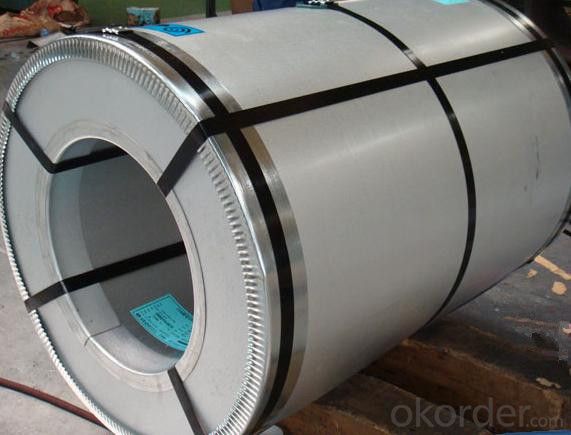

Zinc Coated Gi Galvanized Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:roofing sheet

Surface Treatment:Galvanized

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS, GOST

Steel Grade:Q235

Grade:Dx51d / Dx52d/ Dx53D/ S250,280,320gd

Width:914, 1000, 1200, 1219, 1220, 1250

Base Material:Galvanized or Gavalume, Steel

Thickness:0.14mm to 1.5mm

Zinc Coating:40-150GSM

Length:up to The Thickness

Lacquer:Top Side15-25 Micro,Back Side 5 Micro

Surface:Passivation Unoiled Free Spangle Passivated

Export Markets:Global

Additional Info.

Trademark:STW or OEM

Packing:Export Seaworthy Packing

Standard:According to Your Requirement

Production Capacity:20000 Metric Tons/Month

Product Description

Specifications;

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight:4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 30000MT/month

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 30 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

| MOQ | 50MT |

| What knid of color we can offer | RAL not only RAL, we can provide the color according to customer' s sample |

| What is the paint? | PE, PVDF |

| What is the original material for color-coated coil? Galvanized steel coil/cold rolled coill? | PPGI(raw material GI), GI(raw material CRC) CRC( raw material HRC) |

| Surface | Regular/mini/zero spangle, chromated, skin pass, dry etc. |

| Coil Inner Diameter | 508mm |

| Strength of material ? | G550= 550 mpa, normally around 280 mpa |

| what is the range of width we can do | 750mm, 762mm, 914mm, 1000mm, 1200mm, 1219mm, 1220mm, 1250mm |

| Thickness of the zinc coating | Z40 to Z275 |

| which color is most popular? | Blue in China, brown, red, green in oversea market |

| The weight of each coils? | Normally 5Tons. We can customized 3-6Tons |

| What is the leadtime? | Normally for coils we can delivery it within 25-30 days. Depends on the quantity |

| How many years of the paint would be lasting? | Different zinc, paint coating would lead to different result, and the environment has great impact on the life time of painting. |

| Applications | With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect. |

- Q: What is the maximum width of a steel coil?

- The maximum width of a steel coil can vary depending on the specific manufacturing capabilities and equipment being used. However, in general, steel coils can have widths ranging from a few inches to several feet.

- Q: There's this huge community of steelians (steelites?) in my town. Has anybody heard of this Dr. Steel?

- Here are twenty that I grew up listening to, such a lot of them within the loved ones auto in which I had 0 manage over what used to be performed. But I nonetheless love each one in every of them to nowadays... Sea Cruise- Frankie Ford Walk Don't Run- The Ventures Don't Worry Baby- The Beach Boys Bus Stop- The Hollies These Boots Are Made For Walking- Nancy Sinatra I Saw Her- Mamas Papas A Taste Of Honey- Herb Alpert Everybody's Talking At Me- Nilsson Superstar- The Carpenters Indian Reservation- Paul Revere The Raiders Come And Get It- Badfinger Tell Me Something Good- Rufus Come And Get Your Love- Redbone Higher Ground- Stevie Wonder Waterloo- ABBA How Long (Has This Been Going On)- Ace The Hustle- Van McCoy More More More- Andrea True Connection Shining Star- Earth, Wind Fire Got To Give It Up- Marvin Gaye

- Q: a concrete or steel building?also, what is the density of concrete and steel? is concrete heavier in steel for the same volume?

- The denisty of reinforced concrete is taken to be 150 lbs/ft^3 The density of carbon structural steel is 490 lbs/ft^3

- Q: Im going to buy T-304 Stainless Steel exhaust tips for my truck. Is T-304 Stainless Steel good metal?

- Stainless steel is available in 2 grades - 304 and 316. The 304 has traces of ferrous to make it adaptable for the intended purpose. The 316 is non-ferrous and a bit more expensive. Whereas the 316 will not inhibit rust, the 304 will show some flecks (which can be cleaned away) over a period of time. It, however, is as good as the other.

- Q: What are the common surface treatments for steel coils?

- The common surface treatments for steel coils include galvanization, which involves coating the steel with a layer of zinc to protect against corrosion, as well as painting or powder coating to provide additional protection and enhance aesthetics.

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear slitting, loop slitting, and oscillating slitting.

- Q: Can steel coils be customized in terms of size and thickness?

- Yes, steel coils can be customized in terms of size and thickness. Manufacturers have the capability to produce steel coils in various sizes and thicknesses to meet the specific requirements of different industries and applications.

- Q: Which movie is better and why?I say Man of Steel!

- Captain America: The First Avenger -- Mostly because it was a rousing, entertaining, old-school adventure film, plus it was true to the character of Steve Rogers/Captain America. Man of Steel, IMO, had a poor script, tinkered way too much with one of the great superhero origin stories and was not at all true to the character. Historically Superman has always been a symbol of heroism, proud, strong, beaming. But what we got in that movie was an utterly cheerless, dour automaton devoid of any kind of charisma or presence. I don't know who that boring, depressed dude who looked like Superman was in that movie, but he most certainly wasn't Superman.

- Q: How are steel coils used in the manufacturing of wires?

- Steel coils are used in the manufacturing of wires by being fed into wire drawing machines where they are elongated and reduced in diameter to the desired thickness. The steel coils provide a continuous supply of raw material, ensuring a seamless production process for manufacturing wires of various sizes and applications.

- Q: How are steel coils used in the manufacturing of drivetrains?

- Steel coils are used in the manufacturing of drivetrains as they are commonly used to create various components such as gears, shafts, and bearings. These coils are typically processed and shaped into the required forms through cutting, molding, and heat treatment. The steel's strength and durability make it ideal for withstanding the high stresses and forces experienced in drivetrain systems, ensuring reliable and long-lasting performance.

Send your message to us

Zinc Coated Gi Galvanized Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords