Cold Drawn Die Steel,Tool Steel Bar 1.2510

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold Drawn Die Steel,Tool Steel Bar 1.2510

Product information:

1.Cold working die steel.

2.Wiht highest hardness and abrasion resistance in the Cr12 and 9SiCr.

3.Low impact toughness,should avoid tempering at about 300°c.

4.should do the resonable structure .

| Shape | Round | Diameter: 10mm~700mm |

| Flat | Thickness: 20mm-400mm | |

| Width: 60mm-600mm | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; tempered | |

| Surface Condition | Black surface ; Grinded ; Machined | |

| Delivery Condition | hot rolled ; cold drawn ; forged | |

| Payment Terms | T/T; L/C | |

| Trade Terms | FOB; CIF | |

| Application | cold work die steel; hot work die steel; plastic die steel | |

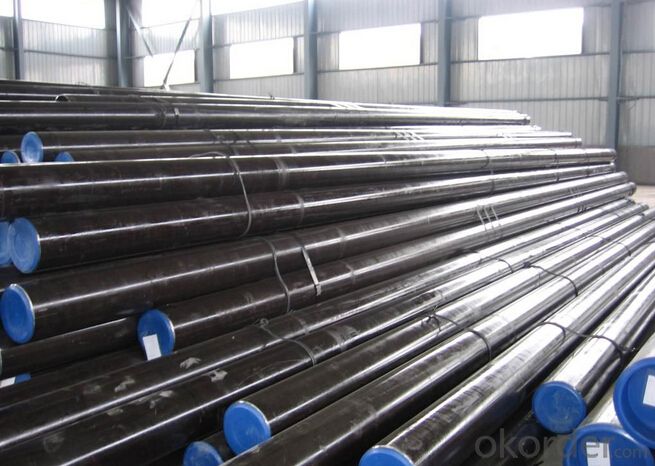

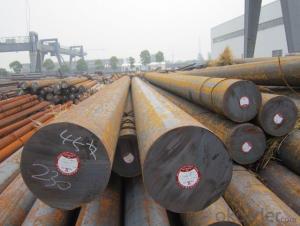

Product show:

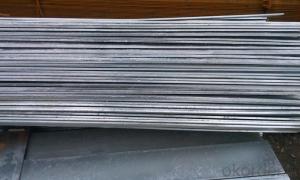

Workshop show:

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: How is high-temperature stainless steel used in the production of gas turbines?

- High-temperature stainless steel is used in the production of gas turbines due to its excellent heat resistance and corrosion properties. It is used to fabricate components such as combustion chambers, turbine blades, and exhaust systems, which are exposed to extreme temperatures and corrosive environments. The high-temperature stainless steel ensures the durability and efficiency of gas turbines, allowing them to operate at high temperatures without compromising performance or longevity.

- Q: Can special steel be used for manufacturing tools?

- Yes, special steel can definitely be used for manufacturing tools. Special steel refers to a specific type of steel that is carefully engineered and designed to possess certain properties and characteristics that make it suitable for specific applications. In the case of manufacturing tools, special steel is often preferred due to its exceptional strength, hardness, and durability. These properties enable tools made from special steel to withstand high levels of stress, wear, and impact, making them ideal for demanding applications such as cutting, drilling, shaping, and machining. Additionally, special steel can also exhibit excellent heat resistance, corrosion resistance, and dimensional stability, further enhancing its suitability for tool manufacturing. Overall, the use of special steel in tool production ensures the creation of high-quality, long-lasting, and efficient tools that can effectively perform various tasks in different industries.

- Q: What are the different quality control measures for special steel production?

- There are several quality control measures implemented during special steel production, including rigorous inspections at various stages of the manufacturing process, such as raw material testing, chemical composition analysis, and heat treatment verification. Additionally, non-destructive testing techniques, such as ultrasonic testing and magnetic particle inspection, are employed to detect any defects or inconsistencies in the steel's structure. Furthermore, dimensional and surface quality checks are performed to ensure that the final product meets the required specifications and standards.

- Q: How is special steel used in the manufacturing of cutting tools?

- Special steel is used in the manufacturing of cutting tools due to its exceptional properties such as high hardness, wear resistance, and toughness. This type of steel allows for the production of durable and efficient cutting tools that can withstand the high forces and temperatures involved in cutting operations. Additionally, special steel can be heat-treated to further enhance its properties, making it ideal for creating sharp and long-lasting cutting edges.

- Q: How does special steel contribute to sustainable construction?

- Special steel contributes to sustainable construction in several ways. Firstly, it has high strength and durability, which allows for the design and construction of lighter and more efficient structures. This reduces the amount of material needed and saves resources. Secondly, special steel is often made from recycled materials, reducing the demand for virgin resources and minimizing environmental impact. Additionally, special steel can be easily recycled at the end of its life cycle, promoting a circular economy and reducing waste. Overall, special steel helps to create sustainable buildings by improving energy efficiency, reducing carbon emissions, and conserving resources.

- Q: How does special steel contribute to the manufacturing of springs?

- Special steel contributes to the manufacturing of springs by providing specific mechanical properties that are crucial for their functionality. The unique composition and heat treatment of special steel ensure excellent strength, durability, and elasticity, allowing springs to efficiently store and release energy. Additionally, special steel's resistance to corrosion and fatigue enhances the lifespan and reliability of springs, making them suitable for various applications in industries such as automotive, aerospace, and machinery.

- Q: What are the main applications of special steel in the packaging industry?

- The main applications of special steel in the packaging industry include the manufacturing of containers, cans, and closures. Special steel offers excellent strength, durability, and corrosion resistance, making it suitable for packaging materials that need to withstand various environmental conditions and protect the contents inside. Its high tensile strength also allows for thinner and lighter packaging, reducing material usage and transportation costs. Additionally, special steel is used in machinery and equipment used for packaging processes, ensuring efficiency and reliability in the production line.

- Q: What are the specific requirements for special steel used in the oil and gas pipeline industry?

- The specific requirements for special steel used in the oil and gas pipeline industry are dictated by the harsh operating conditions and the need for high performance and reliability. Some of the key requirements include: 1. Corrosion resistance: Special steel used in the oil and gas pipeline industry must possess excellent resistance to corrosion, as pipelines are exposed to various corrosive elements such as moisture, gases, and chemicals. This helps to prevent the degradation or failure of the pipeline due to corrosion. 2. High strength: The steel used in pipelines must have high tensile strength to withstand the high pressure and stress that it experiences during transportation of oil and gas. This ensures the pipeline's structural integrity and prevents leaks or bursts. 3. Toughness and impact resistance: The steel must be able to absorb energy and resist fracture when subjected to sudden impact or external forces. This is crucial for maintaining pipeline integrity and preventing accidents or ruptures. 4. Low temperature toughness: As pipelines often operate in cold environments, the steel must exhibit excellent low-temperature toughness to prevent brittle fracture. This ensures that the pipeline remains ductile and resistant to failure even at extremely low temperatures. 5. Weldability: Special steel used in pipelines should be easily weldable to facilitate the construction and repair of pipelines. Good weldability ensures strong and reliable joints that can withstand the stress and pressure during operation. 6. Resistance to hydrogen-induced cracking: Steel used in the oil and gas pipeline industry should have high resistance to hydrogen-induced cracking (HIC) and sulfide stress cracking (SSC). These types of cracks can occur when hydrogen or sulfide ions penetrate the steel, leading to catastrophic failure. Resistance to these types of cracking is crucial for pipeline safety. 7. Compliance with industry standards: Special steel used in the oil and gas pipeline industry must meet specific industry standards and regulations. These standards ensure that the steel meets the required mechanical properties, chemical composition, and manufacturing processes necessary for safe and reliable pipeline operation. Overall, the specific requirements for special steel used in the oil and gas pipeline industry are aimed at ensuring corrosion resistance, high strength, toughness, low-temperature performance, weldability, resistance to cracking, and compliance with industry standards. These requirements are essential for maintaining the integrity and safety of oil and gas pipelines.

- Q: How is high-speed tool steel used in the manufacturing of drills and taps?

- High-speed tool steel is used in the manufacturing of drills and taps because of its exceptional hardness, wear resistance, and heat resistance properties. This type of steel allows drills and taps to withstand high temperatures and friction, ensuring their durability and longevity. Additionally, high-speed tool steel enables these cutting tools to maintain their sharpness for longer periods, resulting in increased efficiency and precision during drilling and tapping operations.

- Q: What are the main challenges in welding special steel?

- The main challenges in welding special steel typically include issues such as high heat input requirements, susceptibility to cracking, and the need for precise preheating and post-weld heat treatment. Additionally, the presence of alloying elements in special steel can make it more difficult to achieve the desired mechanical properties and require careful selection of filler materials.

Send your message to us

Cold Drawn Die Steel,Tool Steel Bar 1.2510

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords