Polyvinyl Chloride (PVC) Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

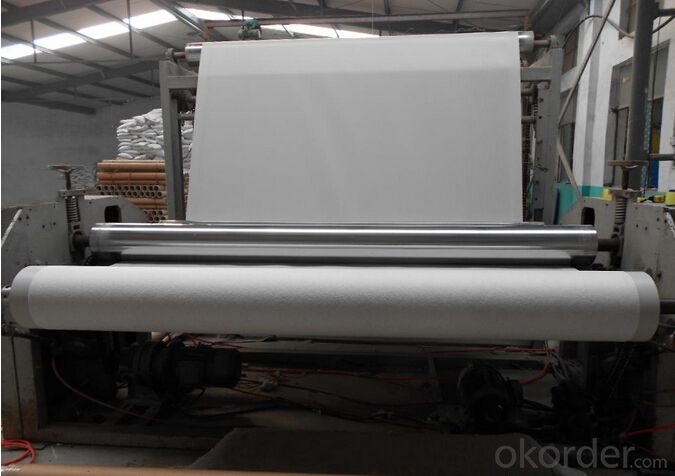

1. Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

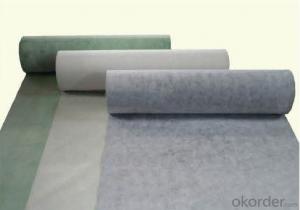

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

2. Introduction of PVC Waterproofing Membrane

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

3. Features of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

4. Types of PVC Waterproofing Membrane

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric.

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

5. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are waterproofing membranes suitable for residential basements?

- Yes, waterproofing membranes are suitable for residential basements. Waterproofing membranes are designed to prevent water infiltration and protect the basement from moisture damage. They can be applied to the exterior or interior of the basement walls to create a barrier against water and dampness. This helps to prevent issues such as mold growth, water damage, and structural deterioration. Waterproofing membranes are an effective solution for residential basements as they provide long-lasting protection and can help to create a dry and healthy living environment.

- Q: Does a waterproofing membrane prevent water damage to building materials?

- Yes, a waterproofing membrane is designed to create a barrier that prevents water from seeping into building materials, thus effectively preventing water damage.

- Q: Can a waterproofing membrane be used for temporary structures or tents?

- Indeed, temporary structures or tents can benefit from the utilization of a waterproofing membrane. These membranes are specifically crafted to create a safeguarding shield against water, thwarting any potential harm caused by water infiltration. Consequently, they prove to be an excellent selection for temporary structures or tents, ensuring that the interior remains dry in inclement weather or damp environments. Furthermore, the lightweight and pliable nature of waterproofing membranes simplifies their installation and removal, which is particularly advantageous for temporary structures or tents that necessitate relocation or disassembly.

- Q: Can a waterproofing membrane be used for vehicular traffic areas?

- Yes, a waterproofing membrane can be used for vehicular traffic areas. Waterproofing membranes are designed to protect surfaces from water damage by creating a barrier that prevents water from seeping through. In vehicular traffic areas, such as parking decks or driveways, it is important to protect the underlying structure from water infiltration, which can cause corrosion, deterioration, and expensive repairs. By using a waterproofing membrane specifically designed for vehicular traffic, the surface can be adequately protected from water damage, as well as other potential contaminants like oil and chemicals. These membranes are typically more durable and able to withstand the weight and impact of vehicles, ensuring long-lasting protection. Additionally, some waterproofing membranes offer slip-resistant properties, making them suitable for use in areas where vehicles may need traction. However, it is crucial to consult with a professional to determine the appropriate waterproofing membrane and installation method for specific vehicular traffic areas based on factors such as traffic volume, load capacity, and climate conditions.

- Q: Can a waterproofing membrane be used in interior or exterior applications?

- Yes, a waterproofing membrane can be used in both interior and exterior applications. It is commonly used in basements, bathrooms, and other areas prone to moisture and water infiltration. Additionally, it can also be applied to exterior surfaces such as foundations, roofs, and balconies to prevent water damage and maintain the integrity of the structure.

- Q: Can a waterproofing membrane be used on nickel surfaces?

- Yes, a waterproofing membrane can be used on nickel surfaces. The membrane will provide a protective barrier against moisture and prevent water penetration into the nickel surface.

- Q: Can a waterproofing membrane be used in crawlspaces or basements?

- Using a waterproofing membrane in crawlspaces or basements is highly recommended. These areas are prone to water seepage and high humidity levels, which can cause mold growth, structural issues, and damage to stored items. By effectively sealing the foundation walls and floor, a waterproofing membrane acts as a barrier against water intrusion. It creates a watertight seal that keeps the space dry and protected. Furthermore, waterproofing membranes help control moisture levels by reducing condensation and humidity, creating a healthier and more comfortable environment. Overall, using a waterproofing membrane in crawlspaces or basements is crucial for ensuring the structure's longevity and integrity and protecting against potential water-related problems.

- Q: Are waterproofing membranes suitable for residential applications?

- Indeed, residential applications can benefit greatly from the use of waterproofing membranes. These membranes find widespread use in a variety of residential construction areas, including basements, foundations, roofs, bathrooms, and balconies. Their primary purpose is to safeguard the building structure by preventing water penetration and moisture damage. Waterproofing membranes function as a barrier that effectively blocks water from infiltrating the structure, thereby averting problems such as mold growth, rot, or structural deterioration. These membranes commonly consist of materials such as bitumen, PVC, EPDM, or polyurethane, which possess exceptional water-repelling properties. During the construction or renovation process of residential buildings, waterproofing membranes are typically installed. They can be applied in the form of liquid coatings or sheets that are meticulously laid down and firmly affixed to the surface. These membranes create a seamless and long-lasting barrier that can withstand the test of time. Moreover, waterproofing membranes offer numerous advantages for residential applications. They help maintain a dry and comfortable living environment by preventing water leaks and dampness. As a result, they safeguard the integrity of the building materials, extend the lifespan of the structure, and minimize the likelihood of expensive repairs. Furthermore, these membranes contribute to enhanced energy efficiency by reducing heat loss or gain caused by moisture infiltration. By effectively blocking water, they assist in maintaining consistent temperatures inside the house, which leads to reduced energy consumption and lower utility bills. In conclusion, waterproofing membranes are an exceptional choice for residential applications. They provide dependable protection against water damage, enhance the longevity of the structure, and contribute to a healthier and more energy-efficient living environment.

- Q: Are waterproofing membranes resistant to hydrostatic pressure?

- Waterproofing membranes have been specifically developed to resist hydrostatic pressure, which is the pressure exerted by still water. When a building is exposed to ground water, such as in basements or foundations, hydrostatic pressure becomes a significant concern as it can lead to water seeping through walls and floors. To prevent water from penetrating the building structure, waterproofing membranes are engineered to withstand and resist the pressure exerted by water. These membranes are typically made from materials like bitumen, rubberized asphalt, or synthetic polymers, all of which possess excellent water resistance properties. Moreover, the purpose of waterproofing membranes is to create an uninterrupted barrier against water, effectively preventing any potential leaks or seepage. They are applied in multiple layers, ensuring a sturdy and long-lasting barrier that can withstand the high pressure of water. It is crucial to note that the effectiveness of the waterproofing membrane in resisting hydrostatic pressure may vary depending on its type and quality. Hence, it is essential to choose a high-quality membrane and ensure proper installation to maximize its ability to resist hydrostatic pressure.

- Q: Can a waterproofing membrane be installed on a roof?

- Yes, a waterproofing membrane can be installed on a roof. A waterproofing membrane is a type of material that is specifically designed to provide a protective layer on a surface, preventing water from seeping through. When installed on a roof, a waterproofing membrane acts as a barrier against moisture, preventing leaks and water damage to the underlying structure. It is commonly used in flat or low-sloped roofs, where water can accumulate and cause issues. The installation process typically involves cleaning and preparing the roof surface, applying the membrane in overlapping layers, and securing it with adhesives, fasteners, or heat welding. Additionally, a waterproofing membrane can also help in extending the lifespan of a roof by protecting it from UV rays, temperature fluctuations, and other environmental factors. Overall, installing a waterproofing membrane on a roof is an effective way to ensure its long-term durability and prevent water-related problems.

Send your message to us

Polyvinyl Chloride (PVC) Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords