Flat Aluminum Coil - Hot Rolled Aluminium Strip in Coils AA1050-F

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

2. Main features of the product

a.Competitive price---We have our own aluminium mills, and we can provide competitive price than other small suppliers.

b.Professional after-sale service---We have more than 20 years exportation experience. So you do not worry about the after-sales service.

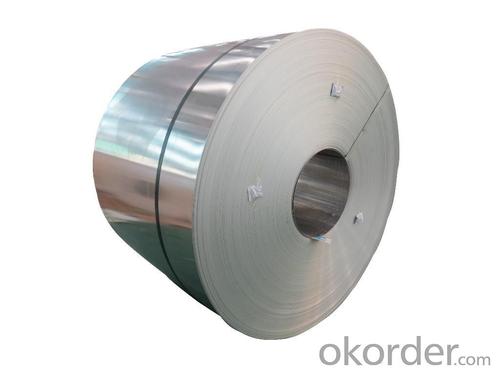

3. Image 4. Product Specification

c.Fast delivery time---Our usual delivery time is about 30 days.

Alloy Temper Thickness Coil ID Coil Weight AA1050 F 3-8mm 610mm Min 5 tons

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum coils suitable for outdoor signage and displays?

- Yes, aluminum coils are suitable for outdoor signage and displays. Aluminum is a highly durable and weather-resistant material, making it an excellent choice for outdoor applications. It is known for its ability to withstand extreme temperature variations, UV rays, moisture, and corrosion. Aluminum coils are lightweight, yet strong, which makes them easy to handle and install. They are also versatile and can be easily shaped and formed into various sizes and designs. In addition, aluminum has excellent printability, allowing for vibrant and long-lasting graphics. Overall, aluminum coils provide a reliable and cost-effective solution for outdoor signage and displays.

- Q: Can aluminum coils be utilized to create jewelry boxes and other decorative objects?

- <p>Yes, aluminum coils can be used to make jewelry boxes and other decorative items. Aluminum is lightweight, durable, and has a shiny finish that can add a touch of elegance to decorative pieces. It can be easily shaped and manipulated using various tools and techniques, such as bending, cutting, and engraving. Additionally, aluminum's resistance to corrosion makes it a practical choice for long-lasting decorative items. However, it's important to consider that working with aluminum may require specific skills and tools, and the final appearance can be influenced by the quality of the aluminum and the craftsmanship involved.</p>

- Q: if the resistivity of aluminium is 2.7×10-8 Ωm

- Let ρ be the resistivity of the aluminum cable, A the cross sectional area of the cable and l the cable's length. The resistance R of the aluminum cable is now given by: R = ρ·l / A = 2.7·10^-8·(10·10^3) / (π·r?) = 2.7·10^-8·(10·10^3) / (π·(1·10^-3)?) = 85.9 Ω I guess the tricky part is remembering: R = ρ·l / A but when you realize how intuitive this equation is you don't have to memorize it. The resistance R is proportional to the resistivity ρ, so we must have the following in our equation: R = ρ·k , where k is some value governed by the dimensions of the cable! It is logical that the resistance is also proportional to the wires length l. This is logical when you realize that the longer the wire the more obstacles the electrons will have to pass by! Now we have that: R = ρ·l·c , where c is another value governed now by the cross sectional area (only dimensional property left). If we think of the wire as a highway with cars instead of electrons we realize that there is less resistance (higher speed) when the highway has many lanes and is very broad. From this we realize that the greater the cross sectional area the smaller the resistance. R must therefore be inversely proportional to A. We now have: R = ρ·l / A I hope there are no mistakes here :P

- Q: What is the primary function or use of a spring steel wire coil?

- <p>A spring steel wire coil is primarily used for its high elasticity and strength. It is designed to return to its original shape after being deformed, which makes it ideal for applications requiring resilience and durability. Common uses include the manufacturing of various types of springs, such as compression springs, torsion springs, and extension springs, found in automotive suspensions, mechanical devices, and industrial equipment. The coil's properties also make it suitable for applications in furniture, electronics, and other industries where a reliable and consistent force is needed.</p>

- Q: Never put oil in the water. Oil keeps the pasta from absorbing the sauce. Also add a little of the pasta water 3 Tbs. to the sauce. This helps sauce to adhere to pasta. The best remedy for pasta sticking. Use an aluminum stock pot. (tall pan). I don't know why but this works. I have using this stock pot for pasta for 40 years. I've tried stainless, non-stick, etc. they all stick. Except for the Aluminum.1 lb. of pasta, 4 qts. of water. 1Tbs. saltTurn burner to high,keep it therebring to boil then boil for 3 minutes, add 1 TBS salt, add pasta. Stir slowly 2 minutes, until the water boils. Cook tender enough for a fork to cut through but still a little firm

- cool tip. thanks.

- Q: Are aluminum coils suitable for heat sinks?

- Yes, aluminum coils are suitable for heat sinks. Aluminum is a lightweight, highly conductive material that efficiently transfers heat away from electronic components. Its excellent thermal conductivity and corrosion resistance make it a popular choice for heat sink applications.

- Q: What types of aluminum coil are best suited for specific applications?

- <p>Yes, different types of aluminum coil are better suited for specific applications. For instance, 1100 series aluminum coil, known for its high purity and excellent formability, is ideal for applications requiring deep drawing or bending. The 3003 series is often used for applications needing good corrosion resistance and formability, such as automotive parts and chemical equipment. The 5052 series offers a balance of strength and corrosion resistance, making it suitable for marine applications and aircraft structures. The 6061 series is known for its strength and is often used in construction and transportation industries. Each series has unique properties that make it more suitable for certain applications, so selection should be based on the specific requirements of the project.</p>

- Q: Is it possible to use a welding process to join two pieces of aluminum coil?

- <p>Yes, you can weld two pieces of aluminum coil together, but it requires specific techniques and equipment. Aluminum welding is different from steel welding and requires a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process. It's crucial to use a clean, dry aluminum filler rod and maintain a clean, oxide-free surface on the aluminum. Additionally, a shielding gas like argon is necessary to protect the weld area from oxidation. Special precautions must be taken due to aluminum's high thermal conductivity and reactivity, so it's recommended to have experience or professional guidance when welding aluminum.</p>

- Q: What are the different types of aluminum coils?

- There are several different types of aluminum coils, including plain aluminum coils, painted aluminum coils, embossed aluminum coils, and coated aluminum coils. Each type has specific properties and uses, making them suitable for different applications in various industries.

- Q: What are the potential applications of pre-painted aluminum coils?

- Pre-painted aluminum coils have a wide range of potential applications due to their versatility and durability. One potential application is in the construction industry, where pre-painted aluminum coils can be used for roofing and cladding. The pre-painted coating provides an attractive and protective finish, making it ideal for both residential and commercial buildings. Additionally, aluminum is lightweight, which makes it easier to install and transport. Another potential application is in the manufacturing of appliances and electronics. Pre-painted aluminum coils can be used to create outer casings for various appliances, such as refrigerators, ovens, and air conditioners. The coating provides a smooth and aesthetically pleasing finish, while the aluminum itself offers excellent heat dissipation properties. Pre-painted aluminum coils also find applications in the automotive industry. The durable coating helps protect the surface of the vehicle from scratches, UV rays, and corrosion. Additionally, aluminum is lightweight, which can contribute to fuel efficiency and improved performance. In the signage industry, pre-painted aluminum coils are commonly used for outdoor and indoor signage. The coating provides a long-lasting and vibrant finish, making it suitable for a variety of signage applications, such as billboards, store signs, and traffic signs. Furthermore, pre-painted aluminum coils can be employed in the manufacturing of furniture and fixtures. The coating adds a decorative touch to furniture pieces, while the aluminum provides strength and stability. This makes pre-painted aluminum coils suitable for items such as cabinets, shelves, and decorative panels. Overall, the potential applications of pre-painted aluminum coils are vast and diverse. Their versatility, durability, and attractive finish make them suitable for various industries, including construction, manufacturing, automotive, signage, and furniture.

Send your message to us

Flat Aluminum Coil - Hot Rolled Aluminium Strip in Coils AA1050-F

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords