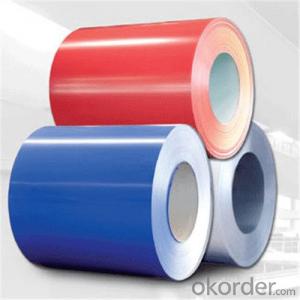

Hot Dipped Prepainted Galvanized Steel Coils/Prepainted Cold Rolled Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

Product Description

CONTENTS | PRODUCT SPECIFICATION | |||||

| Commodity | Prepainted galvanized steel coil | |||||

| Base Metal | Cold rolled, Electro-galvanized base metal, Hot-dip zinc coated base metal, Hot dip Al-Zn steel sheet | |||||

Thickness | 0.16 TO 1.00 mm | |||||

| Width | 600 TO 1500 mm | |||||

| Coil ID | 508 / 610 mm | |||||

| Type | coil/sheet/strips | |||||

Delivery Time | 15-30days after we receive deposit | |||||

Substrate Hardness | Soft, medium,full hard | |||||

| Zinc Coating | Z 40-275 gsm, AZ 40-180 gsm or as customer requirements | |||||

| Types of top coating | PE, Silicon modified polyesters, High-durability polyester, polyvinylidene fluoride | |||||

Colours | As per RAL shades/customer requirements. | |||||

| Surface Finishes | Glossy and Matte | |||||

| Price: | US $600-800 / Metric Ton | |||||

| Slits | 37mm and above | |||||

| Standards | AISI, ASTM, BS, DIN, GB, JIS | |||||

| Transport | By bulk or container | |||||

| Packing | Standard packing or at buyer's requirement | |||||

Applications:

Pre-painted steel metal products are used in a vast array of applications including:

1.construction industry

2. household appliances

3.automotive

4.industrial applications

5.packaging

FAQ

What is the validity of your quotation?

Normally 2 days.

- Q: How are steel coils used in the production of steel fasteners?

- Steel coils are used in the production of steel fasteners as they serve as the raw material for manufacturing various types of fasteners such as screws, bolts, nuts, and washers. The steel coils are unwound and then processed through machinery that cuts, shapes, and forms them into the desired fastener shape. This allows for efficient and precise production of steel fasteners, ensuring their strength, durability, and compatibility with various applications.

- Q: Can steel coils be welded together?

- Indeed, it is possible to weld steel coils together. The practice of welding is widely employed in the fusion of metals, including steel coils. It entails the melting of the coil edges and their subsequent amalgamation with a filler material. This procedure generates a sturdy and long-lasting bond between the coils, enabling their unification into a singular entity. The act of welding steel coils together is frequently carried out across a range of industries, such as manufacturing, construction, and automotive, in order to fabricate larger structures or components. However, it is crucial to adhere to proper welding techniques and implement stringent quality control measures to guarantee the integrity and potency of the weld joint.

- Q: I have been searching on pots and pans, how can I find out if it's really stainless steel, someone told me if a magnet sticks to it it's real stainless steel is this true?

- Some types of stainless are magnetic and some are not. being magnetic isn't a reliable way to tell the difference. In fact, only the cheapest pots would be made out of grades of stainless that are magnetic. Stainless pots/pans are generally made of non-magnetic types, but then again, aluminum isn't magnetic either. Aluminum and stainless are superficially very similar.

- Q: How are steel coils handled during loading and unloading?

- Steel coils are typically handled using specialized equipment such as cranes or forklifts during loading and unloading. They are carefully lifted, secured, and positioned onto trucks or storage areas. Safety measures are followed to prevent damage or accidents during the process.

- Q: What are the advantages of using steel coils in construction?

- Using steel coils in construction offers several advantages. Firstly, they possess immense strength and durability, enabling them to withstand heavy loads and resist deformation. As a result, they are perfect for structural purposes such as beams, columns, and frames. Secondly, steel coils exhibit exceptional versatility. They can be easily shaped and molded into various forms, providing flexibility in design and construction. Steel coils can be rolled, bent, cut, and welded according to specific project requirements. This adaptability makes them suitable for a wide range of construction applications. Another benefit of utilizing steel coils in construction is their resistance to corrosion. To prevent rusting and corrosion, steel coils are often coated with protective substances like galvanized or stainless steel. This ensures that the building's structural integrity remains intact over time, even in harsh environmental conditions. Furthermore, steel coils offer excellent fire resistance. Unlike materials such as wood, steel does not burn or contribute to the spread of fire. Hence, it is a safer option for construction, especially in high-rise buildings or areas prone to fire hazards. Lastly, steel coils are cost-effective. Although the initial cost of using steel coils may be higher compared to other materials, their longevity and low maintenance requirements make them a cost-efficient choice in the long run. Steel coils have a long lifespan and necessitate minimal repairs or replacements, resulting in reduced maintenance costs and increased overall value. In conclusion, the advantages of using steel coils in construction encompass their strength, versatility, corrosion resistance, fire resistance, and cost-effectiveness. These qualities make steel coils an outstanding choice for various construction applications, contributing to the durability and safety of buildings.

- Q: Are steel coils used in electrical equipment manufacturing?

- Yes, steel coils are commonly used in electrical equipment manufacturing. Steel coils are often used as core material in transformers, motors, and generators due to their magnetic properties and ability to efficiently transfer electrical energy. They provide structural support and help enhance the performance and efficiency of electrical equipment.

- Q: What are the different types of steel coil slitting techniques?

- There are several types of steel coil slitting techniques, including rotary slitting, loop slitting, and oscillating slitting. Rotary slitting involves using circular blades to cut the steel coil into narrower strips. Loop slitting involves creating a loop in the steel coil and then cutting it with straight blades. Oscillating slitting uses a reciprocating blade that moves back and forth to cut the coil into smaller widths.

- Q: What are the different surface finishes of steel coils?

- There are several different surface finishes of steel coils, including hot rolled, cold rolled, galvanized, and coated finishes. Hot rolled coils have a rough and textured surface, while cold rolled coils have a smoother and more refined surface. Galvanized coils are coated with a layer of zinc to protect against corrosion, while coated coils have additional layers of paint or other materials for aesthetic or functional purposes.

- Q: How are steel coils inspected for camber?

- To ensure the quality and suitability of steel coils for further processing, various methods are employed to inspect their camber. One commonly used approach is visual inspection, where trained inspectors carefully examine the coils for any visible indications of camber. They search for any deviations from a perfectly straight surface, such as bows or curves, which serve as signs of camber. Another method involves the use of specialized equipment, including straightedges, measuring tapes, and laser devices. Inspectors place the straightedge along the length of the coil to assess any gaps or spaces between the coil and the straightedge. If a significant deviation is detected, it signifies the presence of camber. Measuring tapes are also utilized to measure the distance between the coil and the straightedge at multiple points along its length. This enables inspectors to ascertain the extent of camber and determine if it falls within acceptable tolerance limits. In some cases, laser devices are employed to provide a more precise measurement of camber. These devices emit a laser beam that reflects off the surface of the coil and is subsequently analyzed to determine the presence and magnitude of camber. Furthermore, advanced technologies such as computer vision systems and artificial intelligence algorithms are now being integrated into the inspection process. These technologies have the capability to analyze images or videos of the steel coils and automatically detect any camber, thereby delivering accurate and efficient inspection results. In conclusion, the inspection of steel coils for camber involves a comprehensive approach that combines visual inspection, manual measurements using straightedges and measuring tapes, and the utilization of advanced technologies. This multifaceted approach ensures effective detection and control of camber, thereby upholding the quality and integrity of the steel coils.

- Q: I know that carbon steels and alloy steels are different but are carbon steels still alloys?Thanks!

- Carbon steel, or plain-carbon steel, is a metal alloy. It is a combination of two elements, iron and carbon. Depending upon the amount of presence of carbon in the alloy, Carbon steel can be classified into 4 different categories- Low Carbon Steel Medium Carbon Steel High Carbon Steel Very High Carbon Steel

Send your message to us

Hot Dipped Prepainted Galvanized Steel Coils/Prepainted Cold Rolled Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords