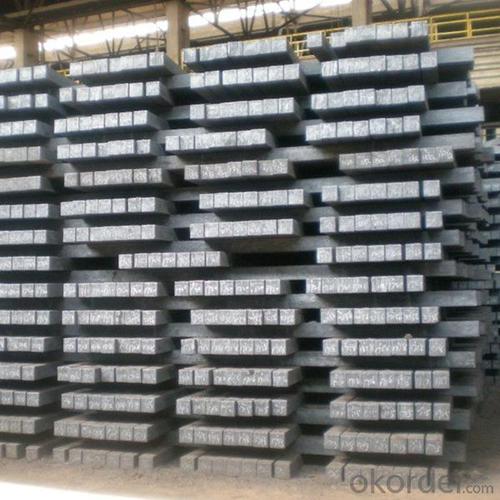

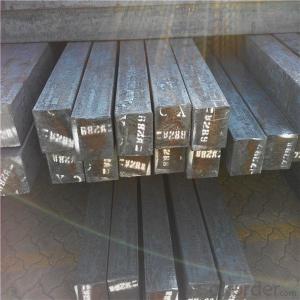

chrome alloy square mild steel billets prime billet steel for building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

square steel billets

Specifications of square steel billets

100 X 100

125 X 125

150 X 150

Physical Properties:

Description | As per IS 2830 | Shyam Billets |

Bend (max.) | 5 mm per meter | >= 5 mm per meter |

Carbon (max.) | 3mm per meter | >= 3 mm per meter |

Length | 3 mt - 13 mt | 3 mt - 9 mt |

Chemical Properties:

Ladle Analysis: | ||

Designation | Carbon | Manganese |

C15 | 0.12-0.18 | 0.30-0.60 |

C18 | 0.15-0.21 | 0.30-0.60 |

C20 | 0.17-0.23 | 0.30-0.60 |

C15 MMn | 0.12-0.18 | 0.60-1.00 |

C18 MMn | 0.15-0.21 | 0.60-1.00 |

C20 MMn | 0.17-0.23 | 0.60-1.00 |

C15 HMn | 0.12-0.18 | 1.00-1.50 |

C18 HMn | 0.15-0.21 | 1.00-1.50 |

C20 HMn | 0.17-0.23 | 1.00-1.50 |

Chemical Analysis: | |||

Grade | Sulphur | Phosphorous | Carbon Equivalent (CE)1 |

Max | Max | Max | |

A | 0.05 | 0.05 | 0.42 |

B | 0.045 | 0.045 | 0.41 |

C | 0.04 | 0.04 | 0.39 |

The Detail of steel billet

Name: | steel billets |

LENGTH: | 6 meter to 12 meter (+ 50mm) |

Size: | 100*100, 120*120, 150*150, 200*200 |

Grade: | 3SP,5SP,Q235,20MnSi. |

Shape: | Square, Round |

Technique: | Hot-Rolled |

Standard: | ASTM/GB |

BENDING | No more than 5mm in 1 meter |

ANGULAR TWIST | No more than 1 degree per meter and not more than 6 degree over 12 meter length. |

Chemical composition | C, Si, Mn, P, S, N, Cr |

Chemical Properties steel billet

Size | 60*60/90*90/100*100/120*120/150*150 |

Length | 6000mm-12000mm |

Standard | GB |

Applicaton | To produce bars or other applications |

Grade | Q195/Q235/Q275/3SP/5SP/20MnSi |

Packing terms | TT/LC |

Package | Mill's standard packing or as client's requirment |

Delivery time | Within 10-30 days after receiving the deposit or LC |

Chemical Composition steel billet

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

- Q: How are steel billets used in the manufacturing of packaging materials?

- Steel billets are used in the manufacturing of packaging materials by being rolled into thin sheets to create metal containers or cans. These billets are first heated and then passed through a series of rolling machines to achieve the desired thickness. These sheets are further processed and shaped to form different types of packaging materials such as cans, boxes, or containers, which provide durability and strength to protect and preserve various products during transportation and storage.

- Q: How are steel billets used in the manufacturing of packaging equipment?

- Steel billets are used in the manufacturing of packaging equipment as they serve as the raw material for various components and parts. These billets are melted down and shaped into the desired form, such as plates, bars, or tubes, which are then further processed to create the structural framework, frames, or supports required for packaging machinery. The strength, durability, and malleability of steel make it an ideal choice for constructing robust and reliable packaging equipment, ensuring efficient and safe packaging operations.

- Q: What is the role of steel billets in the manufacturing of cutting tools?

- Steel billets play a crucial role in the manufacturing of cutting tools as they are the starting material for producing high-quality tool steels. These billets are heated, forged, and machined to form the desired shape and size of cutting tools such as drills, saw blades, and milling cutters. The strength and durability of the cutting tools largely depend on the quality and composition of the steel billets used.

- Q: What are the different surface treatments for improved dimensional accuracy in steel billets?

- There are several surface treatments that can be employed to enhance dimensional accuracy in steel billets. These treatments aim to reduce surface imperfections, improve surface finish, and minimize dimensional variations. Some common surface treatments for improved dimensional accuracy in steel billets include: 1. Shot blasting: This process involves propelling abrasive particles at high velocity onto the surface of the billet. Shot blasting removes any dirt, scale, or surface contaminants, resulting in a smoother and cleaner surface. This treatment helps to eliminate any potential dimensional variations caused by surface irregularities. 2. Peeling: Peeling is a machining process in which a thin layer of material is removed from the surface of the billet using a cutting tool. This treatment helps to eliminate surface defects and imperfections, resulting in improved dimensional accuracy. Peeling can also enhance the surface finish of the billet. 3. Grinding: Grinding is a process in which an abrasive wheel or belt is used to remove material from the surface of the billet. This treatment helps to remove any surface irregularities, such as high spots or scratches, resulting in improved dimensional accuracy. Grinding can also provide a smoother and more uniform surface finish. 4. Turning: Turning is a machining process in which a cutting tool is used to remove material from the surface of the billet. This treatment helps to achieve precise dimensions and surface finish. Turning can also be used to improve concentricity and straightness of the billet. 5. Polishing: Polishing involves using abrasive materials or compounds to create a smooth and reflective surface on the billet. This treatment helps to remove any surface imperfections, such as scratches or blemishes, resulting in improved dimensional accuracy and surface finish. It is important to note that the choice of surface treatment may vary depending on the specific requirements and desired outcomes. Manufacturers often employ a combination of these treatments to achieve optimal dimensional accuracy in steel billets.

- Q: What are the main factors affecting the dimensional tolerances of steel billets?

- Various factors can influence the dimensional tolerances of steel billets. The manufacturing process itself is one of the main factors. The method employed to produce the billets, whether it be casting or hot rolling, can impact the final dimensions. Casting processes, for instance, can introduce variations in the cooling rate, thereby affecting the overall shape and size of the billets. Another crucial factor is the initial quality of the raw material. The composition and homogeneity of the steel utilized in billet production can contribute to dimensional variations. Impurities or uneven distribution of alloying elements can result in inconsistencies in the size and shape of the billets. The temperature maintained during the manufacturing process is also significant. High temperatures have the potential to cause thermal expansion, leading to dimensional changes in the billets. Proper control of cooling rates and the cooling process is vital to maintaining the desired tolerances. The design and condition of the manufacturing equipment can also impact dimensional tolerances. Adequate maintenance and calibration of machinery are essential to ensure consistent and accurate production. Lastly, external factors like handling and transportation can affect the dimensional tolerances of steel billets. Improper handling or rough transportation conditions can result in physical deformations or damage to the billets, leading to variations in their dimensions. In summary, achieving the desired dimensional accuracy in steel billets necessitates attention to factors such as the manufacturing process, raw material quality, temperature control, equipment condition, and handling and transportation practices.

- Q: What is the global production and consumption of steel billets?

- The global production and consumption of steel billets vary each year based on market demand and economic factors. However, steel billets are a crucial raw material in the steel industry, used for further processing into various steel products. The production and consumption of steel billets are significant in countries with a robust steel industry, such as China, India, the United States, and Russia. Accurate figures for global production and consumption can be obtained from industry reports and statistical data provided by organizations like the World Steel Association.

- Q: How do steel billets contribute to energy efficiency?

- Steel billets contribute to energy efficiency in several ways: 1. Production efficiency: Steel billets are the initial form of steel that is used in various manufacturing processes. By using steel billets as a starting material, manufacturers can achieve greater production efficiency. The uniform size and shape of billets allow for easier handling, cutting, and shaping, reducing energy consumption during the manufacturing process. 2. Resource optimization: Steel billets are typically made from recycled steel scrap. By using recycled steel as the raw material, manufacturers reduce the need for extracting and processing virgin iron ore, which is an energy-intensive process. This helps in conserving natural resources and reducing the overall energy consumption associated with steel production. 3. Heat recovery: During the manufacturing of steel billets, high temperatures are required to melt and shape the steel. However, modern steel plants are equipped with advanced technologies that allow for efficient heat recovery. The excess heat generated during the process can be captured and utilized for various purposes, such as generating steam or heating other areas of the plant. This heat recovery system helps to reduce energy wastage and increase overall energy efficiency. 4. Energy-efficient equipment: Steel billet production often involves the use of heavy machinery and equipment. Manufacturers are increasingly investing in energy-efficient technologies and equipment to reduce energy consumption. For example, using more efficient electric arc furnaces or induction heating systems can significantly reduce energy requirements compared to traditional methods. These advancements in technology contribute to the overall energy efficiency of steel billet production. Overall, steel billets play a crucial role in energy efficiency within the steel industry. From production efficiency to resource optimization and heat recovery, the use of steel billets helps in minimizing energy consumption and promoting a more sustainable steel manufacturing process.

- Q: How do steel billets contribute to the overall seismic resistance of a structure?

- The overall seismic resistance of a structure is greatly improved by the presence of steel billets. When incorporated into concrete structures, steel billets act as reinforcement, boosting the structure's strength and longevity. This reinforcement enables the structure to better endure the forces and vibrations unleashed by earthquakes. The impressive tensile strength of steel billets enables them to efficiently absorb and distribute seismic energy, significantly decreasing the likelihood of structural failure during an earthquake. Moreover, steel billets have the capacity to be transformed into specialized structural elements, such as braces or shear walls, which are strategically positioned within the structure to counteract the lateral forces resulting from earthquakes. By utilizing steel billets, these structural elements are able to effectively absorb and disperse the seismic energy, successfully safeguarding the overall structure from substantial harm. Furthermore, steel billets are instrumental in the construction of seismic dampers, which are devices created to soak up and dissipate the energy generated by seismic events. When steel billet-based dampers are installed, the structure is able to significantly diminish the transfer of seismic energy to the building, thereby minimizing the potential for damage. Additionally, steel billets possess outstanding ductility, which is the capacity to deform without breaking. During an earthquake, structures experience considerable movement and vibrations. The ductile nature of steel allows it to flex and bend under these forces, proficiently absorbing seismic energy and preventing sudden, catastrophic failure of the structure. In conclusion, steel billets enhance the overall seismic resistance of a structure by providing additional strength and durability, facilitating the creation of specialized structural elements, enabling the construction of seismic dampers, and offering exceptional ductility. Their application elevates the structure's ability to withstand seismic forces, reducing the risk of damage and ensuring the safety of its occupants.

- Q: How are steel billets used in the manufacturing of wire products?

- Steel billets are used in the manufacturing of wire products by being hot rolled into thin rods or wires, which are then further processed to achieve the desired shape and dimensions. These billets serve as the raw material for wire drawing, where they are pulled through a series of dies to reduce their size and increase their length. This process helps to improve the strength, ductility, and surface finish of the wire, making it suitable for various applications such as construction, automotive, and electrical industries.

- Q: How do steel billets contribute to the automotive industry?

- The automotive industry heavily relies on steel billets as the primary raw material for manufacturing different automotive components. These components, including engine parts, transmission systems, chassis, suspension systems, and other critical parts, are crucial for ensuring the safety, performance, and durability of vehicles. A significant contribution of steel billets to the automotive industry lies in their exceptional strength and durability. Steel is widely known for its high tensile strength, which enables it to withstand extreme forces and provide structural integrity to automotive components. This strength is particularly crucial in areas such as the frame, where it ensures passenger safety in the event of a collision. Moreover, steel billets offer excellent formability and versatility, allowing manufacturers to create intricate and complex automotive parts with precision. This enables the production of components that meet the specific design requirements of different vehicle models, ensuring optimal performance and functionality. Another advantage of steel billets is their cost-effectiveness. Compared to alternatives like aluminum or carbon fiber, steel is a relatively affordable material. Its widespread availability and production efficiency make it an economical choice for mass production, helping to keep vehicle prices reasonable for consumers. Furthermore, steel billets possess excellent heat resistance and thermal conductivity properties, making them ideal for use in engine components, such as pistons and cylinder heads. They can withstand high temperatures and efficiently transfer heat. Additionally, steel billets contribute to the sustainability of the automotive industry. Steel is highly recyclable, with a recycling rate of around 90%. This allows for the eco-friendly disposal and reuse of steel components, reducing the environmental impact of the automotive manufacturing process. In conclusion, steel billets play a crucial role in the automotive industry by providing the necessary strength, durability, formability, and cost-effectiveness for manufacturing various automotive components. Their versatility and recyclability further contribute to the sustainability of the industry. Without steel billets, the automotive industry would face challenges in producing safe, reliable, and affordable vehicles.

Send your message to us

chrome alloy square mild steel billets prime billet steel for building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords