Best Aluminum Coil for Coil Coating Aluminium Coils for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

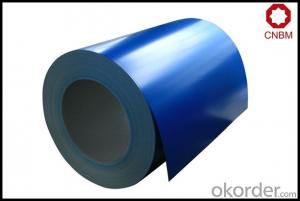

1. Structure of Coil Coating Aluminium Coils for Aluminum Composite Panel Description

• Product: Aluminim coils

• Application:

corrugated roofs, outer walls, ovens, electrically controlled cabinets.

household appliances, transportation, base plate, color coating.

industrial freezers in the residential and industrial buildings.

refrigerator backplane, gas stove, air conditioner, microwave, LCD border.

• Advantage: Full production line with all kinds of coils supply

2. Main Features of the Coil Coating Aluminium Coils for Aluminum Composite Panel

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

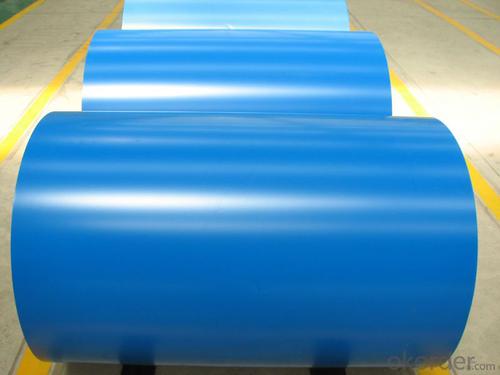

3. Coil Coating Aluminium Coils for Aluminum Composite Panel Images

4. Coil Coating Aluminium Coils for Aluminum Composite Panel Specification

Alloy | AA1050/1100/3003/3005/3105/5005/5052 etc |

Thickness | 0.03mm—4.0mm |

Width | 10mm—1600mm |

Coating | PVDF, PE |

Coatingthickness | Usually16-25 micron, could be 33-40 micron |

Color | According to Ral |

Standard | ASTM-B 209 GB/3008-2006 |

Usage/ApplicationsCoated Aluminum Coil/Sheet | Constructionand decoration, electronic appliances, lighting decoration, air-condition airpipe, sandwich panels and drainage, etc |

5.FAQ of Coil Coating Aluminium Coils for Aluminum Composite Panel

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Yes, aluminum coils can be used for pharmaceutical packaging. Aluminum is a popular choice for pharmaceutical packaging due to its various beneficial properties. It is lightweight, corrosion-resistant, and has excellent barrier properties, making it ideal for protecting pharmaceutical products from external factors such as moisture, oxygen, and light. Aluminum coils can be easily formed into different shapes and sizes, providing versatility for packaging needs. Additionally, aluminum is non-toxic and non-reactive, ensuring the safety and integrity of pharmaceutical products.

- Q: Can aluminum coils be used in curtain wall systems?

- Curtain wall systems can indeed incorporate aluminum coils. The lightweight property, durability, and resistance to corrosion make aluminum a favored material for curtain walls. Shaping and forming aluminum coils is a simple task, enabling the creation of desired profiles for these systems. Moreover, aluminum offers a broad spectrum of colors and finishes, allowing for customization and design adaptability. The utilization of aluminum coils in curtain wall systems also presents energy efficiency advantages, thanks to the commendable thermal conductivity properties of aluminum. In summary, aluminum coils are a fitting and widely employed material for constructing curtain wall systems.

- Q: Related technical standards of aluminium coil

- GB/T 6453-1986 inhalation zirconium aluminum alloy composite stripGB/T 6452-1986 zirconium aluminum alloy powder for inhalationGB/T 3959-1994 industrial anhydrous aluminium chlorideGB/T 3151-1982, water purifying agent, aluminium sulfateGB/T 1871.3-1995 - Determination of aluminium oxide content in phosphorus ores and concentrates -- Volumetric and spectrophotometric methods

- Q: Can aluminum coils be used in refrigeration systems?

- Yes, aluminum coils can be used in refrigeration systems. Aluminum is a popular choice for coil materials in refrigeration systems due to its excellent heat transfer properties and corrosion resistance. Aluminum coils are lightweight, durable, and efficient in transferring heat, making them suitable for use in various refrigeration applications such as air conditioning units, refrigerators, and freezers. Additionally, aluminum coils are easier to shape and install compared to other materials, making them a preferred choice for manufacturers.

- Q: Are aluminum coils suitable for food storage containers?

- Aluminum coils are indeed appropriate for food storage containers. This material is highly favored for such containers because of its many beneficial qualities. To begin with, aluminum is lightweight, which makes it easy to handle and transport. Moreover, it possesses excellent thermal conductivity, allowing for quick heating or cooling, making it perfect for storing both hot and cold food. Additionally, aluminum is resistant to corrosion and does not react with acidic or alkaline foods, ensuring that the taste and quality of the food remain unaffected. Furthermore, aluminum is an environmentally friendly choice as it is sustainable and can be recycled. However, it is worth noting that aluminum containers should be coated with a food-grade lining to prevent any potential interaction between the metal and the food, particularly with acidic foods. In conclusion, aluminum coils are a suitable option for food storage containers due to their lightweight nature, thermal conductivity, resistance to corrosion, and recyclability.

- Q: Is it advisable to purchase and utilize recycled aluminum coils without initial quality assessment?

- <p>No, it is not safe to buy and use recycled aluminum coils without first checking their quality. Recycled aluminum coils may have inconsistencies in thickness, strength, and purity, which can affect the performance and safety of the final product. It's crucial to inspect the coils for any defects, impurities, or deviations from the required specifications to ensure they meet the standards necessary for your application. Quality control is essential to prevent failures, maintain safety, and uphold the integrity of your manufacturing process.</p>

- Q: How are aluminum coils packaged for transportation?

- Aluminum coils are typically packaged for transportation in a way that ensures their safety and prevents damage. The packaging process involves several steps to ensure that the coils are well-protected during handling, storage, and shipping. Firstly, the aluminum coils are usually wrapped in a protective material such as plastic or paper to safeguard them from dust, moisture, and other external factors. This wrapping helps to maintain the quality and integrity of the coils throughout the transportation process. After wrapping, the coils are then placed onto a pallet or wooden skid. This allows for easy handling with forklifts or other machinery during loading and unloading. The coils are securely strapped to the pallet to prevent any movement or shifting during transportation, minimizing the risk of damage. To provide additional protection, the coils may be placed inside a wooden or metal crate. This crate acts as a further barrier against potential impacts or rough handling that may occur during transit. The crates are carefully designed to fit the size and shape of the aluminum coils, ensuring a snug fit and preventing any unnecessary movement. Furthermore, depending on the specific requirements and distance of transportation, the coils may also be packed inside a shipping container. This offers an additional layer of protection against external elements and provides stability during long-distance transportation. Overall, the packaging process for aluminum coils prioritizes their safety and protection during transportation. The use of protective wrapping, pallets, crates, and shipping containers ensures that the coils arrive at their destination in optimal condition, ready for further processing or usage.

- Q: Can aluminum coils be used in extreme weather conditions?

- Yes, aluminum coils can be used in extreme weather conditions. Aluminum is a highly durable and corrosion-resistant material that can withstand harsh weather conditions such as extreme heat, cold, humidity, and even heavy rain or snow. It is frequently used in applications where weather resistance is crucial, such as in air conditioning systems, refrigeration units, and outdoor equipment. Aluminum coils are designed to be strong and reliable, making them suitable for use in extreme weather conditions without compromising their performance or longevity.

- Q: Can a rolling machine be utilized to transform aluminum coils into flat sheets?

- <p>Yes, you can use a rolling machine to roll aluminum coils into sheets. Rolling machines are specifically designed to apply pressure and reduce the thickness of metal coils, such as aluminum, into thinner, flatter sheets. The process involves passing the aluminum coil through the rolling mill, where it is compressed between rollers. This process can be repeated to achieve the desired thickness and flatness of the aluminum sheet. It's important to ensure the rolling machine is suitable for aluminum and that the appropriate settings are used to avoid damaging the material or the machine.</p>

- Q: What is the typical modulus of elasticity for aluminum coils?

- Aluminum coils typically have a modulus of elasticity of approximately 70 GPa (gigapascals) or 10 million psi (pounds per square inch). The modulus of elasticity gauges a material's inflexibility or capacity to withstand distortion under an external force. Aluminum is renowned for its impressive strength-to-weight proportion and remarkable elasticity, rendering it a favored option across diverse sectors such as automotive, aerospace, and construction. Nonetheless, it is noteworthy to acknowledge that the modulus of elasticity may slightly differ depending on the particular alloy and temper of the aluminum coil.

Send your message to us

Best Aluminum Coil for Coil Coating Aluminium Coils for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords