PVC Roofing Membrane PE membrane SBS waterproof Membrane In Chinese Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

Self-adhesive polymer modified bitumen membrane systems is based on synthetic rubber and resin modified asphalt by adding activity agent, polyester felt or fiberglass felt, polyethylene as the child-based, polyethylene film as surface materials, or without membrane (double-sided self-adhesive), using silicone oil separated anti-adhesive membrane.

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Characteristic

1.high adhesive.

2.anti distortion.

3.Non toxic,tasteless,environmentally friendly.

4.Not strict requirement for the substrate, save time

Applicable scope:

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application method:

1.Make sure the roof deck smooth ,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2.There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3.After application ,a full serious inspection is required to make sure no air bubble ,no fold,no falling away etc to guarantee the waterproof life.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Product usage of pe compound waterproof membrane

The products are widely used in projects of compound geomembrane impervious

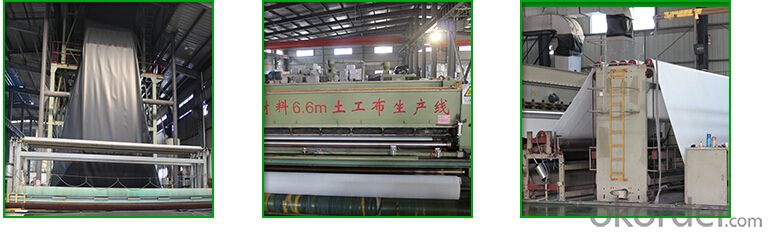

Product line&test

♦Product line

From raw materials to finished products, every process is tested and controlled professionally and seriously by our professional machines and person.

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Why choose us ?

We have 20 years manufacturer experience

10000-30000 square meter factory size,more than 10 production lines

We will be your best partner,provide high quality products with CE,ISO,SGS

approved in competitive prive,sincerely hope to make a win-win cooperation with you.

FAQ

- Q: Can a waterproofing membrane be used on parking garages?

- Indeed, utilizing a waterproofing membrane is highly recommended for parking garages to safeguard the structure against water damage. Parking garages are exposed to varying weather conditions, including rain, snow, and ice, which can lead to water infiltration through cracks, joints, or porous concrete. This infiltration can result in corrosion of reinforcing steel, degradation of concrete, and compromise the overall integrity of the structure. A waterproofing membrane serves as a specialized barrier system designed explicitly to impede water penetration and shield the underlying structure. Typically composed of materials like modified bitumen, PVC, or liquid applied coatings, the flexible membrane is applied to the surface of the parking garage, delivering a seamless and resilient waterproof barrier. Using a waterproofing membrane for parking garages offers numerous advantages. Firstly, it significantly prolongs the lifespan of the structure by shielding it from water-induced deterioration. Secondly, it upholds the structural integrity of the garage by preventing reinforcing steel corrosion, which can gradually weaken the structure. Furthermore, a waterproofing membrane maintains a dry and secure environment within the parking garage, thereby reducing the risk of slip and fall accidents. It is crucial to consider the specific requirements and conditions of the parking garage when selecting the appropriate waterproofing membrane. Factors such as the type of parking garage (underground, above ground, or rooftop), traffic volume, presence of vehicular fluids, and climate should all be taken into account when choosing the suitable waterproofing membrane system. In conclusion, to safeguard parking garages from water damage, extend their lifespan, and ensure a safe environment for users, the use of a waterproofing membrane is both viable and essential.

- Q: Are there any specific requirements for installing a waterproofing membrane?

- Yes, there are specific requirements for installing a waterproofing membrane. Some key requirements include ensuring a clean and dry surface, proper preparation of the substrate, correct application of the membrane according to manufacturer's instructions, and adequate curing time. Additionally, ensuring proper seam and joint treatments, as well as sufficient overlap and termination details, are essential for an effective waterproofing installation. It is crucial to follow the specific guidelines and recommendations provided by the manufacturer to ensure a successful and long-lasting waterproofing system.

- Q: Can a waterproofing membrane be used for a residential building?

- A residential building can utilize a waterproofing membrane for its protection. This membrane is a thin material layer applied to the building's exterior walls, foundation, or roof to prevent water from entering the structure. It acts as a barrier against moisture, preventing water damage, mold growth, and enhancing energy efficiency by reducing heat loss. The implementation of a waterproofing membrane in a residential building can be done in multiple areas like basements, bathrooms, balconies, roofs, and exterior walls. It is particularly beneficial in areas prone to water infiltration, such as basements where groundwater seepage may occur or bathrooms where moisture problems can arise from water splashes and steam. Various types of waterproofing membranes are available, including liquid-applied membranes, sheet membranes, and self-adhering membranes. These membranes are designed to be long-lasting, flexible, and resistant to water, ensuring durability and effectiveness in protecting the residential building. By utilizing a waterproofing membrane, homeowners can safeguard their property from water damage, structural issues, and health risks associated with moisture intrusion. It is crucial to seek professional advice to determine the most suitable type of waterproofing membrane for the residential building based on factors like location, climate, and potential sources of water infiltration.

- Q: Does a waterproofing membrane provide any UV resistance?

- Indeed, a certain level of UV resistance can be achieved with the use of a waterproofing membrane. Numerous waterproofing membranes are specifically crafted for outdoor usage, where they will inevitably come into contact with sunlight. These membranes frequently contain UV stabilizers or additives to shield against the harmful impact of UV rays. Nevertheless, it is crucial to acknowledge that the degree of UV resistance offered by a waterproofing membrane may differ depending on the product and manufacturer. It is highly advisable to consult the manufacturer's specifications and guidelines for precise information on the UV resistance capabilities of a specific waterproofing membrane.

- Q: Can a waterproofing membrane prevent mold and mildew growth?

- A waterproofing membrane has the ability to prevent the growth of mold and mildew. Mold and mildew thrive in areas that are damp and moist, but waterproofing membranes act as a barrier that stops water from seeping into the surfaces below. By ensuring that the area remains dry, the membrane reduces the conditions needed for mold and mildew to grow. Furthermore, certain waterproofing membranes are specifically designed to have antimicrobial properties, which further hinder the growth of mold and mildew. However, it is important to remember that while a waterproofing membrane can help prevent mold and mildew growth, it is not a guaranteed solution. Proper ventilation and maintenance are also essential in preventing these problems.

- Q: Can a waterproofing membrane be applied to tiled surfaces?

- Yes, a waterproofing membrane can be applied to tiled surfaces. In fact, it is common practice to use a waterproofing membrane underneath tiled surfaces, especially in areas prone to moisture such as bathrooms, showers, and kitchen backsplashes. The waterproofing membrane acts as a barrier to prevent water penetration into the substrate, protecting the tiles and the underlying structure from water damage. It is important to ensure that the tiled surface is properly prepared and free from any cracks or damage before applying the waterproofing membrane to achieve optimal results.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Indeed, adobe block surfaces can be treated with a waterproofing membrane. These blocks, composed of a blend of clay, sand, and straw, are prone to water damage. By applying a waterproofing membrane, the infiltration of water can be prevented, thus safeguarding the adobe blocks against various moisture-related problems like cracking, erosion, or mold formation. It is essential to verify that the waterproofing membrane is suitable for adobe surfaces and adhere to the manufacturer's instructions for application. Furthermore, prior to applying the membrane, it is vital to adequately prepare the surface and address any preexisting damages to ensure optimal performance.

- Q: Can a waterproofing membrane be used for bridges or parking decks?

- Yes, a waterproofing membrane can be used for bridges or parking decks. Waterproofing membranes are commonly used in these structures to protect them from water damage and extend their lifespan by preventing water infiltration and corrosion. The membrane acts as a barrier, preventing water from seeping into the structure and causing structural deterioration or compromising the integrity of the bridge or parking deck.

- Q: Is a waterproofing membrane suitable for both residential and commercial applications?

- Yes, a waterproofing membrane is suitable for both residential and commercial applications. It provides a protective barrier against moisture and can be used in various areas such as basements, roofs, and bathrooms, making it ideal for both residential and commercial buildings.

- Q: Can a waterproofing membrane be used on precast concrete block surfaces?

- Yes, a waterproofing membrane can be used on precast concrete block surfaces. It helps to prevent water penetration and protects the structure from potential damage caused by moisture.

Send your message to us

PVC Roofing Membrane PE membrane SBS waterproof Membrane In Chinese Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords