Chinese Best Hot-dip Zinc Coating Steel Building Roof Walls JIS G3302

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

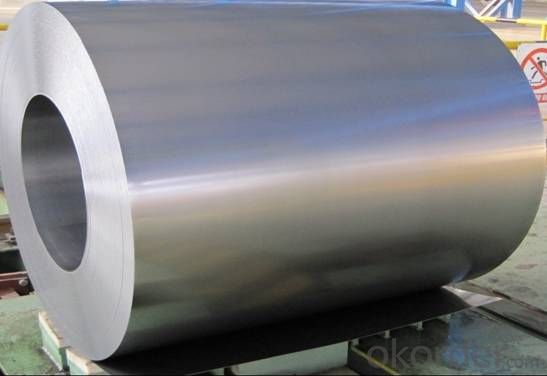

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

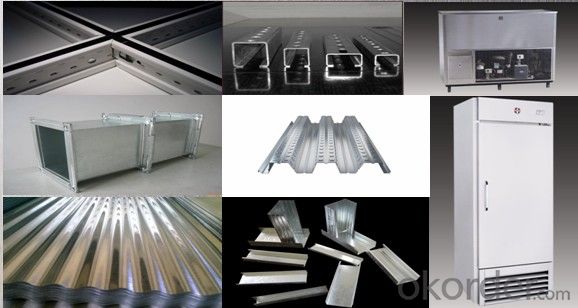

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

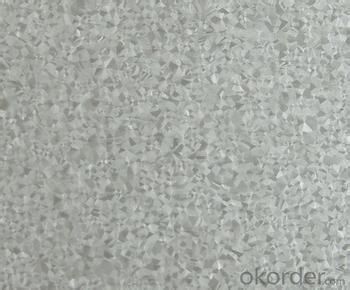

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What is the role of steel coils in the manufacturing of agricultural machinery?

- Steel coils are essential in the manufacturing of agricultural machinery as they are used to form various components such as frames, chassis, and structural supports. These coils provide the necessary strength, durability, and rigidity required to withstand the demanding conditions and heavy workload typically encountered in the agricultural sector.

- Q: What are the main factors that affect the price of steel coils?

- The main factors that affect the price of steel coils include the cost of raw materials, such as iron ore and scrap metal, as well as the demand and supply dynamics in the market. Other influential factors include energy costs, transportation expenses, production capacity, and geopolitical factors that can impact global trade. Additionally, fluctuations in currency exchange rates and government regulations on trade and tariffs can also influence the price of steel coils.

- Q: Is steel with a black coloring as strong as regular steel. if you are asking why i have two wordsBlack Katana.I know a katana is not made with normal steel, it is made of two types with varying grades of carbon to give it speacial properties, i just want to know if the black will make a difference.

- The term tensile potential refers back to the quantity of tensile (stretching) rigidity a textile can stand up to in the previous breaking or failing. the in simple terms suitable tensile potential of a textile is calculated by making use of dividing the element of the textile examined (the pass area) by making use of the strain located on the textile, regularly expressed in terms of pounds or much consistent with sq. inch of fabric. Tensile potential is an considerable degree of a textile's skill to accomplish in an utility, and the scale is extensively used whilst describing the residences of metals and alloys.

- Q: I am looking to weld some stainless steel using stainless electrodes. I was told that the arc welder needs to be able to run in DC in order to be able to weld stainless steel. Is this true? Or can you weld stainless steel with stainless electrodes with AC also?

- Arc or stick welding is not ideal for stainless steel. It is advisable to use MIG or TIG welding instead, with argon shield gas. I would only advise manual arc welding as a last resort, or for field repairs. Expect corrosion issues, and issues with excessive oxidation and porosity in your stainless welds. Manual arc welding is a dirty process and simply does not protect the weld puddle well enough from oxidation and carbon pickup, which are especially damaging in sensitive stainless alloys. As to whether to use AC or DC for stick welding, you should consult the instructions found on the box of electrodes. If polarity and current recommendations cannot be found, then you should contact the manufacturer and get it in writing. You should probably not make welding decisions based on advice from a sales representative. Firstly is is not documented. Secondly, sales representatives are not legally liable for damages caused by weld failures, YOU are.

- Q: How are steel coils used in the production of agricultural trailers?

- Steel coils are used in the production of agricultural trailers as they are formed into various structural components such as frames, chassis, and supports. These coils are cut, shaped, and welded to create a sturdy and durable trailer structure that can withstand heavy loads and rough terrains commonly encountered in agricultural operations.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts as they serve as the primary raw material. The coils are unwound and fed into a machine that cuts and shapes the steel into bolts of the desired size and shape. The coils provide a continuous supply of high-quality steel, ensuring the consistency and strength of the bolts produced.

- Q: What are the different grades of steel coils?

- There are several different grades of steel coils, including low carbon steel, medium carbon steel, high carbon steel, stainless steel, and galvanized steel. Each grade has its own unique properties and is used for specific applications based on factors such as strength, corrosion resistance, and formability.

- Q: What are the common methods of handling steel coils during production?

- The common methods of handling steel coils during production include using overhead cranes, forklifts, and coil tongs. These tools are utilized to lift, transport, and position the coils within the production facility. Additionally, coil cars and transfer systems are often used to move the coils between different stages of the production process. It is crucial to handle the steel coils with care to prevent damage and ensure efficiency in the production line.

- Q: I want to purchase a set of knives made of carbon steel and want to be able to store them on a magnetic knife strip for handy access, I just wasn't sure if this alloy would stick to a magnet????Thanks

- Carbon steel knives will stick to a magnet. Stainless steel may not.

- Q: What are the different methods of coil handling and storage?

- Various industries commonly employ several different methods for coil handling and storage to ensure safety, efficiency, and preservation. Some of these methods include: 1. Coil cradles: Popular for handling and storing coils, coil cradles feature a U-shaped structure that provides stability and support. The cradle is positioned beneath the coil and can be easily maneuvered using forklifts or overhead cranes. 2. Coil cars: Used for transporting coils within a facility or between locations, coil cars are equipped with specialized clamps or arms to securely hold the coil during transit. Manual or automatic operation is determined by coil size and weight. 3. Coil racks: Specifically designed storage systems for organized coil storage, coil racks are typically constructed from steel and feature multiple levels or compartments to accommodate various coil sizes and types. Forklifts or overhead cranes are used to access coil racks. 4. Coil turnstiles: In processing lines where continuous coil feeding into machines is required, coil turnstiles are employed. These rotating devices enable easy loading and unloading of coils by rotating them to the desired position, facilitating handling and processing. 5. Coil pallets: Specially designed pallets made of steel or wood, coil pallets are utilized for both storage and transportation of coils. Their unique configuration allows for convenient loading and unloading using forklifts or pallet jacks. Coil pallets are often utilized for long-distance transportation or warehouse storage. 6. Coil storage racks: Large storage systems designed for bulk coil storage, coil storage racks are typically made of steel and feature multiple levels or compartments to accommodate a significant number of coils. Forklifts or overhead cranes are utilized for accessing coil storage racks. These examples represent only a selection of the numerous coil handling and storage methods commonly employed across various industries. The specific method chosen depends on factors such as coil size and weight, available space, and industry-specific requirements.

Send your message to us

Chinese Best Hot-dip Zinc Coating Steel Building Roof Walls JIS G3302

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords