Cold Drawn Hexagonal Steel Bar 4140 5140

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

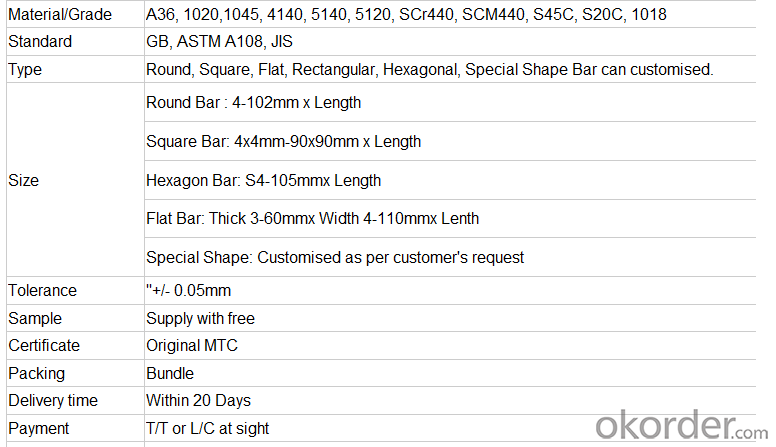

Specification

Cold drawn hexagonal Steel Bar 4140 5140

Product information

1. Produce Standard: GB, AISI, ASTM, SAE, EN, BS, DIN, JIS

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment: Normalized / Annealed / Quenched+Tempered

4. Quality assurance: All order we can received third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product detail

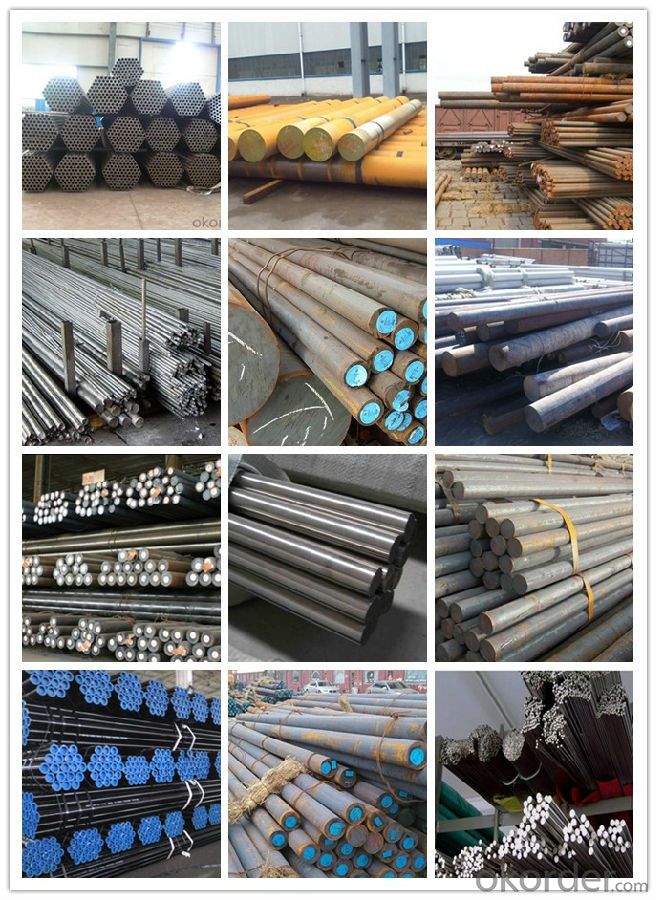

Product show

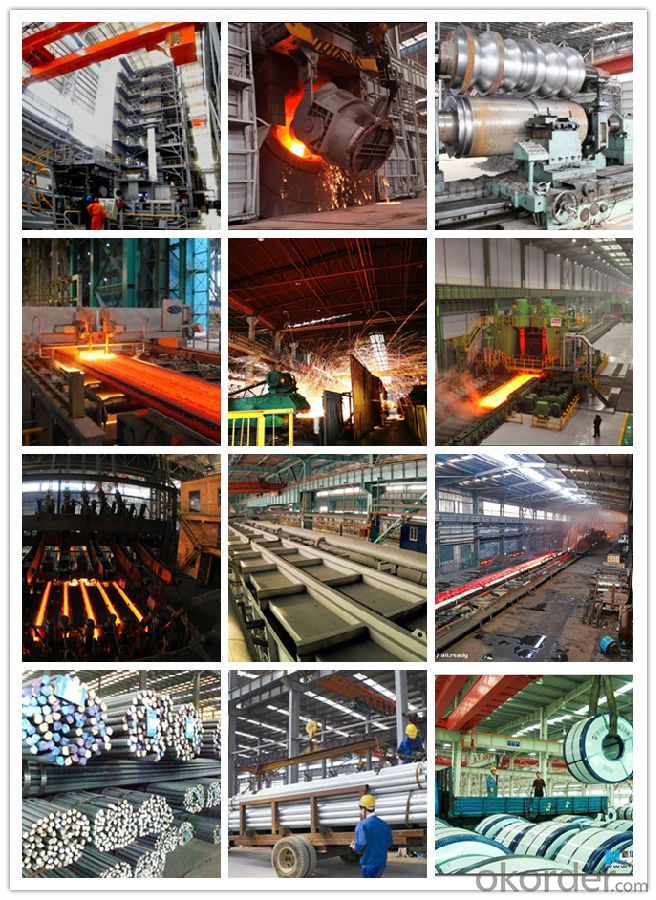

Work shop

Our Services

* Welcome to contact us with your detailed inquiry, you will be replied within 24 hours.

* You are promised to obtain the best quality, price and service.

* We'd like to provide samples for your confirm.

- Q: What are the main applications of special steel in the semiconductor industry?

- Special steel is widely used in the semiconductor industry for various applications. One of the main applications is in the production of wafer fabrication equipment, such as vacuum chambers, deposition tools, and etching systems. The high strength, corrosion resistance, and thermal stability of special steel make it suitable for these critical components that operate under extreme conditions. Additionally, it is also used in the manufacturing of precision molds and dies required for semiconductor packaging processes. Overall, special steel plays a vital role in ensuring the reliability, performance, and quality of semiconductor manufacturing processes.

- Q: How does special steel contribute to the textile industry?

- Special steel contributes to the textile industry by providing high-strength and durable components for textile machinery, such as looms, knitting machines, and textile processing equipment. The use of special steel in these machines ensures improved performance, precision, and longevity, thereby enhancing productivity and efficiency in textile manufacturing processes. Additionally, special steel's resistance to corrosion and wear helps maintain the quality and reliability of textile machinery, minimizing downtime and maintenance costs for manufacturers.

- Q: How does special steel contribute to sustainability efforts?

- Special steel contributes to sustainability efforts in several ways. Firstly, it has a longer lifespan compared to regular steel, which reduces the need for frequent replacements and minimizes waste. Additionally, special steel is often made from recycled materials, reducing the demand for raw resources and decreasing the environmental impact of mining and extraction. Furthermore, its exceptional strength and durability allow for the construction of more energy-efficient buildings and infrastructure, reducing energy consumption and greenhouse gas emissions. Overall, special steel plays a vital role in promoting a more sustainable and eco-friendly approach in various industries.

- Q: Can special steel be used in the electronics industry?

- Yes, special steel can be used in the electronics industry. It is commonly used for various components such as connectors, springs, and contacts due to its high strength, corrosion resistance, and electrical conductivity properties.

- Q: How is special steel used in the production of pressure vessels?

- Special steel is used in the production of pressure vessels due to its high strength, durability, and resistance to corrosion. It ensures the vessel can withstand high internal pressure and harsh operating conditions, ensuring safety and reliability.

- Q: How is leaded steel used in machining operations?

- Leaded steel is commonly used in machining operations due to its improved machinability. The addition of lead to the steel composition enhances its ability to be cut, drilled, and shaped with ease, reducing tool wear and improving surface finish. This type of steel is particularly useful in high-speed machining applications, where efficiency and precision are crucial.

- Q: What are the different types of high-strength steel?

- There are several different types of high-strength steel, including high-strength low-alloy (HSLA) steel, advanced high-strength steel (AHSS), ultra-high-strength steel (UHSS), and maraging steel.

- Q: What are the properties of electrical resistance steel?

- Electrical resistance steel, also known as resistivity steel, possesses high electrical resistance due to its composition and structure. It has the ability to impede the flow of electric current, converting electrical energy into heat. This property makes it suitable for various applications, such as heating elements, resistors, and electrical wirewound resistors. Additionally, electrical resistance steel exhibits good thermal stability and corrosion resistance, making it a reliable choice for electrical and electronic devices.

- Q: Can special steel be used for structural applications?

- Yes, special steel can be used for structural applications. Special steel refers to steel that has been alloyed or modified to possess specific properties such as enhanced strength, durability, or corrosion resistance. These qualities make special steel suitable for various structural applications where high performance and reliability are required, such as in the construction of buildings, bridges, and offshore platforms.

- Q: How is special steel used in the automotive industry?

- Special steel is used in the automotive industry for various applications such as manufacturing engine components, transmission systems, and chassis parts. Its high strength, durability, and resistance to corrosion make it ideal for ensuring the safety, performance, and longevity of vehicles. Additionally, special steel is used in the production of specialized tools and machinery required for automotive manufacturing processes.

Send your message to us

Cold Drawn Hexagonal Steel Bar 4140 5140

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords