Stainless Steel sheets Grade 304,Stainless Steel Coils NO.2B Finish made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

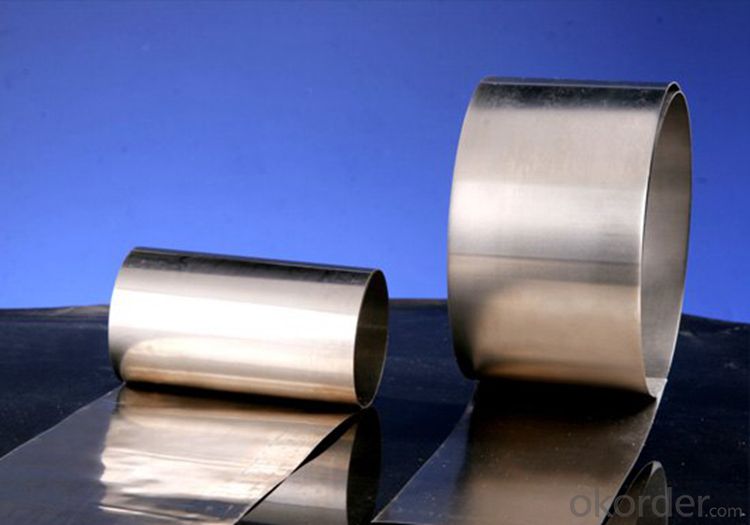

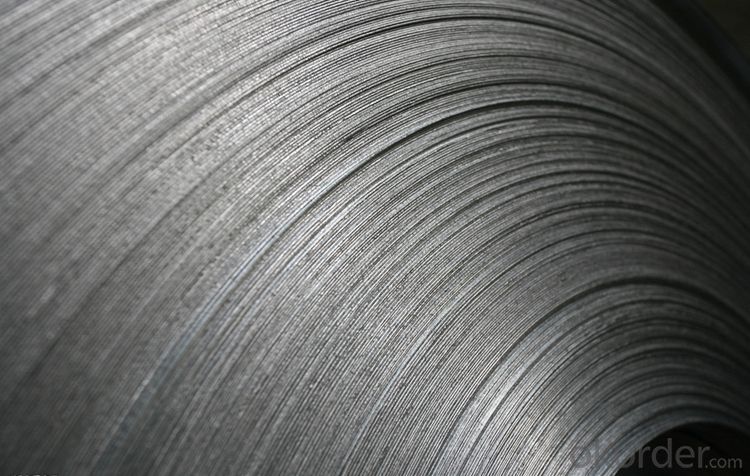

Stainless Steel sheets Grade 304,Stainless Steel Coils NO.2B Finish

Made in China

Products Description

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How do you prevent warping or distortion in stainless steel sheets?

- To prevent warping or distortion in stainless steel sheets, several measures can be taken. First, it is important to properly handle and store the sheets to prevent any bending or twisting during transportation or storage. Secondly, ensuring a smooth and even distribution of heat during welding or fabrication processes can help minimize the chances of warping. Additionally, using proper clamping techniques and supports during machining or cutting operations can help maintain the shape and integrity of the stainless steel sheets. Lastly, adhering to the recommended thicknesses and specifications provided by the manufacturer for specific applications can also help prevent warping or distortion in stainless steel sheets.

- Q: What are the different welding techniques used for stainless steel sheets?

- Various welding techniques are commonly employed for stainless steel sheets, each offering distinct advantages and considerations. 1. TIG Welding (Gas Tungsten Arc Welding): TIG welding, a versatile and precise method, proves suitable for thin stainless steel sheets. It involves using a non-consumable tungsten electrode to generate an electric arc that melts and fuses the metals. High-quality welds with minimal heat distortion and excellent aesthetic appearance are ensured. 2. MIG Welding (Gas Metal Arc Welding): MIG welding, known for its efficiency and user-friendliness, is a popular choice for stainless steel sheets. It employs a consumable electrode wire and an inert gas shield to protect the weld from atmospheric contamination. MIG welding exhibits faster speed than TIG welding and performs well on thicker stainless steel sheets. 3. Spot Welding: Joining two stainless steel sheets together, spot welding applies pressure and heat using electrodes. This technique finds common use in applications where a continuous seam is unnecessary, such as in automotive manufacturing or appliance production. 4. Plasma Arc Welding: Similar to TIG welding, plasma arc welding employs a more concentrated arc produced by a constricted nozzle. This technique allows for deeper penetration on stainless steel sheets, making it suitable for thicker materials or specialized applications. 5. Laser Welding: Laser welding, a precise and rapid technique, employs a high-powered laser beam to melt and join stainless steel sheets. It offers exceptional control over the welding process and proves suitable for thin to medium thickness stainless steel sheets. However, laser welding may require specialized equipment and expertise. The choice of welding technique depends on various factors, including the thickness of the stainless steel sheets, desired weld quality, production speed, and equipment availability. Each technique possesses its own advantages and limitations.

- Q: What are the different finishes available for stainless steel sheets?

- Some common finishes available for stainless steel sheets include brushed, mirror, satin, and textured finishes.

- Q: Can stainless steel sheets be used in swimming pool applications?

- Yes, stainless steel sheets can be used in swimming pool applications. Stainless steel is known for its corrosion resistance, making it a suitable material for prolonged exposure to water and chemicals typically found in swimming pools. It is also easy to clean and maintain, making it a popular choice for pool construction and renovation projects.

- Q: How do I prevent discoloration on stainless steel sheets?

- To prevent discoloration on stainless steel sheets, it is important to regularly clean and maintain them. Use a soft cloth or sponge along with mild soap or a stainless steel cleaner to remove any dirt or grime. Avoid using abrasive cleaners or scrubbing pads, as they can scratch the surface. Additionally, be cautious of exposing stainless steel sheets to harsh chemicals or acidic substances, as they can cause discoloration.

- Q: Can stainless steel sheets be used for cryogenic applications?

- Yes, stainless steel sheets can be used for cryogenic applications. Stainless steel is known for its excellent mechanical properties, corrosion resistance, and low thermal conductivity, which make it suitable for cryogenic environments. It can withstand the extreme cold temperatures without becoming brittle or losing its strength. Stainless steel sheets are commonly used in cryogenic applications such as storage tanks, piping systems, and cryogenic equipment. However, it is important to choose the appropriate grade of stainless steel that is specifically designed for cryogenic applications to ensure optimal performance and durability.

- Q: What are the different types of surface treatments available for stainless steel sheets?

- There are several types of surface treatments available for stainless steel sheets, including mirror finish, brushed finish, satin finish, etched finish, embossed finish, and colored finish. These treatments can enhance the appearance, durability, and corrosion resistance of stainless steel sheets, catering to various aesthetic and functional requirements.

- Q: Can stainless steel sheets be used for electrical or electronic applications?

- Yes, stainless steel sheets can be used for electrical or electronic applications. Stainless steel has excellent electrical conductivity and is resistant to corrosion, making it an ideal material for various electrical components. It is commonly used in electrical enclosures, switchgear, control panels, and other electrical equipment. Additionally, stainless steel sheets can be fabricated into different shapes and sizes, making them suitable for various electronic applications such as printed circuit boards (PCBs), connectors, and terminals. The durability and high temperature resistance of stainless steel also make it a preferred choice for electrical and electronic applications in harsh environments.

- Q: Are stainless steel sheets resistant to hydrogen embrittlement?

- Stainless steel sheets are commonly resistant to hydrogen embrittlement. Hydrogen embrittlement refers to the brittleness and susceptibility to cracking caused by the diffusion of hydrogen atoms into the metal structure. Nonetheless, stainless steel has a strong resistance to hydrogen embrittlement due to its distinct composition and microstructure. The presence of chromium in stainless steel produces a protective oxide layer on the surface, acting as a barrier against hydrogen diffusion. Furthermore, stainless steel sheets are often alloyed with elements like nickel and molybdenum, further enhancing their resistance to hydrogen embrittlement. However, it is important to note that certain conditions, such as high temperatures or high levels of hydrogen exposure, can still potentially result in hydrogen embrittlement in stainless steel. Hence, it is crucial to consider the specific application and operating conditions when determining the suitability of stainless steel sheets in relation to hydrogen embrittlement.

- Q: Are stainless steel sheets resistant to sulfuric acid?

- Yes, stainless steel sheets are generally resistant to sulfuric acid.

Send your message to us

Stainless Steel sheets Grade 304,Stainless Steel Coils NO.2B Finish made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords