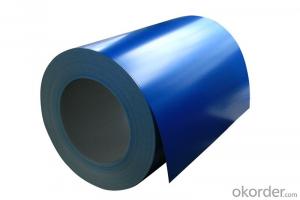

PE Coated Aluminum Coil for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 1 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

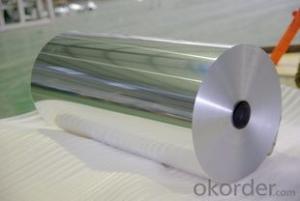

1. Structure of Aluminium Foil Description:

Aluminium Foil is structured by aluminium paper, which is the raw material .It is suitable for: Tobacco, food, beer, beverage, decoration, electric cable, electrolytic capacitor, medicine and air-conditioner.

2. Main Features of the Aluminium Foil:

High heat reflection & low thermal conductivity

Heat preservation & energy saving

Moisture barrier & waterproof

Low flammability

Strong, durable & corrosion resistance

Light weight & easy to install

Clean, safe and fibre free & no odour and toxicity, totally environmental-friendly

No mildew growth & no rodent and insect nesting

3. Aluminium Foil Images

4. Aluminium Foil Specification

01) Alloy: A3003 A1100 A8011 A1050etc

02) Aluminum thickness: 0.024mm~0.80mm

03) Aluminum max width:1600mm

Standard width: 1240mm

Special width such as 1300mm, 1520mm, 1570mm, are also available

04) Coil's standard diameter: 1200mm

Interior diameter:150mm,405mm or 505mm

05) weight: 2.5T/coil 3.0 T/coil

06) Coating finish: PVDF, POLYESTER, ACRYLIC

07) Gloss: meet the customer requirement

08) Total coating thickness:

PVDF coating: more than 25 micron

Polyester coating: more than 18 micron

09) Coating hardness (pencil hardness) more than 2H

10) coating adhesive : no lower than first grade

11) Impact resistance: No cracking and peeling (50kg/cm ,ASTMD-2794:1993)

12) Flexibility (T-bend): 2T

13) MEK resistance: more than 100

14) Bottom side aluminum sheet is coated with protective polyester material, thickness more than 6 micron

15) outer packing ;export standard , wooden plate .

Applications:

Used to manufacture decorative materials, such as aluminum veneers, aluminum plastic panels, perforated panels, and clean plates, etc:

1) Exterior applications: wall cladding, facades, roofs and canopies, tunnels, column covers or renovations

2) Interior applications: wall cladding, ceilings, bathrooms, kitchens and balconies

3) Advertisement and market applications: display platforms

signboards, fascias and shop fronts

4) Transport and industrial applications

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Aluminum foil waterproof material, how much does it cost for a square?

- It depends on whether you are using SBS waterproof membrane or self-adhesive waterproof coiled material

- Q: The aluminium foil is melted and glued to the electric ceramic stove. How can I get rid of it? A safe way of not hurting the stove

- The panel of the induction cooker is a microcrystalline board. The hardness is higher than that of aluminum. It can be easily picked off with a knife.

- Q: How to improve the cleaning effect of aluminum foil

- The ice bag is fashionable and beautiful in appearance and fashionable in style. The bag is easy to clean and can be folded and stored conveniently. The product also has the function of heat preservation, and is also suitable for winter heat preservation. It is essential for life, travel and leisure.

- Q: Home water heater exhaust pipe insulation material need to wrap it, please can Naiduo high temperature aluminum foil? Can you meet the requirements?

- The melting point of aluminium is 660.4 degrees centigrade and the boiling point is 2467. The foil can resist high temperature, but it will be oxidized. A white powder, a covalent compound, having a melting point of 2050 DEG C and a boiling point of 3000 DEG C. Therefore, it can be inferred that if oxidized, the final result may not be aluminum foil, but also alumina. A touch may be powdery.

- Q: Can foil be used to shield electromagnetic interference? Please, great God!

- The aluminum foil tape that the air conditioning pipe is winding is quite good, you can try

- Q: Is the aluminum foil used for fresh keeping the better the heat preservation?

- It consists of low density polyethylene, which is physically foamed and produces numerous independent bubbles.

- Q: Can foil paper be used in a microwave oven with barbecue?

- This one thing but to free 130 yuan for the security, if not only need to pay 130 yuan plus overhaul costs 35 yuan, because the scope for large to overhaul.

- Q: The difference between pure aluminium foil bags and aluminium plated bags

- Three, from the performance point of view, pure aluminum bags moistureproof, cooling effect better than aluminum bag, pure aluminum bag completely avoid light, aluminized bag is shading effect.Four, from the use, the pure aluminum bag is more suitable for vacuum pumping, such as food, meat and other products, while the aluminum plated bag suitable for tea, powder, electronic and other pieces.Five, the inside of the bag facing the light or sunlight, can see through the bag of light is plated aluminum foil, invisible is pure aluminum foil

- Q: Can aluminum foil be harmful to human body?

- Laden with foodIt's very common to use aluminum foil trays to carry food, although the foil tray is disposable, but the ingredients are aluminum, which is less harmful to nature. barbecueSome foods (such as sweet potato, Enoki mushroom etc.) must be wrapped with aluminum foil to avoid burning, burning. With foil wrapped to cook seafood, Enoki mushroom, can retain the flavor.

- Q: Clamp aluminum foil paper with sticky?

- ChinaIncluding the heart ballMain ingredients: 750 grams eel, pork (thin) 200 grams, kilogramShrimp accessories: letinous edodes (fresh) 50 grams, pork (hair) 50 grams, 200 grams of sweet potato powder,Spices: soy sauce 10 grams, 5 grams of salt, monosodium glutamate 3 grams, sesame oil 10 grams, 3 grams of pepper, onion 10 grams

Send your message to us

PE Coated Aluminum Coil for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 1 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords