainless steel sheets resistant to lactic acid?

- Stainless steel sheets are commonly resistant to lactic acid. The corrosion resistance of stainless steel is well-known, and lactic acid is generally not potent enough to cause substantial harm to surfaces made of stainless steel. Nevertheless, the level of resistance may differ based on the specific grade and quality of stainless steel employed. To ensure the suitability of stainless steel sheets for applications involving lactic acid, it is advisable to seek guidance from a material expert or conduct appropriate testing.

- Q: Are stainless steel sheets suitable for hygienic applications?

- Yes, stainless steel sheets are highly suitable for hygienic applications. Stainless steel is corrosion-resistant, non-porous, and easy to clean, making it ideal for environments that require strict hygiene standards, such as hospitals, food processing plants, and laboratories. Additionally, stainless steel has antimicrobial properties that inhibit the growth of bacteria, further enhancing its suitability for hygienic applications.

- Q: What is the price range for stainless steel sheets?

- The cost of stainless steel sheets can fluctuate based on several factors, including the thickness, size, and grade of the stainless steel. Typically, thinner sheets begin around $30 per square foot, while thicker or higher-grade sheets can reach up to $150 per square foot. It is crucial to consider that market conditions and supplier pricing policies may also impact prices. Thus, it is advisable to compare prices from various suppliers before finalizing a purchase.

- Q: What is the electrical conductivity of stainless steel sheets?

- The electrical conductivity of stainless steel sheets can vary depending on the specific grade and composition of the stainless steel. Generally, stainless steel is not known for its high electrical conductivity compared to other metals such as copper or aluminum. However, it still possesses some level of electrical conductivity. The electrical conductivity of stainless steel is typically lower than that of most metals because it contains a higher proportion of non-conductive elements such as chromium and nickel. Stainless steel is often chosen for its corrosion resistance rather than its electrical conductivity. However, it can still be used in certain electrical applications where moderate conductivity is acceptable.

- Q: How do I determine the flatness of stainless steel sheets?

- To assess the flatness of stainless steel sheets, the following steps can be followed: 1. Visual Examination: Initially, visually inspect the sheet for any visible indications of warping, bending, or unevenness. Look for noticeable waves, ripples, or twists on the surface. While this method may not provide precise results, it can give a preliminary understanding of the overall flatness of the sheet. 2. Straight Edge Measurement: Position a straight edge, such as a ruler or long level, on the surface of the stainless steel sheet. Move the straight edge across different areas of the sheet, paying attention to both the center and edges. Observe if there are any gaps or spaces between the straight edge and the sheet. A continuous contact between the straight edge and the sheet suggests a satisfactory level of flatness. 3. Feeler Gauge Utilization: Employ a feeler gauge, which is a precise measurement tool containing thin metal blades of varying thicknesses. This tool can be used to more accurately measure the gap between the straight edge and the stainless steel sheet. Slide the feeler gauge into any gaps between the sheet and the straight edge, noting the blade thickness that fits snugly. This will help determine the extent of any unevenness or bowing present. 4. Laser Measurement: For more accurate measurements, a laser measuring device can be employed. Position the laser device at one end of the sheet and measure the distance from the laser to the surface at different points along the length of the sheet. Repeat this process at the opposite end of the sheet. Comparing these measurements will provide an indication of any variations in flatness. 5. Professional Testing: In cases where the stainless steel sheets are intended for critical applications or when precise flatness is essential, consulting with a professional testing service is advisable. These experts can employ advanced techniques such as optical profilometry or coordinate measuring machines to accurately measure the flatness of the sheet. It is important to acknowledge that due to the inherent characteristics of stainless steel, minor deviations from perfect flatness may be acceptable within industry standards. The required level of flatness will depend on the specific application and the tolerance standards set by the manufacturer or customer.

Send your message to us

Cold Rolled Steel Coils 2B Finish Grade 304 Grade 316 Grade 430

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords