Cold Rolled Steel Coils 2B Finish Made In China Grade 304

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

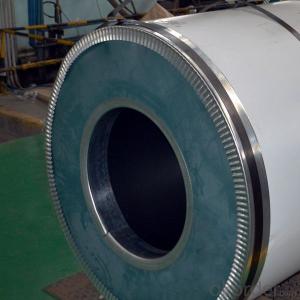

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

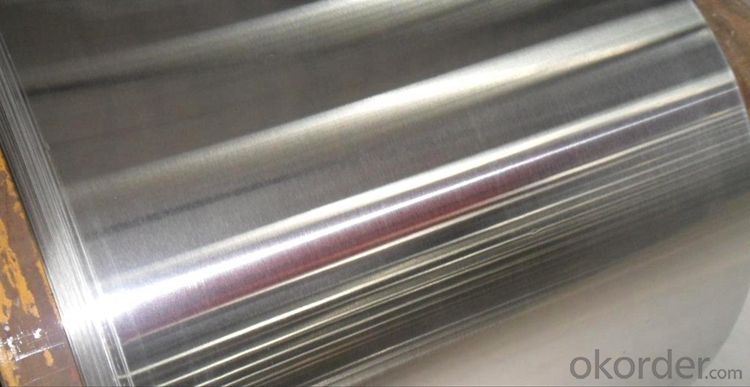

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: What are the different types of stainless steel sheet finishes for architectural applications?

- There are several different types of stainless steel sheet finishes that are commonly used in architectural applications. These finishes are applied to the surface of the stainless steel sheet to enhance its appearance and provide additional protection against corrosion and wear. 1. No. 1 Finish: This is the most common type of stainless steel sheet finish. It is also known as "hot rolled annealed and pickled" finish. In this finish, the stainless steel sheet is hot rolled, resulting in a dull, rough surface. It is then annealed and pickled to remove any scale or impurities, leaving a clean, uniform surface. 2. No. 2B Finish: This finish is achieved by cold rolling the stainless steel sheet after it has been annealed and pickled. It results in a smooth, reflective surface with a slight grainy texture. No. 2B finish is commonly used for applications that require a high level of corrosion resistance and a polished appearance. 3. No. 4 Finish: Also known as "brushed finish," No. 4 finish is achieved by mechanically polishing the stainless steel sheet with abrasive belts or brushes. It creates a satin-like appearance with fine parallel lines. No. 4 finish is often used for decorative purposes in architectural applications such as wall panels, elevator interiors, and column covers. 4. No. 8 Mirror Finish: This finish is achieved by mechanically polishing the stainless steel sheet to a highly reflective mirror-like surface. It provides a bright, reflective appearance and is commonly used for decorative applications such as wall cladding, signage, and decorative trim. 5. Bead Blasted Finish: In this finish, the stainless steel sheet is blasted with fine glass beads to create a textured, matte surface. Bead blasted finish offers a unique aesthetic and is often used in applications where a non-reflective, tactile surface is desired, such as elevator doors, handrails, and countertops. 6. Patterned Finish: Patterned finishes are achieved by embossing or etching the stainless steel sheet with various patterns or textures. This creates a decorative surface that adds visual interest to architectural applications. Patterned finishes are commonly used for wall panels, ceiling tiles, and decorative screens. These are just a few of the most common stainless steel sheet finishes used in architectural applications. Each finish offers its own unique aesthetic and functional characteristics, allowing architects and designers to choose the most suitable finish for their specific project requirements.

- Q: Can stainless steel sheets be used for jewelry?

- Yes, stainless steel sheets can be used for jewelry. Stainless steel is a popular material choice in the jewelry industry due to its durability, resistance to rust and corrosion, and affordability. It is commonly used to create various types of jewelry, including rings, bracelets, earrings, necklaces, and pendants. Stainless steel sheets can be shaped, cut, and polished to create unique and stylish jewelry designs. Additionally, stainless steel jewelry is hypoallergenic, making it an excellent option for individuals with sensitive skin. Overall, stainless steel sheets are a versatile and practical material for creating beautiful and long-lasting jewelry pieces.

- Q: How do you restore the shine or finish on stainless steel sheets?

- To restore the shine or finish on stainless steel sheets, there are a few methods you can try: 1. Cleaning with warm water and soap: Start by cleaning the stainless steel sheets with warm water and a mild dish soap. Use a soft cloth or sponge to gently scrub the surface, then rinse with clean water and dry thoroughly with a clean cloth. This should remove any dirt or grime that is dulling the shine. 2. Vinegar solution: If the stainless steel sheets have stubborn stains or dull spots, you can try using a vinegar solution. Mix equal parts white vinegar and water in a spray bottle, then spray the solution onto the surface. Let it sit for a few minutes, then wipe it off with a soft cloth. Vinegar helps to remove stains and restore shine to stainless steel. 3. Baking soda paste: For tougher stains or scratches on stainless steel sheets, you can create a paste using baking soda and water. Mix enough baking soda with water to form a thick paste, then apply it to the stained areas. Gently scrub the surface with a soft cloth or sponge, moving in the direction of the grain. Rinse with water and dry thoroughly. 4. Stainless steel cleaner: There are commercial stainless steel cleaners available that are specifically designed to restore the shine and finish of stainless steel. Follow the instructions on the cleaner and apply it to the surface using a soft cloth or sponge. Rub gently in the direction of the grain and rinse with water. Dry thoroughly to avoid water spots. Remember, always test any cleaning method or solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will help ensure that the method or solution does not cause any damage or discoloration.

- Q: Can stainless steel sheets be used in decorative applications?

- Certainly, decorative applications can certainly make use of stainless steel sheets. Stainless steel possesses great versatility, allowing it to be shaped, patterned, and finished in a variety of ways, rendering it an exceptional option for decorative purposes. Its sleek and contemporary look adds a dash of sophistication to any area, and it can be utilized in a multitude of ways, such as wall cladding, backsplashes, cabinet fronts, countertops, and furniture embellishments. Moreover, stainless steel sheets exhibit remarkable durability, resistance to corrosion, and ease of maintenance, making them an ideal choice for both indoor and outdoor decorative applications.

- Q: How can I classify stainless steel plates?

- Classification according to the use of stainless steel, can be divided into: the bridge plate, boiler plate, shipbuilding plate, armor plate, automotive steel, steel roof, structural steel, electrical steel (steel sheet), special spring steel, solar panels (hoilik steel).

- Q: Are stainless steel sheets suitable for water treatment applications?

- Water treatment applications can greatly benefit from the use of stainless steel sheets. The reason for this is that stainless steel has exceptional resistance to corrosion, making it the perfect material for environments where there is a presence of water and moisture. It is able to withstand rust, staining, and pitting, guaranteeing the sheets' longevity and durability in water treatment facilities. Moreover, stainless steel sheets possess hygienic qualities. They are effortless to clean and maintain, which is especially crucial in water treatment applications where cleanliness and sanitation are of the utmost importance. Additionally, stainless steel does not react with water, meaning it does not release harmful substances into the water being treated. In addition to these benefits, stainless steel sheets exhibit strength and can tolerate high pressures and temperatures. This is highly significant in water treatment processes that involve filtration, disinfection, and other treatment methods that may require rigorous conditions. To conclude, stainless steel sheets are an outstanding option for water treatment applications due to their resistance to corrosion, hygienic properties, strength, and durability. They present a dependable and long-lasting solution for various components in water treatment facilities, including tanks, pipes, valves, and other equipment.

- Q: Can stainless steel sheets be used for kitchen backsplashes?

- Yes, stainless steel sheets can be used for kitchen backsplashes. Stainless steel is a popular choice for kitchen backsplashes due to its durability, resistance to heat and moisture, and easy maintenance. It provides a sleek and modern look to the kitchen while also protecting the wall from splatters and stains. Additionally, stainless steel sheets are available in various finishes, such as brushed, mirrored, or patterned, allowing homeowners to choose the style that best complements their kitchen design.

- Q: Are stainless steel sheets resistant to alkaline solutions?

- Yes, stainless steel sheets are generally resistant to alkaline solutions.

- Q: Can stainless steel sheets be used for elevator cladding?

- Indeed, elevator cladding can make use of stainless steel sheets. Stainless steel proves to be a favored material for this purpose as it possesses qualities of endurance, resistance to corrosion, and an aesthetically pleasing appearance. Architects and designers often favor stainless steel for elevators due to its ability to provide a sleek and contemporary look. Various finishes, including brushed, mirrored, or patterned, are available for stainless steel sheets, offering customization and design flexibility. Moreover, stainless steel is easily cleaned and maintained, making it a practical choice for high-traffic areas like elevators. In summary, stainless steel sheets present a durable and visually appealing solution for elevator cladding.

- Q: What is the tensile modulus of stainless steel sheets?

- The tensile modulus of stainless steel sheets typically ranges from 180 to 200 GPa (Gigapascals).

Send your message to us

Cold Rolled Steel Coils 2B Finish Made In China Grade 304

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords