The Cheap Hot-dip Zinc Coating Steel Building Roof Walls JIS G3302

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

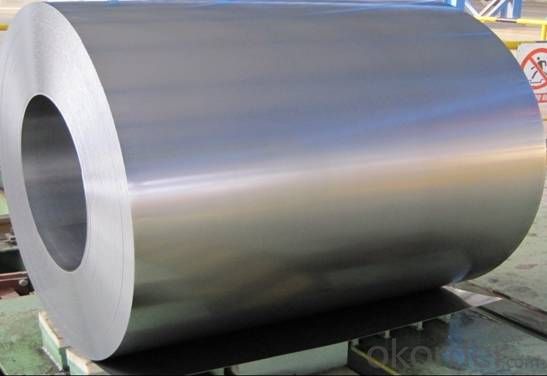

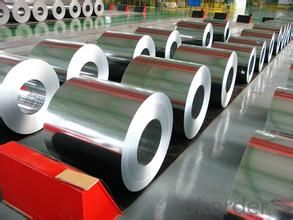

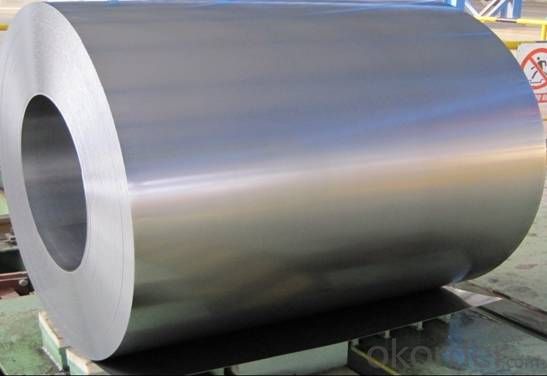

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

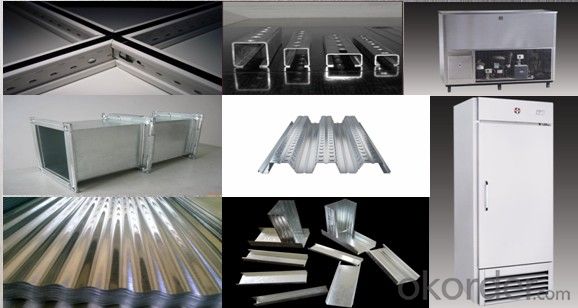

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What is the width range of steel coils?

- The width range of steel coils can vary depending on the specific requirements and industry standards, but generally, it can range from a few millimeters to several meters.

- Q: Brass as a rule I believe is betterhowever I do not plan to get into reloading any time soon I just want some cheap practice ammo so will steel case ammo hurt my gun (semi auto) any more than brass ammo and if so how much more?

- Depends what your gun is. I wouldn't shoot steel through a 5,000 dollar gun but my SKS jams up with anything except steel ammo. It adds wear to some guns but in most cases you won't shoot enough to cause any real problems. They also make steel that is coated in lacquer that protects your gun a little. In most cases steel is no big deal, in high performance weapons I would say no.

- Q: Is it just because brass is reloadable? But what makes it reloadable? What does brass bring to the equation that the steel cased ammo can't do?

- Steel okorder /

- Q: What are the different methods of engraving steel coils?

- There are several different methods of engraving steel coils, each with its own advantages and applications. Some of the most common methods include: 1. Chemical Etching: This is a process that involves applying a chemical solution to the surface of the steel coil, which selectively removes the metal to create the desired design. Chemical etching is highly precise and can produce intricate patterns and fine details. It is commonly used for decorative purposes, such as creating logos or patterns on steel coils. 2. Laser Engraving: Laser engraving uses a high-powered laser beam to remove the top layer of the steel coil, creating a permanent mark. This method offers high precision and allows for the engraving of complex designs, logos, or text. Laser engraving is frequently used for branding purposes or to add identification marks to steel coils. 3. Mechanical Engraving: Mechanical engraving involves the use of a cutting tool or a diamond-tipped stylus to physically remove the metal from the steel coil's surface. This method is known for its durability and versatility, as it can create deep and long-lasting engravings. Mechanical engraving is often used for industrial applications, such as adding serial numbers, part codes, or other identification marks to steel coils. 4. Electrochemical Etching: Electrochemical etching, also known as electrolytic etching, utilizes an electric current to selectively dissolve the metal surface of the steel coil. This technique is commonly used for marking and branding purposes, as it can produce high-quality, permanent engravings. Electrochemical etching is often employed in industries where precision and durability are essential, such as aerospace or automotive manufacturing. 5. Inkjet Printing: While not strictly engraving, inkjet printing is a method that can be used to add patterns or designs onto steel coils. This process involves using specialized inks and a digital printing system to apply the desired design directly onto the surface of the coil. Inkjet printing is versatile, cost-effective, and allows for high-resolution prints, making it suitable for various applications, including decorative or branding purposes. In conclusion, the different methods of engraving steel coils offer a range of options for creating permanent markings, logos, or patterns. The choice of method depends on factors such as the desired level of precision, durability requirements, and the specific application for the steel coil.

- Q: Fallout 3 take it back quest?if i am in the rotunda and dont have broken steel installed yet so i cant leave if i instal it will i be able to continue the game even if im seconds away from the end without it Additional Detailsi know it continues on but im not sure if it will let me cause i got this far without it 1 objective away from finishing the quest idk if it will change that little bit so i can continue (ps3)already in the purifier place kill col. autum liek i said just gotta do the code thing to it idk if im to far for broken steel to effect this save file

- Yes. The Broken Steel add-on goes automatically where ever you are. The thing is, I would like stand around the control room for a little while until the Broken Steel add-on is completely downloaded (Basically pop A LOT of rad-x and radaway). You should see a pop-up message saying that Broken Steel is installed and the level cap is now at 30.

- Q: What are the common methods of protecting steel coils from corrosion during storage?

- To safeguard steel coils from corrosion during storage, there are multiple commonly employed techniques. These methods aim to shield the steel coils from moisture and other environmental factors that could trigger corrosion. 1. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging is extensively utilized for steel coil protection. It incorporates VCI materials into the packaging, such as plastic bags or films. These materials emit a vapor that forms a protective layer on the surface of the steel coils, effectively preventing the intrusion of moisture and corrosive agents. 2. Oil Coating: Another widely adopted approach involves applying a thin layer of oil onto the steel coil surface. This oil acts as a barrier, obstructing the contact between the steel and moisture or oxygen. It proves particularly effective for long-term storage or transportation situations. 3. Desiccants: Silica gel packets or similar desiccants can be placed inside the packaging to absorb any trapped moisture. By reducing humidity levels within the packaging, the risk of corrosion is minimized. This method is often combined with VCI packaging or oil coating. 4. Proper Ventilation: Adequate ventilation is crucial to prevent moisture buildup around the steel coils during storage. By facilitating the free circulation of air, humidity levels are reduced, and the formation of condensation, which can lead to corrosion, is prevented. 5. Controlled Environment: Storing steel coils in a controlled environment is an effective corrosion prevention measure. This entails maintaining constant temperature and humidity levels that are unfavorable for corrosion. Temperature and humidity control can be achieved using air conditioning or dehumidification systems. It should be noted that the choice of specific protection methods or combinations thereof depends on various factors, including storage duration, environmental conditions, and specific steel coil requirements. Regular inspections and maintenance are also vital to ensure ongoing corrosion protection.

- Q: How are steel coils used in the manufacturing of marine equipment?

- Steel coils are commonly used in the manufacturing of marine equipment as they provide a strong and durable material for various applications. These coils are often shaped, cut, and formed into different components such as hulls, propeller shafts, and structural supports. The high tensile strength of steel coils ensures the equipment's ability to withstand the harsh conditions of marine environments, including corrosion and pressure from waves and currents. Additionally, steel coils can be easily welded, making them suitable for constructing larger structures like ship decks and bulkheads.

- Q: What website can I use to find a good picture that shows the atomic structure of a carbon steel?

- This Site Might Help You. RE: Where can I find an atomic structure of carbon steel? What website can I use to find a good picture that shows the atomic structure of a carbon steel?

- Q: How are steel coils used in the production of household appliances?

- Steel coils are used in the production of household appliances as the primary material for manufacturing various components, such as the outer body, frames, and structural parts. The coils are first shaped, cut, and formed into specific sizes and shapes, depending on the appliance being produced. These steel components provide strength, durability, and stability to the appliances, ensuring longevity and resistance to wear and tear.

- Q: Can steel coils be used in the production of automotive parts?

- Yes, steel coils can be used in the production of automotive parts. Steel coils are often used in the manufacturing process of various automotive components such as body panels, frames, chassis, suspension parts, and engine parts. The steel coils are typically processed through various methods such as cutting, stamping, bending, and welding to shape them into the desired automotive parts. Steel is a preferred material for automotive parts due to its strength, durability, and resistance to corrosion. Moreover, steel coils are available in different grades and thicknesses, allowing manufacturers to tailor the material properties to meet specific requirements for different automotive applications. Overall, steel coils play a critical role in the production of automotive parts, contributing to the performance, safety, and longevity of vehicles.

Send your message to us

The Cheap Hot-dip Zinc Coating Steel Building Roof Walls JIS G3302

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords