PVC roofing and waterproofing membrane manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC roofing and waterproofing membrane

1. Introduction

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is

made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet

absorber and other auxiliaries.

2. Specification

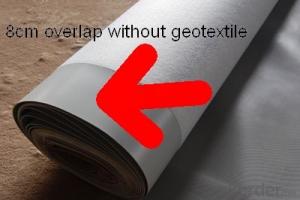

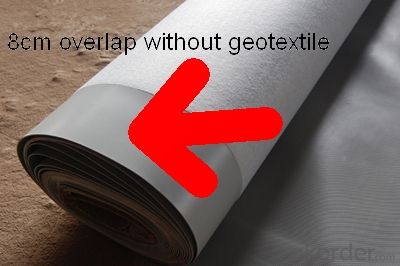

1) Size: 2.05(width)*20m (length)

2) Thickness: 1.2mm; 1.5mm; 2.0mm

3) Type: Homogeneous, Reinforced, With fabric back

4) Exposed and Non-exposed

5) Color: white, Grey or customized

6) Certificate: ISO9001/14001

3. Applications

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

4. Features

1) Excellent aging resistance.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

- Q: Can a waterproofing membrane be used in residential buildings?

- Yes, a waterproofing membrane can be used in residential buildings. It is commonly used in basements, bathrooms, and other areas prone to moisture to prevent water damage and leakage.

- Q: Can waterproofing membranes be used on foundation walls?

- Yes, waterproofing membranes can be used on foundation walls. These membranes are designed to prevent water penetration and protect the foundation from moisture damage.

- Q: Can a waterproofing membrane be used on EPDM roofs?

- Yes, a waterproofing membrane can be used on EPDM roofs. EPDM roofs are typically made from a rubber material, and a waterproofing membrane can provide an additional layer of protection against water infiltration, extending the lifespan of the roof.

- Q: Can a waterproofing membrane be used in coastal areas?

- Indeed, the utilization of a waterproofing membrane is viable in coastal regions. Given their susceptibility to copious amounts of moisture and water exposure, it becomes imperative to implement efficient waterproofing measures. By appropriately installing and upkeeping a waterproofing membrane, one can establish a protective barrier, effectively thwarting water infiltration and averting structural damage while ensuring their longevity. Nevertheless, it is crucial to opt for a membrane specifically tailored for coastal environments as they exhibit heightened resistance to saltwater and possess superior durability to withstand the harsh coastal conditions. Moreover, routine inspection and maintenance are imperative to guarantee the continued efficacy of the waterproofing membrane in coastal areas.

- Q: Can a waterproofing membrane be used for above-grade applications?

- Indeed, above-grade applications can benefit from the use of a waterproofing membrane. In construction, waterproofing membranes are widely employed to safeguard structures against water infiltration and subsequent harm. While they are commonly utilized for below-grade purposes like basements and foundations, waterproofing membranes can also be applied above-grade on surfaces such as roofs, decks, and exterior walls. When utilized above-grade, waterproofing membranes serve as an effective moisture barrier, preventing water from permeating the structure. These membranes are specifically designed to endure prolonged exposure to various elements, including rain, snow, and UV rays. By effectively sealing the surface, a waterproofing membrane aids in shielding the structure from water damage, mold growth, and deterioration. Several types of waterproofing membranes are available for above-grade applications, including liquid-applied membranes, sheet membranes, and self-adhering membranes. These membranes are typically constructed from materials such as modified bitumen, polyurethane, or rubberized asphalt, which possess exceptional waterproofing properties. Proper surface preparation is crucial when installing a waterproofing membrane above-grade. The surface must be thoroughly cleansed, completely dry, and devoid of any substances that might undermine the membrane's adhesion. Additionally, it is vital to adhere to the manufacturer's instructions and guidelines regarding application techniques and recommended thickness. In conclusion, a waterproofing membrane can effectively shield structures from water infiltration and damage when used in above-grade applications. By selecting the appropriate membrane type and adhering to proper installation procedures, a durable and dependable waterproofing system can be established for above-grade surfaces.

- Q: How does a waterproofing membrane handle freeze-thaw cycles?

- A waterproofing membrane is designed to withstand freeze-thaw cycles by having specific properties that enable it to expand and contract without compromising its integrity. Freeze-thaw cycles occur when water penetrates the membrane and freezes during colder temperatures, causing it to expand. As the ice melts during warmer temperatures, the membrane should have the ability to contract back to its original state. To handle freeze-thaw cycles, a waterproofing membrane typically possesses elasticity and flexibility, allowing it to accommodate the expansion and contraction without cracking or breaking. It may also have a low water absorption rate to prevent water from seeping into the membrane. Additionally, the membrane should have excellent adhesion to the substrate to ensure it remains in place during temperature fluctuations. Some waterproofing membranes incorporate special additives or technology to enhance their freeze-thaw resistance. These additives may include polymers or elastomers that improve the membrane's ability to withstand extreme temperature changes. Moreover, some membranes have reinforced layers or fabric inserts that provide additional strength and durability, helping them better handle freeze-thaw cycles. Overall, a well-designed waterproofing membrane should be able to handle freeze-thaw cycles effectively by being elastic, flexible, resistant to water absorption, and strongly adhered to the substrate. This ensures the membrane's longevity and prevents water infiltration, protecting structures from potential damage caused by freeze-thaw cycles.

- Q: Can a waterproofing membrane be used in swimming pools or water features?

- Yes, a waterproofing membrane can be used in swimming pools or water features. Waterproofing membranes are often used in these applications to create a barrier between the water and the surrounding structure. This helps prevent water leakage and damage to the structure, ensuring the longevity and durability of the swimming pool or water feature. The membrane is typically applied to the surface of the structure and can be made of various materials such as rubber, PVC, or bitumen. It is important to choose a membrane that is specifically designed for underwater applications to ensure its effectiveness in providing a watertight seal. Additionally, proper installation and regular maintenance of the waterproofing membrane are crucial to ensure its long-term performance.

- Q: Are there any specific installation techniques for corners and edges when using a waterproofing membrane?

- Yes, when installing a waterproofing membrane on corners and edges, it is important to follow specific techniques. First, ensure that the membrane extends beyond the corner or edge by at least 6 inches to provide adequate coverage. Next, carefully fold and crease the membrane to create a tight seal around the corner or edge. Use a heat gun or adhesive to secure the folded membrane in place. Additionally, apply a layer of sealant or waterproofing tape over the folded membrane to further reinforce the corner or edge. These techniques help prevent water penetration and ensure effective waterproofing in these vulnerable areas.

- Q: Can waterproofing membranes be used on buried pipelines?

- Buried pipelines can benefit from the use of waterproofing membranes. These membranes are specifically designed to shield against water and moisture, and can be applied to a variety of surfaces, including buried pipelines. Typically, these membranes are constructed from materials like bitumen or synthetic polymers, which possess resistance to water penetration. When employed on buried pipelines, waterproofing membranes serve to prevent water infiltration, a process that can lead to corrosion and material deterioration. Acting as a barrier, they effectively halt water from reaching the surface of the pipeline, safeguarding it from potential moisture-induced harm. Furthermore, waterproofing membranes also offer protection against external elements like soil chemicals or gases, which may pose threats to the pipeline. By establishing a waterproof barrier, these membranes effectively extend the lifespan of buried pipelines, diminish maintenance expenses, and enhance overall performance. It is important to emphasize that the selection and application of waterproofing membranes should be entrusted to professionals who possess extensive knowledge in pipeline construction and waterproofing systems. Ensuring the effectiveness of these membranes requires proper installation techniques and compatibility with the pipeline material.

- Q: Can a waterproofing membrane be used for elevator pits or sump pits?

- Yes, a waterproofing membrane can be used for elevator pits or sump pits. Elevator pits and sump pits are areas that are prone to water intrusion, so it is important to protect them from water damage. A waterproofing membrane is designed to create a barrier against water, preventing it from seeping into the pits and causing damage to the structure or equipment. By applying a waterproofing membrane to the walls and floors of elevator pits or sump pits, it helps to keep the area dry and free from water infiltration. This can help extend the lifespan of the elevator or sump pump system and prevent costly repairs in the future. It is important to properly install and maintain the waterproofing membrane to ensure its effectiveness and longevity.

Send your message to us

PVC roofing and waterproofing membrane manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords