11 3 4 Aluminum Coil for Color Coated Aluminum Coil for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminum Coil

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Color Coated Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

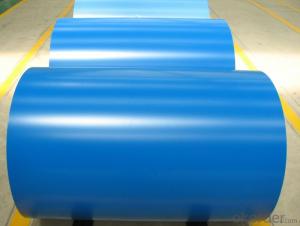

5. Image of Color Coated Aluminum Coil

6. Package and shipping of Color Coated Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is aluminum veneer the same as color coated aluminum coil?

- Aluminum veneer is processed aluminum sheet, while color coated aluminum coil is raw material with color which can be called aluminum veneer after process.

- Q: Can aluminum coils be used for food storage containers?

- Yes, aluminum coils can be used for food storage containers. Aluminum is a safe and commonly used material for food packaging due to its non-toxic, lightweight, and corrosion-resistant properties. It helps to preserve the freshness, flavor, and quality of food while also being recyclable and environmentally friendly.

- Q: Can aluminum coils be used for electrical transmission lines?

- Yes, aluminum coils can be used for electrical transmission lines.

- Q: What are the different color coating options for aluminum coils?

- Customers have a variety of color coating options to choose from for their aluminum coils, depending on their specific needs and preferences. Some commonly used color coating options include: 1. Polyester (PE) Coating: This is a popular choice due to its excellent color retention, durability, and resistance to UV radiation, making it suitable for indoor and outdoor applications. 2. Polyvinylidene Fluoride (PVDF) Coating: PVDF coatings offer superior weather and chemical resistance, as well as color stability. They are highly durable and can withstand harsh environmental conditions, making them suitable for architectural applications. 3. High-Durability Polyester (HDP) Coating: HDP coatings are specially formulated for enhanced durability and resistance to fading, chalking, and abrasion. They are commonly used in demanding applications where long-term color retention and performance are crucial. 4. Silicone Modified Polyester (SMP) Coating: SMP coatings provide good weather resistance, flexibility, and color stability. They are often used in industrial and commercial applications where a balance between performance and cost-effectiveness is required. 5. Polyurethane (PU) Coating: PU coatings offer excellent chemical resistance, flexibility, and adhesion properties. They are commonly used in applications requiring resistance to chemicals, solvents, and harsh weather conditions. In addition, each coating type offers various color options, giving customers a wide range of colors and finishes to choose from. Some manufacturers also offer custom color matching services to meet specific design requirements. It is important to consider factors such as the intended use, environmental conditions, durability requirements, and aesthetic preferences when selecting the appropriate color coating option for aluminum coils. Consulting with a trusted supplier or coating specialist can help determine the most suitable option for a specific application.

- Q: Can aluminum coils be used in architectural mesh applications?

- Aluminum coils have the capability to be utilized in various architectural mesh applications. Widely used in construction and architectural projects, aluminum is a lightweight and adaptable material. It offers numerous advantages for architectural mesh applications, including a high strength-to-weight ratio, resistance to corrosion, and ease of installation. By manipulating aluminum coils, intricate architectural mesh designs can be formed in different shapes and sizes. These coils can be woven, welded, or expanded to produce diverse patterns and textures, granting flexibility in design and customization. Aluminum coil-based architectural mesh applications are present in a wide array of structures such as facades, partitions, ceilings, sunscreens, and safety barriers. The mesh provides benefits such as enhancing aesthetics, ensuring privacy, shading from the sun, enabling ventilation, and even offering security. Not only does aluminum possess aesthetic and functional qualities, but it is also a sustainable choice for architectural mesh applications. It is a highly recyclable material, and its lightweight nature reduces costs associated with transportation and installation, making it an environmentally friendly option. In summary, due to their durability, adaptability, and sustainability, aluminum coils are an exceptional option for architectural mesh applications. Whether it is for commercial, residential, or public spaces, incorporating aluminum mesh can enhance the visual appeal and functionality of architectural designs.

- Q: What is the maximum yield strength of aluminum coils?

- The specific alloy and temper of aluminum significantly influence the maximum yield strength of aluminum coils. Typically, aluminum coils exhibit a yield strength between 10,000 and 40,000 psi. It must be emphasized that diverse properties and, consequently, varying maximum yield strengths are observed in different aluminum alloys and tempers. Furthermore, the thickness and width of aluminum coils have an impact on their maximum yield strength as well. Thus, to ascertain the precise maximum yield strength of aluminum coils, it is advisable to refer to the manufacturer's specifications or standards pertaining to the specific alloy and temper of the coils.

- Q: Explain the distinction between aluminum coil and copper coil, highlighting their properties and uses.

- <p>Aluminum coil and copper coil are both metal coils used in various industries, but they have distinct properties. Aluminum coil is lighter, more corrosion-resistant, and less expensive than copper coil. It is often used in applications where weight and cost are concerns, such as in construction and electrical wiring. Copper coil, on the other hand, has superior electrical conductivity and is more ductile, making it ideal for electrical applications where high conductivity is required, such as in power transmission cables and wiring for electronics. Copper is also used in plumbing due to its resistance to corrosion. In summary, the choice between aluminum and copper coil depends on the specific requirements of the application, including factors like conductivity, weight, cost, and resistance to corrosion.</p>

- Q: Can aluminum coils be used in the production of automotive heat shields?

- Automotive heat shields can indeed utilize aluminum coils. The reason behind aluminum's popularity as a heat shield material lies in its remarkable thermal conductivity and heat resistance characteristics. By utilizing aluminum coils, heat shields can be crafted to be both lightweight and durable, effectively diverting and reflecting heat away from crucial components within the automotive system. Furthermore, the flexibility of aluminum coils enables them to be easily molded and shaped, ensuring a perfect fit for any automotive application.

- Q: Is it possible to utilize aluminum coils in the packaging of food products?

- <p>Yes, aluminum coils can be used for food packaging. They are commonly used in the production of aluminum foil, which is a popular material for food packaging due to its properties such as light weight, barrier to light and oxygen, and recyclability. Aluminum foil is used to wrap food, line baking sheets, and create containers, providing a protective barrier that helps to preserve freshness and extend shelf life. However, it's important to ensure that the aluminum used meets food-grade standards to avoid any health risks.</p>

- Q: Are there any limitations on the length of aluminum coils?

- The length of aluminum coils is indeed constrained by several practical factors. These factors include transportation, handling, and manufacturing capabilities. Transportation presents a significant limitation, as longer coils can be challenging to move efficiently. Loading, unloading, shipping, and logistics become more difficult due to the size and weight of these coils. Specialized equipment may be necessary, which can increase costs and complexity. Handling is another constraint, as longer coils are harder to maneuver and manipulate during production. Larger and more robust machinery may be required, which may not be available or feasible in all manufacturing facilities. Manufacturing capabilities also impose restrictions on coil length. Equipment used for coil production may have size and capacity limitations. Coil processing lines and machinery may have maximum lengths they can handle, and exceeding these limits may not be possible or economically viable. In conclusion, while there is no universal limit on aluminum coil length, practical constraints in transportation, handling, and manufacturing can impose limitations. The specific length of aluminum coils depends on factors such as transportation capabilities, handling feasibility, and manufacturing processes.

Send your message to us

11 3 4 Aluminum Coil for Color Coated Aluminum Coil for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords