Cold Rolled Steel Coils Grade 304L NO.2B Finish with High Quality China best Seller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

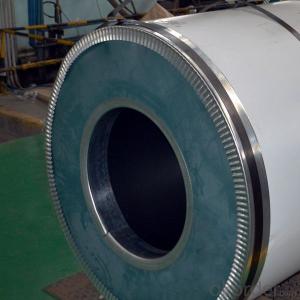

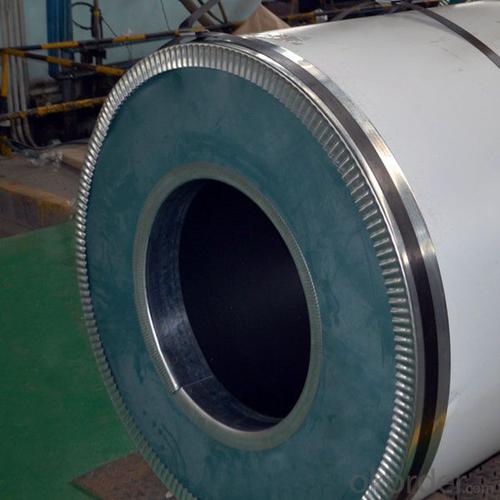

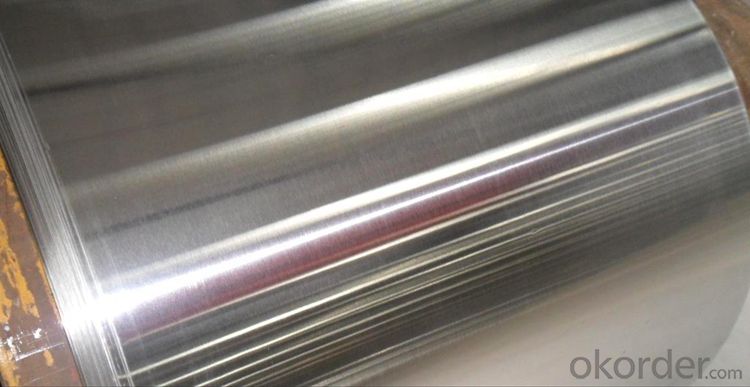

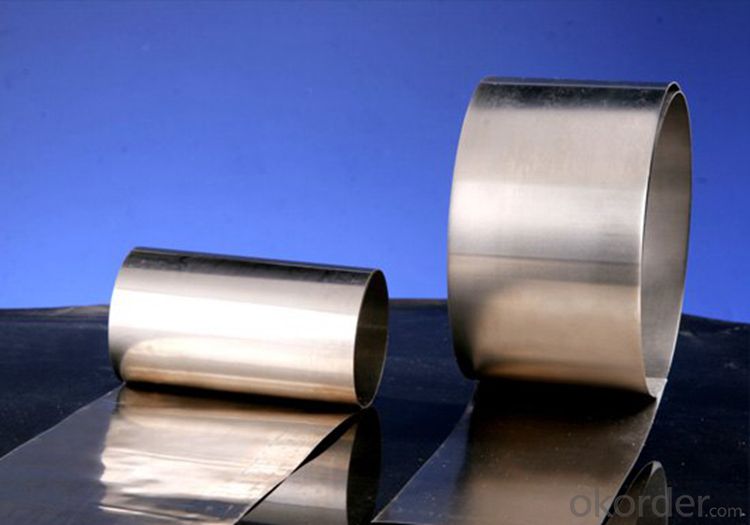

Cold Rolled Steel Coils Grade 304L NO.2B Finish

with High Quality China best Seller

Products Description

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Application

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Q: How long is the delivery time?

FAQ

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for automotive applications?

- Yes, stainless steel sheets can be and are commonly used for various automotive applications. This is due to their excellent corrosion resistance, durability, and aesthetic appeal, making them suitable for components such as exhaust systems, body panels, trim, and interior parts in automobiles.

- Q: Are stainless steel sheets suitable for cleanroom applications?

- Indeed, stainless steel sheets prove to be apt for cleanroom applications. The reason lies in the fact that stainless steel boasts exceptional resistance against corrosion, a trait that holds immense importance in cleanroom environments where the utmost cleanliness and hygiene are paramount. Furthermore, stainless steel exhibits remarkable durability and effortless cleanability, rendering it an ideal choice for maintaining cleanliness standards in cleanrooms. Moreover, stainless steel possesses a non-porous nature, thereby preventing the absorption of contaminants and facilitating easy sanitization. Its resistance to chemicals further adds to its suitability for cleanroom applications that involve the use of potent disinfectants or cleaning agents. All in all, stainless steel sheets provide a dependable and hygienic surface for cleanroom applications.

- Q: Are stainless steel sheets suitable for elevator control panels?

- Yes, stainless steel sheets are suitable for elevator control panels. Stainless steel is a durable and resistant material that can withstand various environmental conditions, including frequent use and exposure to moisture, heat, and chemicals. Elevator control panels often require a material that is easy to clean, resistant to scratches and dents, and aesthetically pleasing. Stainless steel meets all these criteria, making it an ideal choice for elevator control panels. Additionally, stainless steel has a sleek and modern appearance, which can enhance the overall design of the elevator interior.

- Q: What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets depend on various factors such as the thickness, grade, and temper of the material. However, generally speaking, stainless steel sheets can be bent to a certain degree without causing permanent deformation or cracking. It is important to consult specific bending charts or guidelines provided by manufacturers to determine the precise bending limits for a particular stainless steel sheet.

- Q: Can stainless steel sheets be used in the medical industry?

- Yes, stainless steel sheets can be used in the medical industry. Stainless steel is highly resistant to corrosion and is known for its durability and strength. It is commonly used in medical equipment, surgical instruments, implants, and even in the construction of medical facilities. Its non-reactive and easy-to-clean properties make it suitable for medical applications, ensuring the safety and hygiene of patients.

- Q: What glue does the board and the stainless steel stick to?

- Board and stainless steel fast drying, you can choose one adhesive HY-303 glue to bonding, quick curing, simple and convenient operation. Slow dry, you can choose HY-106AB glue to bonding, high temperature resistance, good weather resistance.

- Q: What are the different types of colored finishes available for stainless steel sheets?

- Stainless steel sheets come in a variety of colored finishes that serve to enhance their appearance and offer different aesthetic options. Some of the most popular colored finishes include: 1. Mirror Finish: This particular finish achieves a highly reflective, mirror-like surface on the stainless steel sheets. By polishing the stainless steel surface to a high gloss, a sleek and modern look is achieved. Mirror finishes are commonly used for decorative purposes. 2. Satin Finish: Also known as a brushed or matte finish, this type of finish provides a smooth, non-reflective surface. It is achieved by brushing the stainless steel surface with an abrasive material. Satin finishes are commonly used in architectural and industrial applications, giving off a clean and contemporary appearance. 3. Colored Powder Coating: This finish involves applying a dry powder to the stainless steel surface and then curing it under heat. The result is a durable and uniform colored finish. Colored powder coatings offer a wide range of hues, allowing for customization and versatility in design. 4. PVD Coating: The process of Physical Vapor Deposition (PVD) entails depositing a thin layer of metal onto the stainless steel surface. This coating can be in various colors, such as gold, bronze, black, or rose gold. PVD coatings are highly durable and resistant to wear, making them suitable for high-traffic areas or decorative applications. 5. Colored Anodizing: This finish is achieved through an electrochemical process that creates a protective oxide layer on the stainless steel surface. By incorporating dyes into the anodizing process, a plethora of colors can be achieved. Colored anodized finishes are known for their corrosion resistance and find utility in architectural or design-oriented applications. Each of these colored finishes possesses unique characteristics and can be selected based on desired aesthetics, durability, and specific application requirements. It is crucial to consider factors such as maintenance requirements, environmental conditions, and intended use when choosing a colored finish for stainless steel sheets.

- Q: What kind of screws do you choose for stainless steel plates?

- Because boards are often used for decoration, the best choice is not to be fixed with screwsJust use good glue, OKIf the plate is for other purposes, if the demand is not high, ordinary will do

- Q: How do you drill holes in stainless steel sheets?

- To drill holes in stainless steel sheets, you will need to use a high-quality drill bit specifically designed for stainless steel. It is advisable to use a drill press or a stable drilling platform to ensure accuracy and prevent slippage. To reduce heat and friction, lubricate the drill bit with cutting fluid or a suitable lubricant. Begin by marking the desired hole locations on the sheet with a center punch, then start drilling at a slow speed, gradually increasing the speed as you progress. Be cautious not to apply excessive pressure to avoid damaging the sheet or causing the drill bit to break.

- Q: What is the fire resistance rating of stainless steel sheets?

- Stainless steel sheets lack an inherent fire resistance rating as they are not naturally fire resistant materials. Nevertheless, stainless steel can demonstrate commendable fire resistance attributes due to its high melting point and low thermal conductivity. Consequently, stainless steel sheets are less prone to melting or transferring heat during a fire, thus impeding the spread of flames. Furthermore, stainless steel possesses corrosion resistance, which further bolsters its performance in fire scenarios. However, it should be emphasized that the fire resistance of a structure or system hinges on a combination of diverse factors, encompassing the comprehensive design, construction, and utilization of fire-resistant materials. Consequently, the fire resistance rating of stainless steel sheets may fluctuate depending on the specific application and the overarching fire protection measures implemented.

Send your message to us

Cold Rolled Steel Coils Grade 304L NO.2B Finish with High Quality China best Seller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords