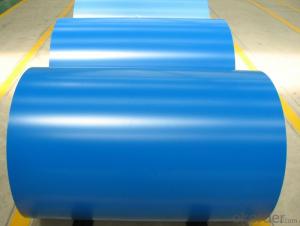

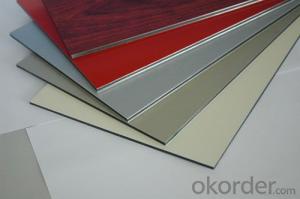

Aluminum Color Coil Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

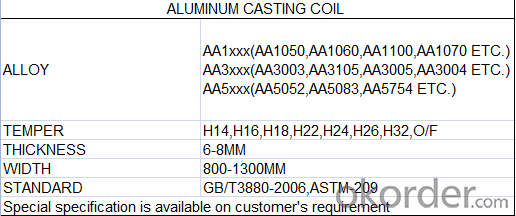

1.Structure of Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. The thickness of Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

4. Production Process of Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: Are aluminum coils suitable for high-strength applications?

- In comparison to materials like steel, aluminum coils generally have a lower tensile strength, making them unsuitable for high-strength applications. Additionally, aluminum is more susceptible to deformation when exposed to heavy loads due to its lower strength-to-weight ratio. Nonetheless, there are certain aluminum alloys like the 7000 series that have been developed to increase their strength, making them suitable for industries like aerospace and automotive that prioritize lightweight properties and moderate strength. However, when it comes to applications that demand the highest level of strength, steel or other high-strength materials are typically preferred over aluminum coils.

- Q: The user is asking if there are any recycling programs specifically for aluminum coil in their country.

- <p>Yes, many countries have recycling programs for aluminum coil. These programs aim to collect and recycle aluminum coils to reduce waste and conserve resources. The availability and specifics of these programs can vary by country, so it's best to check with local waste management authorities or recycling centers for information on programs in your area. Some countries also have legislation mandating recycling of certain materials, including aluminum, to encourage participation and reduce environmental impact.</p>

- Q: What unique considerations or precautions need to be taken when handling aluminum coils?

- <p>When handling aluminum coils, there are several special requirements to consider. First, it's crucial to handle the coils carefully to avoid denting or scratching the surface, which can affect their quality and value. Secondly, due to aluminum's lightweight and high strength, specialized equipment like slitters and rewinders may be necessary to process the coils. Additionally, it's important to store aluminum coils in a dry environment to prevent corrosion. Proper ventilation is also required to avoid condensation, which can lead to oxidation. Finally, safety measures such as wearing protective gear and following material handling guidelines are essential to prevent accidents and injuries.</p>

- Q: Explain how aluminum coils impact transportation, including considerations for logistics and safety.

- <p>Aluminum coils significantly affect transportation due to their weight and size. They are heavy and bulky, which requires specialized vehicles for transportation to ensure stability and prevent damage. The weight of aluminum coils can impact fuel efficiency and may require more powerful vehicles, increasing fuel consumption and emissions. Additionally, the transportation of aluminum coils must adhere to strict safety regulations to prevent accidents, especially when transported over long distances or on public roads. This can involve securing the load properly, using appropriate transport methods, and ensuring drivers are trained to handle heavy loads. The logistics of transporting aluminum coils can be complex, requiring careful planning and coordination to minimize delays and costs.</p>

- Q: Why are the aluminum coils sticky after annealing?

- There is oil or the annealing time is too long!

- Q: Is it possible to utilize aluminum coil in the welding process?

- <p>Yes, aluminum coil can be used for welding. It is commonly used as a filler material in processes like MIG (Metal Inert Gas) welding, where it is fed continuously into the weld pool to create a joint. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need to prevent oxidation. The aluminum coil must be of high quality and clean to ensure a strong, corrosion-resistant weld.</p>

- Q: How are aluminum coils protected against galvanic corrosion?

- To protect aluminum coils from galvanic corrosion, a combination of surface treatments and protective coatings is employed. An effective method involves applying anodization, which entails treating the aluminum with an acid solution through electrolysis. This process forms a protective oxide layer on the surface, acting as a barrier against direct contact with other metals that could cause galvanic corrosion. Alternatively, a protective coating such as a polymer or paint can be used on the aluminum coils. These coatings create a physical barrier, shielding the metal from corrosive elements in the environment. Careful consideration is given to selecting coatings that adhere well to the aluminum surface and exhibit excellent resistance to corrosion. Aside from surface treatments and coatings, proper design and material selection are crucial in safeguarding aluminum coils against galvanic corrosion. Avoiding direct contact between dissimilar metals and opting for compatible materials helps minimize the risk of corrosion. Isolation materials, such as gaskets or insulating tapes, can be utilized to separate the aluminum coil from other metals in contact. Regular maintenance and cleaning also contribute to protection against galvanic corrosion. It is essential to regularly remove accumulated dirt, debris, and corrosive substances from the aluminum coils to prevent the formation of localized corrosion cells. In conclusion, a combination of surface treatments, protective coatings, proper design, and regular maintenance is vital in preserving the longevity and performance of aluminum coils in various applications.

- Q: What are the typical mechanical properties of aluminum coils?

- The mechanical properties of aluminum coils can vary depending on the specific alloy and temper of the material. However, some typical mechanical properties of aluminum coils include: 1. Tensile strength: Aluminum coils generally have a high tensile strength, which refers to the maximum amount of tensile stress a material can withstand before it breaks. This property is important for applications that require the material to withstand heavy loads or stress. 2. Yield strength: Yield strength is the amount of stress a material can withstand without permanently deforming. Aluminum coils typically have a relatively high yield strength, allowing them to maintain their shape and structural integrity under normal operating conditions. 3. Elongation: Elongation refers to the amount a material can stretch or deform before it fractures. Aluminum coils typically have a relatively high elongation, making them suitable for applications that require the material to be formed or bent without breaking. 4. Hardness: The hardness of aluminum coils can vary depending on the alloy and temper. Aluminum alloys can be heat-treated to increase their hardness, making them more suitable for applications that require wear resistance or need to withstand harsh environments. 5. Fatigue strength: Fatigue strength is the ability of a material to resist the formation and growth of cracks under cyclic loading conditions. Aluminum coils generally exhibit good fatigue strength, making them suitable for applications subjected to repeated or fluctuating loads. It is important to note that these properties can vary depending on the specific alloy, temper, and processing conditions of the aluminum coils. Therefore, it is recommended to consult the material specifications or contact the manufacturer for more accurate and detailed information on the mechanical properties of specific aluminum coils.

- Q: helicopters rotorblades are made of honeycombed aluminum to give them strength, so isn't it a good idea for automakers to use the same technology to strengthen the frames of autos to make them lesslikely to cave in during a side impact auto accident?

- Honeycombed materials are not strong in all directions. Honeycombed materials are strong in a force at 0 degrees, but will collapse under a teensy force at 90 degrees. Since a car can be damaged from many directions, the use of honeycombed materials would not be ideal. The website I've listed is about the strength of honeycombed materials and is interesting, but does not specifically address your question.

- Q: What are the different coil winding methods for aluminum coils?

- There are several coil winding methods for aluminum coils, including hand winding, machine winding, and automated winding. Hand winding is a manual process where the wire is carefully wrapped around the coil by hand. Machine winding involves using a winding machine that automatically wraps the wire around the coil, increasing efficiency and accuracy. Automated winding takes it a step further by utilizing robotic arms or other automated systems to wind the coils, providing even greater precision and speed.

Send your message to us

Aluminum Color Coil Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords