Billet Aluminum Coil Spacers for Metallic Coated Aluminum Coils Used in Aluminum Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

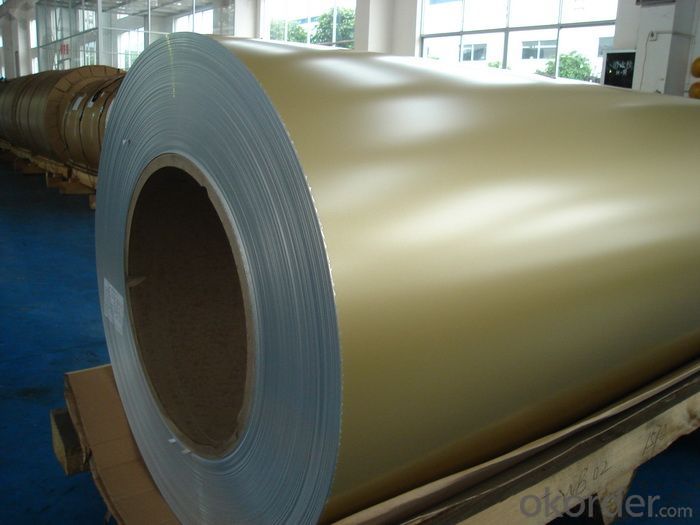

1. Structure of Metallic Coated Aluminium Coils Used for Aluminium Composite Panels

Metallic coated aluminium coils are processed through t roller coating and baking with precise polyester paints.

Its color is glossy and with variety colors. Chromatic aberration is small, impact resistance is strong and easy to be processed, and all its performance has reached or surpassed the national criteria. The products are widely used in indoor and door decoration, ceilings, room surface tiles, corrugated boards, wall panels, advertisement boards, counters, home appliances, decoration in and out of autos and boats.

2. Main Features of Metallic Coated Aluminium Coils Used for Aluminium Composite Panels

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

3. Metallic Coated Aluminium Coils Used for Aluminium Composite Panels Images

4. Specification of Metallic Coated Aluminium Coils Used for Aluminium Composite Panels

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What causes tower after cutting aluminum coil

- Insulation aluminum coil will appear when the cooling bending phenomenon, reason is generally under the conditions of air cooling, the heat transfer coefficient of the aluminum coil insulation parts in contact with the air were flat, but because the wall thickness or different shapes, different parts of the heat dissipation rate is not balanced, resulting in thick wall or hollow tube heat faster than the thin Department of slow, resulting in insulating aluminum roll cooling occurs to the hollow part.

- Q: Can aluminum coils be used in electrical transformers?

- Yes, aluminum coils can be used in electrical transformers. While copper is the most commonly used material for transformer windings, aluminum has also been increasingly used due to its cost-effectiveness and lighter weight. Aluminum coils are typically used in distribution transformers, which are smaller in size and operate at lower voltages. However, there are certain considerations to bear in mind when using aluminum coils in transformers. Aluminum has a lower conductivity than copper, so the aluminum coils need to have larger cross-sectional areas to compensate for this. Additionally, aluminum has a higher coefficient of thermal expansion than copper, so proper precautions must be taken to account for the differential thermal expansion between the aluminum windings and other transformer components. Overall, aluminum coils can be a suitable choice for specific transformer applications, but the design and manufacturing process must be carefully executed to ensure optimal performance and reliability.

- Q: What are the common recycling methods for aluminum coils?

- Aluminum coils can be recycled using various methods. Mechanical recycling is a commonly employed technique. It entails shredding the coils into small pieces and then melting them to create new coils. This method is both efficient and cost-effective, as it maintains the quality of the aluminum material while allowing for its reuse. Pyrolysis is another method used for aluminum coil recycling. It involves heating the coils at high temperatures in the absence of oxygen. This process breaks down the aluminum into its constituent elements, enabling the recovery of valuable metals and other byproducts. Chemical recycling is an alternative approach for recycling aluminum coils. It involves dissolving the coils in a chemical solution to separate the aluminum from other materials. The resulting aluminum can then be utilized to manufacture new coils. Lastly, smelting is a method that can be employed for aluminum coil recycling. It revolves around melting the coils and separating impurities through electrolysis. This method facilitates the recovery of pure aluminum, which can be utilized in the production of new coils. In summary, these recycling methods play a pivotal role in reducing the environmental impact of aluminum coil production. They conserve resources, minimize waste, and promote the sustainability of the aluminum industry by encouraging the reuse of materials and decreasing the need for new aluminum production.

- Q: How are aluminum coils joined together?

- Aluminum coils are typically joined together through a process called welding. This involves heating the ends of the coils and applying pressure to fuse them together, creating a strong and seamless joint.

- Q: Are aluminum coils resistant to oil and grease?

- Yes, aluminum coils are generally resistant to oil and grease.

- Q: Who knows about how much money can be sold in a three metre high similar aluminum door?

- How wide is it, mainly to see the door you have multiple components, scrap is generally about 10 yuan a kilogram!

- Q: How does the gauge of aluminum coils affect their performance?

- The gauge of aluminum coils refers to the thickness of the aluminum sheet used to manufacture the coil. The gauge is typically measured in terms of its thickness, with a smaller gauge indicating a thicker sheet. The gauge of aluminum coils has a significant impact on their performance. Firstly, the gauge affects the strength and durability of the aluminum coil. Thicker gauges provide increased strength and resistance to bending or warping, making them suitable for applications that require robust and long-lasting coils. On the other hand, thinner gauges are more flexible but may be prone to damage or deformation, making them suitable for less demanding applications. Secondly, the gauge affects the thermal conductivity of the aluminum coil. Thicker gauges have lower thermal conductivity, meaning they are slower to heat up or cool down. This can be advantageous in certain applications where temperature control is crucial, as it helps to maintain a stable environment. Thinner gauges, on the other hand, have higher thermal conductivity, allowing for faster heat transfer. This can be beneficial in applications that require rapid heating or cooling. Thirdly, the gauge affects the weight and cost of the aluminum coil. Thicker gauges are heavier and generally more expensive due to the increased amount of material used. This can be a consideration in applications where weight or cost is a significant factor. Thinner gauges, being lighter and less expensive, can be more suitable for applications where weight reduction or cost efficiency is important. Lastly, the gauge affects the ease of fabrication and formability of the aluminum coil. Thinner gauges are more easily bent, shaped, or formed into desired configurations, making them suitable for applications that require intricate or complex designs. Thicker gauges, while less malleable, can still be formed but may require specialized equipment or processes. In conclusion, the gauge of aluminum coils has a direct impact on their performance. It affects their strength, durability, thermal conductivity, weight, cost, and formability. Therefore, selecting the appropriate gauge for a specific application is essential to ensure optimal performance and efficiency.

- Q: Does anyone know of any men's deodorant that doesn't contain aluminum? It has to be strong, as I do sweat a lot.

- Deodorants Without Aluminum For Men

- Q: Can aluminum coils be used in the production of electrical transformers?

- Yes, aluminum coils can be used in the production of electrical transformers. Aluminum coils offer several advantages such as being lighter in weight, having better thermal conductivity, and being more cost-effective compared to traditional copper coils.

- Q: What are the fire-resistant properties of aluminum coils?

- Due to its inherent characteristics as a metal, aluminum exhibits excellent fire-resistant qualities when formed into coils. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum can endure high temperatures without melting, thereby making aluminum coils resistant to fire hazards. Furthermore, unlike certain other metals, aluminum does not produce flammable gases when exposed to fire. This non-combustible attribute prevents the fire from spreading and minimizes the potential for fire-related damages. Additionally, due to its low thermal conductivity, aluminum does not efficiently conduct heat. Consequently, aluminum coils do not facilitate the transfer of heat from one area to another, which aids in containing and controlling the fire's spread. Moreover, aluminum coils frequently undergo a protective coating process to enhance their fire resistance. These coatings, composed of materials like polyvinylidene fluoride (PVDF) or polyester, create an additional barrier against fire and heat. Engineered to withstand extreme temperatures while maintaining their integrity, these coatings further bolster the fire-resistant qualities of aluminum coils. In summary, aluminum coils possess exceptional fire-resistant characteristics owing to their high melting point, non-combustible nature, low thermal conductivity, and protective coatings. These attributes make aluminum coils a dependable choice for applications where fire safety is paramount, such as in building construction, electrical wiring, and transportation industries.

Send your message to us

Billet Aluminum Coil Spacers for Metallic Coated Aluminum Coils Used in Aluminum Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords