China Manufacturer Top Quality PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

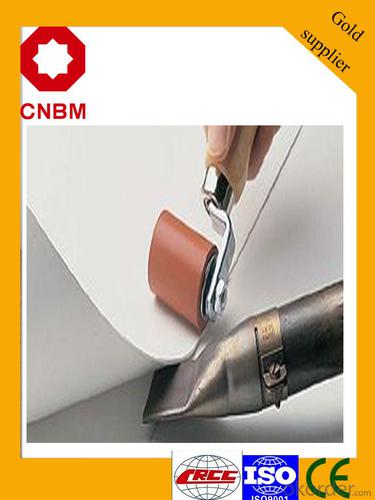

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Are waterproofing membranes resistant to extreme weather conditions?

- Yes, waterproofing membranes are designed to be highly resistant to extreme weather conditions. They are engineered to withstand heavy rain, snow, high winds, and temperature fluctuations without compromising their effectiveness. They provide a durable barrier against moisture, protecting structures from water damage, leaks, and potential structural issues caused by extreme weather.

- Q: Is a waterproofing membrane resistant to rodent or insect infestation?

- Yes, a waterproofing membrane can be resistant to rodent or insect infestation. Most waterproofing membranes are made of materials that are not attractive to rodents or insects, such as bitumen or synthetic polymers. Additionally, these membranes are typically installed in a way that leaves no gaps or openings for pests to enter. However, it is important to note that no waterproofing system is completely immune to infestation. If there are pre-existing entry points or if the membrane is damaged or improperly installed, rodents or insects may still be able to penetrate the waterproofing system. Regular inspection and maintenance are crucial to ensure the integrity of the waterproofing membrane and prevent any infestation from occurring.

- Q: Can a waterproofing membrane be used in areas with extreme weather conditions, such as hurricanes or snowstorms?

- Yes, a waterproofing membrane can be used in areas with extreme weather conditions, such as hurricanes or snowstorms. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can effectively withstand various weather conditions. They are made from materials that are resistant to moisture and can be installed in different areas like roofs, basements, or foundations. In regions prone to hurricanes, waterproofing membranes can help prevent water damage by creating a barrier that keeps water out even during heavy rainfall or storm surges. These membranes are often reinforced and have high tensile strength to withstand the strong winds and pressure associated with hurricanes. Similarly, in areas with heavy snowstorms, waterproofing membranes can help prevent water intrusion caused by melting snow or ice dams. They are designed to be flexible and resistant to extreme temperatures, ensuring that they maintain their integrity and prevent leaks even in freezing conditions. However, it is important to choose the right type of waterproofing membrane suitable for the specific weather conditions in the area. Different membranes have varying levels of resistance to extreme weather, so it is advisable to consult with a professional to determine the most appropriate membrane for the specific climate and weather patterns. Additionally, proper installation and regular maintenance are crucial to ensure the longevity and effectiveness of the waterproofing system in extreme weather conditions.

- Q: Can a waterproofing membrane be used on concrete?

- Yes, a waterproofing membrane can be used on concrete. In fact, it is a commonly used method to prevent water penetration and protect concrete structures from moisture damage. A waterproofing membrane is a thin layer of material that is applied on the surface of the concrete to create a barrier against water and moisture. It can be made from various materials such as bitumen, rubberized asphalt, polyurethane, or acrylic. The membrane is typically applied in liquid or sheet form and adheres to the concrete surface to form a continuous and impermeable coating. This coating prevents water from seeping into the concrete, which can cause degradation, cracks, and other forms of damage. Waterproofing membranes are widely used in various concrete applications, including basements, foundations, roofs, and other structures that are exposed to moisture or water.

- Q: How does a waterproofing membrane handle construction vibrations?

- To withstand construction vibrations, a waterproofing membrane is created as a durable and flexible barrier. This membrane, typically composed of materials like rubberized asphalt or synthetic polymers, possesses remarkable elasticity and tensile strength. When construction vibrations occur, the waterproofing membrane absorbs and disperses them, safeguarding the building's structural integrity and the waterproofing system. The membrane's flexibility enables it to stretch and contract, accommodating the vibrations without experiencing cracks or tears. Moreover, certain waterproofing membranes include features like reinforced layers or fabric reinforcement, which augment their ability to endure construction vibrations. These reinforcements provide extra strength and stability, rendering the membrane more resistant to damage from vibrations. It is crucial to recognize that the effectiveness of a waterproofing membrane in handling construction vibrations is influenced by the quality of installation. Proper installation methods, encompassing adequate surface preparation and appropriate adhesion techniques, ensure that the membrane is securely affixed to the substrate, thereby minimizing the risk of displacement or damage during construction activities. In conclusion, a waterproofing membrane is specially designed to handle construction vibrations by absorbing and dispersing their impact, while maintaining its integrity and waterproofing capabilities. The membrane's flexibility and strength, combined with proper installation techniques, guarantee its ability to withstand the challenges posed by construction vibrations and provide enduring protection against water intrusion.

- Q: Is a waterproofing membrane resistant to solvents or chemical spills?

- Generally, waterproofing membranes tend to resist solvents and chemical spills. They are engineered to shield against water and other liquids, including solvents and chemicals. These membranes often consist of materials like PVC, TPO, or EPDM, which exhibit impressive resistance to different solvents and chemicals. Nevertheless, the degree of resistance can differ based on the membrane's type and composition. It is advisable to review the manufacturer's specifications and seek guidance from experts to confirm the membrane's compatibility with particular solvents or chemicals prior to installation.

- Q: What is the recommended temperature range for applying a waterproofing membrane?

- The recommended temperature range for applying a waterproofing membrane typically varies depending on the specific product being used. However, in general, it is advisable to apply the membrane within a temperature range of 50°F to 90°F (10°C to 32°C). This temperature range ensures optimal bonding and curing of the membrane, allowing for effective waterproofing. It is important to follow the manufacturer's instructions and guidelines for the specific product being used, as they may provide more specific temperature recommendations based on their formulation and application process. Additionally, it is crucial to consider the ambient temperature and conditions during application, as extreme temperatures or weather conditions can affect the performance and effectiveness of the waterproofing membrane.

- Q: Can waterproofing membranes be used on plant rooms?

- Yes, waterproofing membranes can be used on plant rooms. Plant rooms often contain equipment and machinery that require protection from water damage. Waterproofing membranes provide a barrier against water infiltration, preventing leaks and potential damage to the plant room and its contents. These membranes are typically applied to the walls, floors, and roofs of the plant room to ensure complete waterproofing. Additionally, waterproofing membranes can also offer protection against other elements such as chemicals and temperature fluctuations, making them an ideal solution for plant rooms.

- Q: What is the use of waterproof membrane?

- It is the first barrier between the foundation of the project and the building, which is the first barrier to the entire project. It plays a vital role in the whole project.

- Q: Does a waterproofing membrane require any specific primers or bonding agents for installation?

- Yes, a waterproofing membrane often requires specific primers or bonding agents for proper installation. These primers or bonding agents are designed to ensure proper adhesion between the membrane and the substrate, enhancing the overall effectiveness and longevity of the waterproofing system. The type of primer or bonding agent required may vary depending on the specific membrane and substrate materials being used. It is important to consult the manufacturer's guidelines or seek advice from a waterproofing professional to determine the appropriate primer or bonding agent for your specific project to ensure a successful installation.

Send your message to us

China Manufacturer Top Quality PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords