Coil Stock Aluminum Prepainted Aluminum Coil for Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Prepainted Aluminum Coil for Composite Panel

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Prepainted Aluminum Coil for Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Prepainted Aluminum Coil for Composite Panel

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

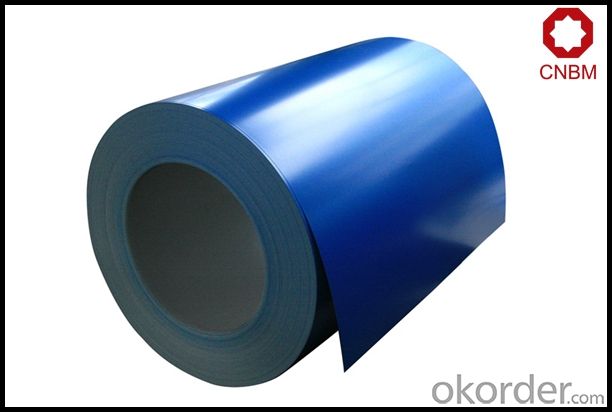

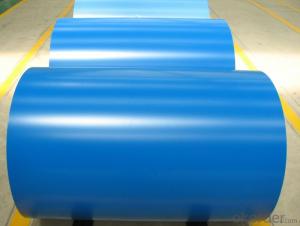

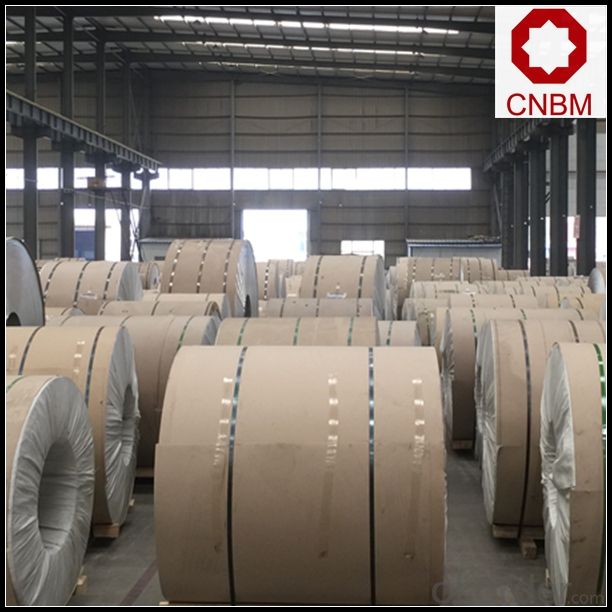

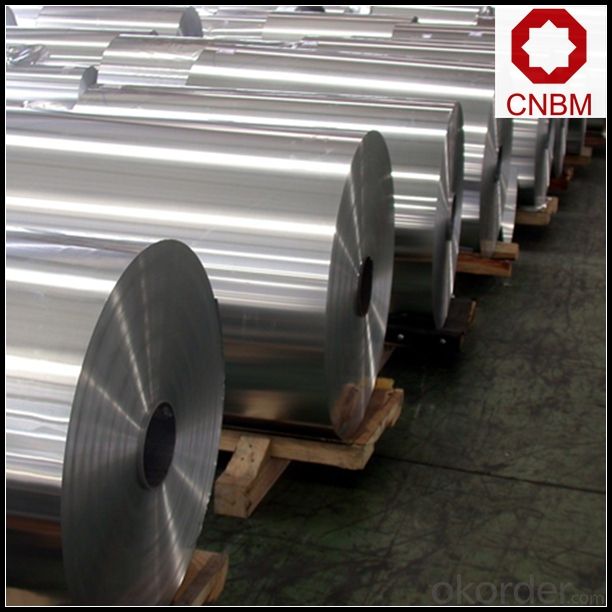

5. Image of Prepainted Aluminum Coil for Composite Panel

6. Package and shipping of Prepainted Aluminum Coil for Composite Panel

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential applications of anodized aluminum coils?

- Anodized aluminum coils have a wide range of potential applications due to their unique characteristics. They are commonly used in architectural and construction projects for cladding, roofing, and facades, as their anodized coating provides excellent durability, corrosion resistance, and aesthetic appeal. Other potential applications include electronic casings, automotive trim, signage, cookware, and industrial components, where the anodized coating offers protection against wear, abrasion, and chemicals. Additionally, the ability to dye the anodized coating enables customization and allows for decorative uses in jewelry, artwork, and consumer goods.

- Q: Can aluminum coils be used in the production of aluminum gutters?

- Yes, aluminum coils can be used in the production of aluminum gutters. Aluminum coils are commonly used in the manufacturing process of aluminum gutters to form the desired shape and dimensions of the gutter system.

- Q: What are the different types of end conditions for aluminum coils?

- Aluminum coils have several types of end conditions, which determine how the ends of the coil are prepared for different applications. Some common end conditions for aluminum coils are as follows: 1. Mill Finish: This is the most basic and widely used end condition for aluminum coils. In mill finish, the coil ends are left untouched after coming off the rolling mill, without any additional processing or finishing. This end condition is suitable for applications where the appearance of the ends is not crucial. 2. Trimmed or Sheared: In this end condition, the coil ends are trimmed or sheared to eliminate any uneven or rough edges. This results in clean and smooth ends, which are often necessary for applications that require precise fitting or appearance. 3. Slit: Slitting refers to cutting an aluminum coil into narrower strips or coils. Slitting is commonly done to customize the width of the coil according to specific requirements. The ends of slit coils can have either mill finish or trimmed ends, depending on the desired application. 4. Recoiled: Recoiling involves rewinding a coil into a smaller or larger coil diameter. This end condition is frequently employed when smaller coils are needed for storage, transportation, or further processing. Recoiling can be done with or without additional trimming or shearing of the ends. 5. Flattened: Flattening is the process of unrolling and flattening the coil to create a sheet or plate. This end condition is often used when the aluminum is intended for further fabrication, such as stamping, forming, or cutting into specific shapes or sizes. The ends of flattened coils are typically trimmed to ensure a clean edge. It is important to note that the specific end condition required for aluminum coils may vary depending on the intended application and customer specifications. Different industries and uses may have unique end condition requirements to ensure optimal performance and appearance of the aluminum coils.

- Q: Can aluminum coils be used in HVAC heat exchangers?

- Yes, aluminum coils can be used in HVAC heat exchangers. Aluminum is a commonly used material in heat exchangers due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. It allows for efficient heat transfer and is often preferred over other materials like copper in certain HVAC applications.

- Q: My grandpa died from Alzheimer’s disease, I didn't know what it was but I came across something slightly disturbing. There were several blog and research sites linking Sodium Aluminum Phosphate ((you know the stuff in bisquick pancake batter stuff or maybe eggo waffles)) what bothered me is that two root words of that ingredient bothers me aluminum Phosphate ((is that like phospherous, as in phospherous paint...didn't that turn out bad to the body?)) If so maybe I need a second opinion or ensurance that it is real or not if it is I'm not eating pancakes again. Please help answer this.

- Sodium Aluminum Phosphate

- Q: What are the common surface preparation methods for aluminum coils?

- The common surface preparation methods for aluminum coils include cleaning, degreasing, etching, and conversion coating.

- Q: On Square-D service panels, are the main lugs rated for aluminum wire? Or do I need to use an anti-oxidant compound? What about on Milbank outdoor meter bases?

- No you do not have to use any type compound on it.

- Q: how tall is a crushed aluminium soda can compared to a non crushed one.i need measurements in centimeters please.ALSO!! AN IMAGE that actually has both of the two with the measurements would be SUPER HELPFUL

- I don't understand why you can't just measure a can, then crush it and measure it again. And with the number of cellphones kids have today, every one can take a picture. Why do we need to do this for you?

- Q: Can aluminum coils be used in aerospace applications?

- Yes, aluminum coils can be used in aerospace applications. Aluminum is a widely used material in the aerospace industry due to its lightweight and high strength-to-weight ratio. Aluminum coils are often used in the construction of aircraft structures, such as fuselages, wings, and landing gear, as well as in heat transfer and cooling systems. Their excellent corrosion resistance and high thermal conductivity make them suitable for various aerospace applications. Additionally, aluminum coils can be easily formed and fabricated, allowing for complex shapes and designs required in aerospace components.

- Q: Can aluminum coils be used in marine applications?

- Marine applications can indeed utilize aluminum coils. The popularity of aluminum in this field can be attributed to its remarkable resistance to corrosion, lightweight nature, and impressive strength-to-weight ratio. Boats, ships, and other marine structures are commonly constructed using aluminum due to these advantages. Specifically, aluminum coils are especially valuable in marine applications because they can be easily shaped and sized to fit different marine industry parts and components. Moreover, these coils possess the ability to endure harsh marine environments and exhibit exceptional resistance to corrosion caused by saltwater, a major concern in marine applications. All in all, the utilization of aluminum coils in marine applications is a dependable and efficient choice.

Send your message to us

Coil Stock Aluminum Prepainted Aluminum Coil for Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords