1.2080 Cold Work Die Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.2080 Cold Work Die Steel Round Bar

Specifications

1. 2080

1. cold work mould/die steel

2. High carbon high chromium type ledeburite

3. High hardness wear resistance

Product description

1. Cr12 steel is a widely used cold work die steel, a type of high carbon high chromium ledeburite . The steel has good hardenability and good abrasion resistance

2. Mainly used to with stand the impact load is smaller, and require high abrasion resistance Die and punch, cold-cut scissors, drill sets, gauges, drawing die, pressure die thread rolling board, drawing die thread rolling die.

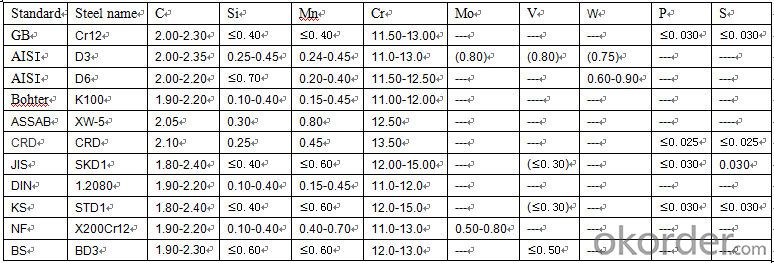

Chemical composition(for reference only)

Delivery of hardness and quenching hardness

Steel name | Delivery status | Quenched specimens | |||

Hardness HBW | Impressiondiameter (mm) | Quenching temperature/°C | Cooling medium | hardness ≥HRC | |

Cr12 | 269~217 | 3.7~4.1 | 950~1000 | oil | 60 |

Physical properties

Cr12 critical temperature

Critical point | Ac1 | Acm | Ar1 | Arcm | Ms |

temperature(approximation)/°C | 810 | 835 | 755 | 770 | 180 |

Cr12 Hot Working Technology

Item | Heating temperature/°C | start forging temperature/°C | final forging temperature/°C | type of cooling |

Steel ingot | 1140~1160 | 1100~1120 | 900~920 | Slow cooling |

Steel billet | 1120~1140 | 1080~1100 | 880~920 | Slow cooling |

Cr12 heat treatment

between the quenching temperature and the hardness of the relationship

quenching temperature/°C | 875 | 900 | 925 | 950 | 975 | 1000 | 1050 | 1100 |

Hardness HRC | 54.5 | 57 | 60 | 62.5 | 65 | 66 | 64 | 59.5 |

Delivery status: steel delivered in the annealed condition

We are professional manufacture of tool steel. We can provide various kinds of tool steel and mould steel. If you have any question regarding our products ,please feel free to let us know. We assure you will receive our best attention to your enquiry.

Products

- Q: What is the maximum length available for steel round bars?

- The maximum length available for steel round bars can vary depending on the supplier and the specific requirements, but typically it can range from 12 to 24 feet.

- Q: Can steel round bars be used for making steering linkages?

- Making steering linkages is one application where steel round bars can be used. Steel round bars have a wide range of uses in automotive and mechanical engineering due to their strength, durability, and resistance to wear and tear. Steering linkages play a crucial role in a vehicle's steering system as they transmit the steering input from the steering wheel to the wheels. By using steel round bars, the necessary strength and rigidity are provided, ensuring efficient and reliable steering performance. However, it is important to consider other factors like specific design requirements, weight considerations, and desired level of flexibility or torsional properties when choosing the appropriate type and size of steel round bar for steering linkages.

- Q: What is the difference between a seamless and a precision ground steel round bar?

- A seamless steel round bar is manufactured without any seams or welds, resulting in a smooth and uniform surface throughout the entire length. On the other hand, a precision ground steel round bar is manufactured with precise dimensions and surface finish, typically achieved through grinding or machining processes. This ensures tighter tolerances and a more accurate diameter, making it suitable for applications requiring high precision and tight dimensional control.

- Q: What are the advantages of using chromium-vanadium alloy steel round bars?

- Using chromium-vanadium alloy steel round bars has several advantages: 1. Exceptional Strength and Hardness: Chromium-vanadium alloy steel is renowned for its high strength and hardness. It possesses a strong tensile strength, making it ideal for heavy-duty applications and resistance against wear and tear. 2. Enhanced Durability: The incorporation of chromium and vanadium elements improves the durability of the alloy steel round bars. It offers excellent resistance to corrosion, oxidation, and high temperatures, making it perfect for harsh environments. 3. Versatility in Applications: Chromium-vanadium alloy steel round bars provide versatility in various applications. They are suitable for manufacturing tools, springs, gears, and other components requiring strength and durability. This alloy steel's versatility makes it highly favored in industries like automotive, aerospace, and construction. 4. Convenient Machinability: Chromium-vanadium alloy steel is relatively easy to machine and work with, offering convenience to manufacturers. It can be easily shaped, cut, and formed into desired sizes and shapes without compromising its mechanical properties. 5. Cost-Effective Option: Despite its exceptional properties, chromium-vanadium alloy steel round bars tend to be cost-effective when compared to other high-performance alloys. Hence, it is a popular choice for industries that require strong and durable materials within their budget. 6. Exceptional Fatigue Resistance: Chromium-vanadium alloy steel demonstrates exceptional fatigue resistance, making it suitable for applications involving repetitive stress or cyclic loading. It can withstand repeated use and maintain its structural integrity over an extended period. In conclusion, chromium-vanadium alloy steel round bars offer a combination of high strength, enhanced durability, versatility, and cost-effectiveness. These advantages make it the preferred material choice for various industrial applications where reliability and performance are of utmost importance.

- Q: What are the different types of steel round bar surface treatments used in the aerospace industry?

- In the aerospace industry, there are several types of steel round bar surface treatments that are commonly used to enhance the performance and durability of the materials. These treatments are specifically designed to meet the stringent requirements and standards set by the industry. Some of the different types of steel round bar surface treatments used in the aerospace industry include: 1. Passivation: This treatment involves the removal of iron particles and other contaminants from the surface of the steel round bar. It helps to prevent corrosion and improves the overall corrosion resistance properties of the material. 2. Shot Peening: Shot peening is a process that involves bombarding the surface of the steel round bar with small metallic shots. This treatment induces compressive stress on the surface, which enhances the material's fatigue strength and resistance to stress corrosion cracking. 3. Electroplating: Electroplating is a common surface treatment used in the aerospace industry. It involves the deposition of a layer of metallic coating onto the steel round bar through an electrochemical process. This treatment enhances the material's corrosion resistance, wear resistance, and aesthetic appearance. 4. Anodizing: Anodizing is an electrolytic passivation process that is commonly used on aluminum alloys. However, it can also be used on steel round bars. This treatment forms a thick, durable, and corrosion-resistant layer of oxide on the surface, which improves the material's resistance to wear, corrosion, and scratching. 5. Nitriding: Nitriding is a surface hardening treatment that involves the diffusion of nitrogen into the surface of the steel round bar. This treatment improves the material's surface hardness, wear resistance, and fatigue strength. 6. Chemical Conversion Coating: Chemical conversion coating is a treatment that involves the formation of a thin, protective layer on the surface of the steel round bar. This coating enhances the material's corrosion resistance and provides a good base for subsequent paint or coating applications. These are just a few examples of the different types of steel round bar surface treatments used in the aerospace industry. Each treatment offers unique benefits and is selected based on the specific requirements of the application, such as corrosion resistance, wear resistance, fatigue strength, and aesthetic appearance.

- Q: What are the advantages of using nickel-molybdenum alloy steel round bars?

- There are several advantages of using nickel-molybdenum alloy steel round bars: 1. High strength and durability: Nickel-molybdenum alloy steel round bars have excellent strength and durability properties, making them suitable for use in high-stress applications. They can withstand heavy loads and provide long-lasting performance. 2. Corrosion resistance: The addition of nickel in the alloy enhances its corrosion resistance, making it resistant to various corrosive environments. This makes nickel-molybdenum alloy steel round bars ideal for use in industries where exposure to chemicals or moisture is common, such as the oil and gas industry or marine applications. 3. High temperature resistance: Nickel-molybdenum alloy steel round bars exhibit excellent heat resistance properties, allowing them to maintain their mechanical strength and structural integrity at high temperatures. This makes them suitable for use in applications where elevated temperatures are present, such as heat exchangers or power generation equipment. 4. Excellent machinability: Nickel-molybdenum alloy steel round bars can be easily machined and fabricated, allowing for various customization options. This makes them versatile and easily adaptable to different project requirements. 5. Weldability: These alloy steel round bars have good weldability, which means they can be easily joined to other components or structures using standard welding techniques. This makes them convenient for manufacturing processes and construction projects. 6. Cost-effective: Despite their excellent properties, nickel-molybdenum alloy steel round bars are relatively cost-effective compared to other high-performance alloys. This makes them a cost-efficient choice for various applications, providing value for money without compromising on quality. Overall, the advantages of using nickel-molybdenum alloy steel round bars include high strength, corrosion resistance, temperature resistance, machinability, weldability, and cost-effectiveness. These properties make them a preferred choice for various industries and applications where superior performance and durability are required.

- Q: What are the different grades of heat-treated steel round bars?

- There are several different grades of heat-treated steel round bars, each offering specific properties and characteristics. Some of the common grades include: 1. 4140: This grade of heat-treated steel round bar is known for its high strength and toughness. It has excellent wear resistance, good machinability, and can be easily heat treated to enhance its hardness and strength. 2. 4340: Heat-treated steel round bars of this grade are known for their high tensile strength, toughness, and fatigue resistance. They are commonly used in applications that require high strength and durability, such as aerospace and automotive industries. 3. 8620: This grade of heat-treated steel round bar is characterized by its case hardening properties. It has good core strength, excellent toughness, and is often used in applications that require high wear resistance, such as gears, shafts, and pins. 4. 52100: Heat-treated steel round bars of this grade are widely used in bearing applications due to their excellent hardness, wear resistance, and high fatigue strength. They are specially designed to withstand heavy loads and provide long-lasting performance. 5. 1045: This grade of heat-treated steel round bar is known for its medium carbon content, providing good strength and impact resistance. It is commonly used in applications that require moderate strength and toughness, such as shafts, axles, and machinery parts. These are just a few examples of the different grades of heat-treated steel round bars available in the market. The choice of grade depends on the specific requirements of the application, such as strength, hardness, toughness, and wear resistance. It is important to consult with a knowledgeable professional to determine the most suitable grade for your particular needs.

- Q: What are the disadvantages of using steel round bars?

- There are a few disadvantages associated with using steel round bars. Firstly, steel round bars can be quite heavy, making them difficult to handle and transport. Secondly, steel round bars can corrode if not properly protected, which can lead to structural weakness and reduced lifespan. Additionally, steel round bars may not be suitable for certain applications that require lightweight or non-magnetic materials. Lastly, steel round bars can be more expensive compared to other materials, which may impact the overall project cost.

- Q: What is the difference between a hot-rolled and a cold-drawn steel round bar?

- The manufacturing process and resulting properties distinguish a hot-rolled steel round bar from a cold-drawn one. To produce hot-rolled bars, a billet or ingot is heated to a high temperature, typically around 1100 to 1300 degrees Celsius, and then rolled into the desired shape and size. This process yields a rougher surface finish and larger tolerances compared to cold-drawn bars. Hot-rolled bars exhibit less precision in dimensions and may contain surface defects such as scale or rust. In contrast, cold-drawn bars undergo manufacturing by pulling a hot-rolled bar through a die at room temperature. This process reduces the diameter and enhances the surface finish, resulting in a smoother and more precise product. Cold-drawing also improves the mechanical properties of the steel, including increased strength, hardness, and improved surface quality. The cold-drawing process provides closer dimensional tolerances, making cold-drawn bars suitable for applications that demand higher precision. In conclusion, the distinction between hot-rolled and cold-drawn steel round bars lies in the manufacturing process, resulting in differences in surface finish, dimensional tolerances, and mechanical properties. Hot-rolled bars are produced at high temperatures, possess a rougher surface, and have larger tolerances. On the other hand, cold-drawn bars are manufactured at room temperature, exhibit a smoother surface, closer dimensional tolerances, and enhanced mechanical properties. The choice between the two depends on specific application requirements and the desired characteristics of the final product.

- Q: Are steel round bars suitable for the production of gears?

- Yes, steel round bars are suitable for the production of gears. Steel is a strong and durable material that can withstand high levels of stress and friction, making it ideal for gear manufacturing. Additionally, steel round bars can be easily machined and heat-treated to achieve the required hardness and precision for gear production.

Send your message to us

1.2080 Cold Work Die Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches