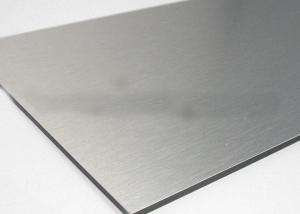

Brushed Aluminum Coil Sheet for Composite Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description of Painted Aluminium Coil Sheet for Composite Panel

Alloy: 1050, 1100, 3003, 3005, 3105, etc

Thickness: 0.15mm~1mm

Painting Thickness: 5-10mic for back coating, 15-40mic for top coating

Paint Types: PVDF, PE, HDPE, LDPE, etc

Width: 900mm- 1950mm

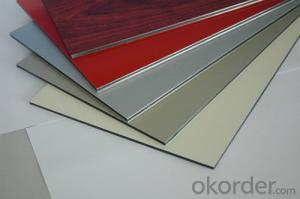

Color: According to RAL colors or customer's samples

2. Application of Painted Aluminium Coil Sheet for Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Painted Aluminium Coil Sheet for Composite Panel

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Painted Aluminium Coil Sheet for Composite Panel

6. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: What substances are used to make aluminum coils?

- <p>Aluminum coils are made from aluminum, a lightweight and malleable metal with the chemical symbol Al. They are typically produced from high-purity aluminum or aluminum alloys, which may include small amounts of other elements to enhance specific properties such as strength, durability, or resistance to corrosion. Pure aluminum is soft and lacks strength, so alloys are often used to improve these characteristics for various applications.</p>

- Q: Which is better - a steel roof or an aluminum roof?

- Steel

- Q: Are aluminum coils suitable for high-strength applications?

- Aluminum coils are generally not suitable for high-strength applications due to their relatively low tensile strength compared to other materials such as steel. Aluminum has a lower strength-to-weight ratio and is more prone to deformation under high loads. However, there are specific alloys of aluminum that have been developed to enhance their strength, such as the 7000 series aluminum alloys, which can offer higher strength levels. These alloys are commonly used in aerospace and automotive industries for their lightweight properties and moderate strength. Nevertheless, for applications requiring the utmost strength, steel or other high-strength materials are usually preferred over aluminum coils.

- Q: im taking avelox antibiotic for my thorat bacterial infection....i brought guava juice today but i think it contains magnesium or aluminum....how long after taking avelox can i drink the guava juice????

- call a pharmacist

- Q: I am so confused right know. I want to cook something using an aluminium foil. Is the reflective side supposed to be inside or outside?

- not usually too big a deal either way really, but make absolutely sure you NEVER use it in a microwave as bill suggested!!!

- Q: Is it possible to utilize an angle grinder for cutting hot rolled aluminum coils?

- <p>Yes, you can use an angle grinder to cut hot rolled aluminum coils, but you must take precautions. Use a grinding disc specifically designed for metal cutting, preferably one with a diamond or carbide grit for better performance on aluminum. Ensure the grinder is equipped with a safety guard and wear appropriate safety gear, including goggles and gloves. Be aware that aluminum can be reactive when heated, so cutting may produce sparks and fumes; ensure proper ventilation. Always follow the manufacturer's guidelines for your specific angle grinder and safety regulations.</p>

- Q: The export of aluminum coil, according to steel coil declaration, will there be any problems?

- If you have already declared itCheck the corresponding HS code, to import countries taxes and fees are the same, whether the customer side mind?.China's tax rebate rate, you also see what kind of high?.In addition to export will have a steel coil sampling, aluminum volume difference is relatively large, so if the declaration, to take note of this, if the sampling try with conversational communication forwarding, otherwise it would be a big problem.

- Q: How many companies have used aluminum coil?

- Too many. All the companies who make the aluminum products you have seen in daily life have used it. So it is hard to explain.

- Q: Can aluminum coils be embossed or textured?

- Aluminum coils possess the capability to undergo embossing or texturing, thereby enabling the creation of patterns or designs on their surface. This can be achieved through mechanical or chemical processes. The resulting embossed or textured surface not only enhances the visual appeal but also improves the functionality of the aluminum coil, by augmenting its grip or minimizing glare. Consequently, these aluminum coils, with their embossed or textured features, have found widespread utilization across industries like construction, automotive, and packaging.

- Q: Are aluminum coils suitable for decorative purposes?

- Yes, aluminum coils are suitable for decorative purposes. They are lightweight, durable, and can be easily shaped and colored to create various decorative elements such as trim, edging, and accents. Additionally, aluminum coils are resistant to corrosion, making them ideal for both indoor and outdoor decorative applications.

Send your message to us

Brushed Aluminum Coil Sheet for Composite Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords