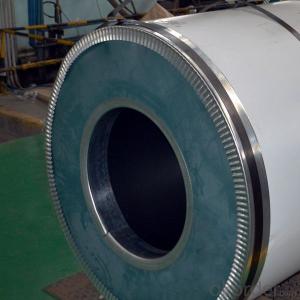

Cold Rolled Stainless Steel sheets NO.2B Finish Grade 304 Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

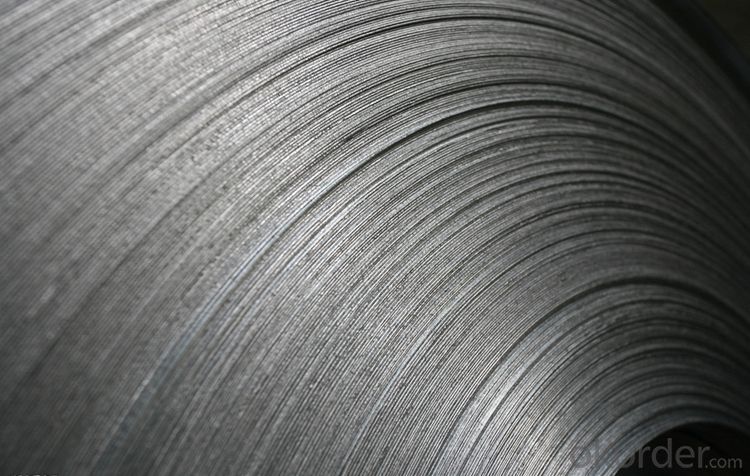

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

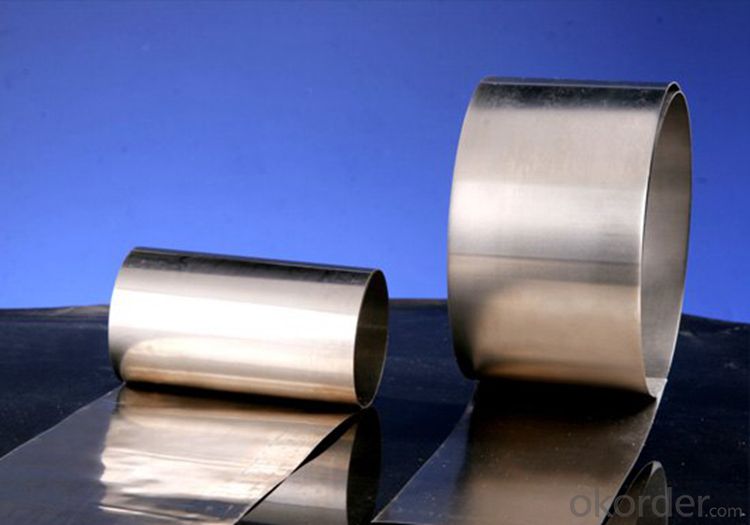

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: 304 how can the water stain on the surface of stainless steel plate be formed?

- This is mainly the unclean environment and surface protection measures are not done well, stainless steel plate surface water stains even if frosted, not necessarily can be worn off

- Q: How do you prevent distortion when welding stainless steel sheets?

- In order to prevent distortion while welding stainless steel sheets, it is important to follow several key steps and precautions: 1. Begin by ensuring that the stainless steel sheets are thoroughly cleaned and free from any contaminants, such as oil, grease, or dirt. Use an appropriate solvent or degreaser to clean the surfaces before welding. This will help to avoid trapping impurities in the weld, which can cause distortion. 2. Accurate fit-up of the stainless steel sheets is crucial to minimize distortion. Make sure that the edges of the sheets are properly aligned and that there are no gaps or misalignments. Proper clamping or tacking can also help to maintain the correct position of the sheets during welding. 3. Controlling the heat input is essential to prevent excessive distortion. Use the appropriate welding technique, such as TIG or MIG, to control the heat. Avoid overheating the stainless steel sheets, as this can lead to warping and distortion. It is important to maintain a consistent and controlled heat input throughout the welding process. 4. Plan the weld sequence properly to minimize distortion. Start from the center and work outward in a balanced manner to distribute the heat evenly. This will prevent localized heating, which can cause distortion. Alternating between sides and allowing each weld to cool before moving to the next one can also help reduce distortion. 5. Choose the right welding technique and parameters. For example, using a lower heat input, slower travel speed, and smaller weld bead can minimize distortion. Additionally, using a backstep technique, where the weld travels in a forward and backward motion, can help distribute the heat and reduce distortion. 6. Consider preheating the stainless steel sheets to reduce the temperature gradient and minimize distortion. Ensure that the preheating temperature is within the recommended range for the specific stainless steel grade. After welding, it is advisable to perform post-weld treatment, such as stress relieving, to minimize residual stresses that can lead to distortion. By following these steps and precautions, it is possible to significantly reduce distortion when welding stainless steel sheets. However, it is important to note that each welding process and stainless steel grade may have specific requirements. Therefore, it is recommended to refer to the manufacturer's guidelines and seek professional advice for optimal results.

- Q: Are stainless steel sheets suitable for storage cabinets?

- Yes, stainless steel sheets are suitable for storage cabinets. They are strong, durable, and resistant to corrosion, making them ideal for long-term storage. Additionally, stainless steel has a sleek and modern appearance, making it a popular choice for both residential and commercial storage cabinets.

- Q: What are the different types of stainless steel sheet perforations available?

- There are several types of stainless steel sheet perforations available, including round, square, slotted, hexagonal, and decorative patterns. These perforations vary in shape, size, and spacing, providing different aesthetics and functionality for various applications.

- Q: What are the different types of stainless steel sheet edges available?

- There are several different types of stainless steel sheet edges available, each offering its own unique advantages and characteristics. 1. Mill Edge: This is the standard edge finish produced during the manufacturing process. It has a straight, sharp edge with no additional treatment or finishing. Mill edge stainless steel sheets are commonly used in industrial applications where aesthetics are not a priority. 2. Slit Edge: Slit edge stainless steel sheets are created by cutting the sheet along its length, resulting in a slightly rounded edge. This type of edge is commonly used in applications where safety is a concern, as it reduces the risk of sharp edges causing injury. 3. Sheared Edge: Sheared edge stainless steel sheets are created by cutting the sheet along its width using shearing blades. This process produces a clean, straight edge without any additional finishing. Sheared edge sheets are often used in applications where precise dimensions are required. 4. Deburred Edge: Deburred edge stainless steel sheets have gone through a process to remove any sharp or rough edges, resulting in a smooth and safe edge finish. Deburring is often done using abrasive materials or specialized machinery. These sheets are commonly used in applications where safety and aesthetic appearance are both important. 5. Rolled Edge: Rolled edge stainless steel sheets have a curved or rounded edge, created by rolling the sheet during the manufacturing process. This edge type is commonly used in applications where a smoother, more finished appearance is desired. Rolled edge sheets are also easier to handle and less likely to cause injury during installation. Overall, the choice of stainless steel sheet edge depends on the specific requirements of the application, including safety concerns, aesthetic preferences, and dimensional accuracy.

- Q: Can stainless steel sheets be used for wastewater treatment?

- Yes, stainless steel sheets can be used for wastewater treatment. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions and corrosive elements often found in wastewater treatment processes. Additionally, its smooth surface makes it easy to clean and maintain, ensuring long-term durability and effectiveness in treating wastewater.

- Q: What are the advantages of using stainless steel sheets in the medical industry?

- Using stainless steel sheets in the medical industry offers several benefits: 1. Maintaining Hygiene and Cleanliness: Stainless steel's non-porous nature makes it easy to clean and disinfect, making it an excellent option for medical equipment, surgical instruments, and hospital furniture. It resists bacteria, mold, and other pathogens, ensuring a hygienic environment. 2. Ensuring Longevity and Durability: Stainless steel can withstand harsh conditions, including high temperatures, humidity, and corrosive substances. This durability extends the lifespan of medical equipment and instruments, reducing the need for frequent replacements. 3. Providing Strength and Safety: Stainless steel sheets offer exceptional strength and structural integrity, making them suitable for applications that require resistance to impact and pressure. This is crucial in the medical industry, where instruments and equipment are constantly utilized and handled. 4. Resisting Stains and Corrosion: Stainless steel is highly resistant to stains and corrosion, even in aggressive environments. This property is essential in medical facilities where exposure to various chemicals and liquids is common. The resistance to corrosion ensures that stainless steel sheets remain intact and do not release harmful substances into the environment. 5. Enhancing Aesthetic Appeal: Stainless steel sheets have a sleek and modern appearance that contributes to the overall aesthetic appeal of medical equipment and instruments. This creates a positive impression on patients, instilling confidence in the quality and cleanliness of the medical facility. 6. Promoting Recyclability: Stainless steel is a sustainable material that can be recycled without any loss in quality. This reduces the environmental impact of the medical industry by minimizing waste and conserving resources. In conclusion, stainless steel sheets offer advantages such as hygiene, durability, strength, resistance to stains and corrosion, aesthetic appeal, and recyclability. These qualities make stainless steel a reliable and cost-effective choice for medical equipment, instruments, and other applications in healthcare settings.

- Q: Can stainless steel sheets be used for pressure vessels?

- Yes, stainless steel sheets can be used for pressure vessels. Stainless steel is known for its excellent corrosion resistance, which makes it an ideal material for pressure vessels that are exposed to harsh environments or corrosive substances. It also has high strength and good mechanical properties, allowing it to withstand the internal pressure exerted by the fluid or gas inside the vessel. Additionally, stainless steel sheets can be easily formed and welded to create the desired shape and size of the pressure vessel. Overall, stainless steel sheets are a popular choice for pressure vessels in various industries such as oil and gas, chemical processing, and pharmaceuticals.

- Q: Stainless steel thermos cup 304 and 201 material what is the difference?

- 304 stainless steel corrosion resistance, high prices: 201 and 304 stainless steel material in essence difference, mainly in the elements contained in the two are not the same. 304 stainless steel corrosion resistance and stamping performance far better than 201, and the 304 stainless steel is generally used in the complex environment, need strong resistance to corrosion for 201 place, environmental requirements are not very high, or the stainless steel demand is not high place.

- Q: Can stainless steel sheets be used for jewelry making?

- Yes, stainless steel sheets can be used for jewelry making. Stainless steel is a durable and hypoallergenic material that is often used in the production of jewelry. It offers a sleek and modern look and can be easily shaped and manipulated into various designs and forms for making earrings, necklaces, bracelets, and other jewelry pieces.

Send your message to us

Cold Rolled Stainless Steel sheets NO.2B Finish Grade 304 Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords