Hot-dip Zinc Coating Steel Building Roof Walls With Best Price Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls With Best Price Best Quality

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

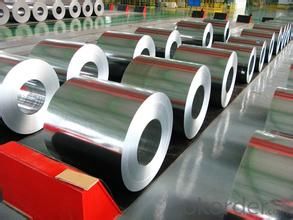

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: 3 bedroom rambler with attached garage. A bad hail storm in May damaged my white siding and roof. I am concerned insurance adjustThanks much.er will not give me replacement value for steel siding. Any one know the cost and where to buy in Minnesota.

- I'm not sure of the cost but from experience having bought steel siding instead of vinyl for my home, if you can afford the difference it is well worth your money..I've had it for 25 years and it does hold up much better than vinyl!

- Q: What are the advantages of using steel coils in construction?

- There are several advantages of using steel coils in construction. Firstly, steel coils are extremely strong and durable. They have a high tensile strength, which means they can withstand heavy loads and resist deformation. This makes them ideal for structural applications in construction, such as beams, columns, and frames. Secondly, steel coils are highly versatile. They can be easily shaped and molded into various forms, allowing for flexibility in design and construction. Steel coils can be rolled, bent, cut, and welded to meet specific project requirements. This adaptability makes them suitable for a wide range of construction applications. Another advantage of using steel coils in construction is their resistance to corrosion. Steel coils are often coated with protective coatings, such as galvanized or stainless steel, to prevent rusting and corrosion. This ensures that the structural integrity of the building remains intact over time, even in harsh environmental conditions. Furthermore, steel coils offer excellent fire resistance. Unlike other construction materials like wood, steel does not burn or contribute to the spread of fire. This makes it a safer choice for construction, particularly in high-rise buildings or areas prone to fire hazards. Lastly, steel coils are cost-effective. While the initial cost of using steel coils may be higher compared to some other materials, their longevity and low maintenance requirements make them a cost-efficient option in the long run. Steel coils have a long lifespan and require minimal repairs or replacements, resulting in reduced maintenance costs and increased overall value. In conclusion, the advantages of using steel coils in construction include their strength, versatility, corrosion resistance, fire resistance, and cost-effectiveness. These qualities make steel coils an excellent choice for various construction applications, contributing to the durability and safety of buildings.

- Q: How are steel coils used in the production of metal cladding?

- Steel coils serve as the primary raw material for metal cladding production. Metal cladding involves covering a building's exterior with a layer of steel to enhance its durability, aesthetics, and insulation. To begin the manufacturing process, galvanized steel coils are used. These coils are made by coating steel with zinc to prevent corrosion. They are then unrolled and fed into a roll-forming machine, which shapes them into the desired profile for the cladding panels. Once the coils are formed, they undergo various processes to improve their properties. These processes include cutting, perforating, and embossing to create patterns, textures, or openings in the panels. Additional protective layers, such as paint or powder coating, can also be applied to enhance corrosion resistance and appearance. The shaped and processed coils are assembled into metal cladding panels. These panels interlock seamlessly to create an appealing exterior for buildings. They can be attached to the building's structure using screws, clips, or adhesives. Using steel coils in metal cladding production offers several advantages. Steel is a strong and durable material, making it suitable for exterior applications that require resistance to weathering, impact, and other environmental factors. It also allows for a wide range of design options and customization. In summary, steel coils are essential in the production of metal cladding. They serve as the raw material, which is shaped, processed, and assembled into panels that enhance buildings' protection, aesthetics, and insulation properties.

- Q: could anybody tell me the the weight of a cubic metre of mild steel? and where to get this info from?

- Weight per meter kg/m kg/m = (Oc - 4Wt) * Wt * 0.00785 Oc = outside circuit, Wt = wall thickness For sq. steel tubes: Oc = 4*a For rect. steel tubes: Oc = 2a + 2b Specific Weight =7.85 g/cm3

- Q: What are the common coil packaging materials?

- Common coil packaging materials include plastic wrap, stretch film, steel strapping, and wooden crates. These materials are used to protect and secure coils during storage and transportation, ensuring they remain intact and undamaged.

- Q: Not sure if stainless steel is actually sealable but what's the best way to clean a brushed stainless steel appliance to not get so many finger prints...etc. I have stainless steel wipes that I used on another appliance and they don't work so great.

- Make a paste from Lemon Juice and salt, scrub gently, and then rinse with water. To clean a stainless steel surface, use mild detergent,or baking soda or vinegar diluted in water. Clean, then dry with a soft cloth. Most stainless steel has a grain; if you are using any kind of an abrasive on a stainless surface, always make sure you clean in the direction of the grain. The don'ts are: Don't use bleach. Don't use steel wool unless it is an absolute last resort. Some of the fine particles can lodge in the surface of the stainless and will eventually rust, giving the appearance that the stainless itself is rusting. Don't let the following food items (ketchup, mustard, mayonnaise, lemon juice, vinegar, salt, salad dressings) remain on your stainless surfaces for any length of time. If they sit on the stainless for more than a few minutes, they may bleach it out. You can actually rub out this white area with a very fine Scotchbrite pad. Make sure you are going along the grain lines and not at right angles to them.

- Q: How do steel coils contribute to the manufacturing of oil and gas equipment?

- Steel coils play a vital role in the production of oil and gas equipment, as they are an essential component. Typically, these coils are made from high-quality steel that is durable, strong, and resistant to corrosion. This makes them ideal for enduring the harsh environments and conditions encountered in the oil and gas industry. One of the primary uses of steel coils in oil and gas equipment manufacturing is in the creation of pressure vessels. These vessels are crucial for storing and transporting fluids and gases under high pressure. Steel coils are used to form the cylindrical shells of these vessels, providing the necessary strength and structural integrity to withstand the internal pressure. Steel coils are also utilized in the construction of oil and gas pipelines. These pipelines are responsible for transporting large quantities of oil and gas over long distances. Steel coils are used to manufacture the pipes that compose these pipelines, ensuring they have the necessary strength, durability, and resistance to corrosion. The coils are rolled and welded to create seamless or welded pipes, which are then coated or lined to prevent corrosion and increase their lifespan. Additionally, steel coils are instrumental in the production of drilling equipment used for extracting oil and gas. This equipment includes drill bits, casings, and wellheads, which are essential for drilling and completing wells. The coils are used to fabricate these components, ensuring they can withstand the demanding conditions encountered during drilling operations. Aside from their structural applications, steel coils are also used in the manufacturing of ancillary equipment like tanks, storage containers, and heat exchangers. These components play a crucial role in the processing, storage, and distribution of oil and gas. Steel coils provide the necessary strength and durability to handle the harsh conditions and corrosive substances encountered in these processes. In conclusion, steel coils are indispensable in the manufacturing of oil and gas equipment. Their strength, durability, and resistance to corrosion make them a preferred choice in the industry. By contributing to the fabrication of pressure vessels, pipelines, drilling equipment, and ancillary components, steel coils ensure the safe and efficient extraction, processing, and transportation of oil and gas.

- Q: How do steel coils contribute to energy savings in buildings?

- Steel coils contribute to energy savings in buildings by being used in various applications that help improve insulation and reduce heat transfer. They are commonly used in HVAC systems, where they act as heat exchangers, transferring heat between air streams. Steel coils with high thermal conductivity ensure efficient heat transfer, allowing for effective cooling or heating of air without excessive energy consumption. Additionally, steel coils are utilized in the construction of insulated walls and roofs, forming an integral part of the building envelope. This helps minimize thermal bridging, preventing heat loss or gain through the building's structure. By improving insulation and reducing energy transfer, steel coils play a crucial role in enhancing the overall energy efficiency of buildings, leading to significant energy savings.

- Q: So...I'm learning about how steel is made and I'm wondering if there is a more environmentally friendy method. I view it as unfriendly b/c of the oxygen that is injected when the steel is in the blast furnace or electric arc furnace. This oxygen bonds w/ the carbon to produce CO and CO2. THis is necessary to reduce the amount of carbon content to produce harder steels. So what other methods are there that can be used w/o having to end up w/ co and co2? thanks

- From what I understand of it, US steel is better as the steel is more recycled than Canadian, so a lot of that oxygen / CO2 has already taken place compared to working from ore. The second reason US steel is environmentally ahead of Canadian is that US tends to use Electric Arc, while Canadian uses Basic Oxygen, Basic Oxygen uses more energy than electric arc, and I think it also uses more oxygen, but I would suspect that oxygen that it uses is 'waste oxygen' and not converted into Co2 because the Co2 process is limited by the carbon, and steel only has so much carbon.

- Q: How are steel coils inspected for surface defects using non-destructive testing methods?

- Steel coils are inspected for surface defects using non-destructive testing (NDT) methods to ensure their quality and integrity. There are several common NDT methods employed in this process. One of the most widely used methods is visual inspection, where trained inspectors visually examine the surface of the steel coils for any visible defects such as scratches, cracks, pits, or corrosion. This method is relatively simple and cost-effective but is limited to detecting only surface-level defects. Another commonly used NDT method is magnetic particle testing (MT). This method utilizes the principles of magnetism to identify surface and near-surface defects in ferromagnetic materials like steel. A magnetic field is applied to the steel coil, and iron particles are applied to the surface. If there is a defect, such as a crack or discontinuity, the iron particles will concentrate around it, making the defect visible to the inspector. Liquid penetrant testing (PT) is another NDT method used to inspect steel coils for surface defects. In this method, a liquid penetrant is applied to the surface of the coil. The penetrant is drawn into any surface defects by capillary action. After a certain period, excess penetrant is removed, and a developer is applied. The developer draws out the penetrant from any defects, making them visible to the inspector. Ultrasonic testing (UT) is a widely used NDT method that can detect both surface and subsurface defects in steel coils. High-frequency sound waves are transmitted into the steel coil, and the reflected waves are analyzed to identify any abnormalities. This method can detect defects such as cracks, inclusions, and voids that may not be visible to the naked eye. Additionally, eddy current testing (ECT) is another NDT method used for inspecting steel coils. This method utilizes electromagnetic induction to detect surface and near-surface defects. A coil carrying an alternating current is placed near the surface of the coil being inspected. Any changes in the coil's electrical conductivity caused by surface defects are detected and analyzed, allowing the inspector to identify and evaluate the severity of the defects. In conclusion, steel coils are inspected for surface defects using various non-destructive testing methods such as visual inspection, magnetic particle testing, liquid penetrant testing, ultrasonic testing, and eddy current testing. These methods ensure the quality and integrity of the steel coils before they are used in various applications.

Send your message to us

Hot-dip Zinc Coating Steel Building Roof Walls With Best Price Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords