Cheap Steel Structure Warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

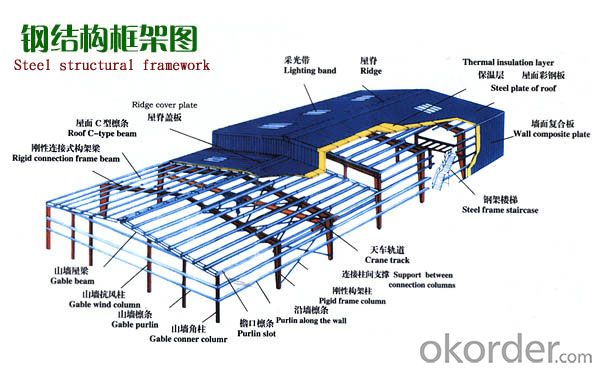

Steel Structure

We can design,fabricate and install all kinds of steel structure buildings.

Item Name: Steel Structure

Size: Length,Width and height according to customer's requirements.

Material: Q235 and Q345.

Surafce: hot dip galvanize or Painted

Drawings: We can make the quotation according to customer's drawing.

We can also make the design and quotation according to customer's requirements.

We can offer all the detailed drawings for installation and fabrication.

Packing: Decided by buyer.

Load in to 40ft GP,20ft GP or 40HQ or 40OT.

Carbon structural steel: Q195, Q215, Q235, Q255, Q275, etc.

High-strength low-alloy structural steel

Quality carbon structural steel and alloy structural steel

Special purpose steel

- Q: What are the aesthetic possibilities of steel structures?

- The aesthetic possibilities of steel structures are vast and diverse. Steel's strength and flexibility allow for innovative and unique architectural designs, ranging from sleek and minimalist to intricate and ornate. Its ability to be molded and shaped into various forms opens up endless possibilities for creating visually stunning structures. Steel can be treated with different finishes and coatings, giving it a wide range of colors and textures. Additionally, steel structures can incorporate elements such as glass, wood, and other materials, further enhancing their aesthetic appeal. Overall, the aesthetic possibilities of steel structures are limited only by imagination and creativity.

- Q: What are the considerations for steel structure design in arctic climates?

- Designing steel structures for arctic climates requires careful consideration of several factors to ensure durability and safety in these extreme conditions. 1. Temperature: Arctic climates experience extremely low temperatures, sometimes dropping below -50°C. Steel structures should be designed to withstand these extreme temperatures without undergoing brittle fracture or excessive thermal expansion. Materials with high fracture toughness and low temperature resistance, such as low alloy steels, are often used. 2. Frost heave: In arctic regions, the ground freezes and thaws repeatedly, leading to frost heave. This can cause significant movement and deformation of the foundation and structure. Engineers must design the foundations to mitigate the effects of frost heave, often by using deep foundations or insulation to prevent heat transfer from the structure to the ground. 3. Snow and ice loads: Heavy snowfall and ice accumulation are common in arctic regions. The design of steel structures should account for these loads to ensure the structure can safely support them. Designers need to consider the weight, shape, and distribution of snow and ice on the structure, as well as the potential for drifting and sliding. 4. Wind loads: Arctic climates often experience strong winds, especially in coastal areas. Steel structures must be designed to withstand these high wind speeds by considering wind loads, wind pressures, and the potential for wind-induced vibrations. Adequate bracing, connections, and wind-resistant shapes are essential to ensure structural stability. 5. Corrosion protection: Arctic climates have high humidity levels and exposure to saltwater in coastal areas, increasing the risk of corrosion. Steel structures should be protected against corrosion through the use of appropriate coatings, such as galvanization or specialized paints. Regular maintenance and inspections are also necessary to prevent or address any corrosion issues. 6. Thermal insulation: To minimize heat loss and energy consumption, steel structures in arctic climates require effective thermal insulation. Insulation materials and systems should be carefully chosen to prevent condensation, reduce heat transfer, and maintain comfortable indoor temperatures. 7. Construction logistics: Building in remote arctic areas can present logistical challenges due to limited transportation, harsh weather conditions, and a scarcity of local resources. Designers must consider these factors when selecting construction methods, materials, and equipment to ensure the feasibility and efficiency of the construction process. Overall, designing steel structures for arctic climates requires a comprehensive understanding of the unique environmental conditions and their impact on the structural integrity. Proper consideration of temperature, frost heave, snow and ice loads, wind loads, corrosion protection, thermal insulation, and construction logistics is crucial for ensuring safe and durable steel structures in these extreme environments.

- Q: How long do steel structures typically last?

- Steel structures typically last for several decades, often ranging from 50 to 100 years, depending on various factors such as maintenance, environmental conditions, and usage.

- Q: How are steel structures designed for resisting earthquake-induced ground settlements?

- To resist ground settlements caused by earthquakes, steel structures are engineered with specific design considerations and techniques. The main objective is to guarantee the structure's ability to withstand the potentially destructive effects of ground settlements during seismic events. Flexibility is a key factor in the design process. By allowing the steel structure to flex and deform in response to seismic forces, it can effectively absorb and distribute the energy produced by ground settlements. This is accomplished by using ductile materials and carefully calculating the connections between steel members. Furthermore, the structural design incorporates seismic-resistant systems, such as base isolation or energy dissipation devices. Base isolation involves placing the structure on flexible bearings or isolators, which separates it from the ground and minimizes the transmission of ground settlements to the building. Energy dissipation devices, such as dampers or braces, are also installed to absorb and dissipate seismic energy, further lessening the impact of ground settlements. In addition, steel structures are designed with redundancy and robustness in mind. Multiple load paths and redundant elements ensure that even if one part of the structure is affected by ground settlements, the overall stability of the building remains intact. This allows the structure to endure localized settlements without compromising its overall integrity. Advanced computational models and simulation techniques play a crucial role in the design process. These models take into account factors such as anticipated ground motion, soil properties, and the specific characteristics of the steel members and connections. By analyzing the structure's response to various ground settlement scenarios, engineers can optimize the design to enhance its seismic performance. Overall, the design of steel structures to resist earthquake-induced ground settlements involves a combination of flexibility, seismic-resistant systems, redundancy, and robustness. These design considerations, along with the utilization of advanced analysis techniques, ensure that the structure is capable of withstanding the dynamic forces generated by ground movements during an earthquake.

- Q: How do steel structures meet building code requirements?

- Steel structures are able to meet building code requirements due to their inherent strength and durability. Building codes are established by regulatory bodies to ensure the safety and integrity of structures, and steel has proven to be a reliable and compliant material. Firstly, steel structures are designed and engineered by professionals who adhere to building codes and standards. These codes outline specific requirements for factors such as load-bearing capacity, fire resistance, seismic resistance, and wind resistance. Steel's high strength-to-weight ratio allows for efficient structural designs that meet or exceed these requirements. Secondly, steel undergoes rigorous testing and quality control measures to ensure its consistency and performance. The manufacturing process involves precise fabrication techniques, such as welding and bolted connections, that meet the code's specifications. Additionally, steel components are often subjected to non-destructive testing methods, including ultrasonic testing, magnetic particle inspection, and visual inspections to detect any flaws or defects. Steel structures also benefit from their ability to adapt to changing building code requirements. As building codes evolve and become more stringent, steel provides the flexibility to incorporate new design techniques and technologies. For example, steel structures can be easily retrofitted to improve their resistance against earthquakes or to enhance their energy efficiency. Furthermore, steel structures offer several advantages that align with building code requirements. Steel is non-combustible, which helps in meeting fire safety regulations. It is also resistant to termites, rot, and decay, ensuring the longevity and structural integrity of the building. Moreover, steel's high recyclability makes it an environmentally-friendly choice that aligns with sustainable building practices, which are increasingly becoming part of building codes. In conclusion, steel structures meet building code requirements through their strength, durability, and compliance with engineering standards. The use of steel in construction allows for efficient designs, precise fabrication, and adherence to various safety regulations. With its ability to adapt to evolving codes and its inherent advantages, steel remains a reliable and popular choice for meeting building code requirements.

- Q: What are the requirements for fire protection in steel structures?

- The requirements for fire protection in steel structures typically include the use of fire-resistant materials such as fire-rated coatings, sprays, or intumescent paints applied to the exposed steel surfaces. These materials help to limit the temperature rise of the steel during a fire, preventing structural failure. Additionally, fire protection measures may also involve the installation of fire-resistant barriers, such as fire-resistant walls or ceilings, to compartmentalize the building and prevent the spread of fire. The specific requirements for fire protection in steel structures may vary depending on local building codes and regulations.

- Q: What are the considerations for designing steel curtain wall systems?

- When designing steel curtain wall systems, there are several considerations that need to be taken into account. These considerations include structural integrity, thermal performance, water and air infiltration, aesthetics, and ease of installation and maintenance. Firstly, the structural integrity of the steel curtain wall system is crucial. The design should ensure that it can withstand wind loads, seismic activity, and other external forces. The strength and stability of the steel framing and connections must be carefully calculated and engineered to provide a safe and durable structure. Secondly, thermal performance is an important consideration. Steel has a high thermal conductivity, so measures must be taken to minimize heat transfer through the curtain wall system. This can be achieved by using thermal breaks, insulating materials, and double-glazed or low-emissivity glass. Proper insulation is necessary to prevent energy loss and maintain a comfortable indoor environment. Water and air infiltration are other considerations when designing steel curtain wall systems. The design should incorporate weather barriers and sealants to prevent water leakage and air infiltration. This requires careful attention to the joints, connections, and transitions between different materials to ensure a watertight and airtight system. Aesthetics also play a crucial role in the design of steel curtain wall systems. The appearance of the curtain wall should complement the overall architectural design and contribute to the desired aesthetic appeal. The selection of finishes, colors, and glazing options should be considered to achieve the desired visual effect. Lastly, ease of installation and maintenance should be considered. Steel curtain wall systems should be designed for efficient installation, minimizing time and cost. Additionally, the design should allow for easy access and maintenance of the system, such as cleaning, repairs, and replacement of components. Overall, designing steel curtain wall systems requires careful consideration of structural integrity, thermal performance, water and air infiltration, aesthetics, and ease of installation and maintenance. By addressing these considerations, architects and engineers can create a functional and visually appealing curtain wall system that meets the needs and requirements of the project.

- Q: How are steel structures used in military and defense facilities?

- Military and defense facilities heavily rely on steel structures due to their unique properties that make them perfect for the demanding requirements of such establishments. Military hangars and aircraft maintenance facilities are one key application for steel structures. These structures create a secure and controlled environment for storing and maintaining military aircraft, protecting them from harsh weather conditions and potential threats. Additionally, steel structures are used in constructing command centers, barracks, and other administrative buildings. These buildings need a strong and durable framework to withstand potential attacks and provide a safe working environment for military personnel. Steel is also used in building ammunition storage facilities and armories. Its strength and fire resistance properties ensure the safety and security of stored munitions, minimizing the risk of accidents or unauthorized access. Furthermore, steel structures play a vital role in constructing military training facilities. These facilities often require large open spaces, which can be efficiently achieved using steel structures. Steel allows for large spans and column-free spaces, enabling flexibility for various training activities like obstacle courses, shooting ranges, and combat simulations. Another important application of steel structures in military and defense facilities is in constructing border checkpoints and security infrastructure. Steel barriers, fences, and gates are utilized to fortify perimeters and control access points, improving security and preventing unauthorized entry. In conclusion, the use of steel structures in military and defense facilities guarantees the necessary strength, durability, and security to protect personnel, equipment, and strategic assets. The versatility and structural integrity of steel make it an indispensable material in constructing these essential facilities.

- Q: How are steel structures used in power plants and industrial facilities?

- Due to their durability, strength, and versatility, steel structures find extensive use in power plants and industrial facilities. In power plants, these structures serve various purposes in supporting the heavy machinery and equipment necessary for power generation. Boilers, turbines, generators, and cooling towers are commonly constructed using steel frameworks due to its high load-bearing capacity, enabling them to withstand the immense weight and stress exerted by these components. Furthermore, steel structures are also employed in power plant buildings such as control rooms, administration offices, and storage facilities. These structures provide a stable and secure environment for personnel, equipment, and important documents. The fire-resistant properties of steel are particularly valuable in power plants as they help mitigate the risk of fire hazards. Likewise, in industrial facilities, steel structures play a crucial role in supporting heavy manufacturing equipment, conveyors, and overhead cranes. They offer a stable platform for machinery operation, ensuring safety and efficiency. Additionally, steel structures are frequently used in the construction of warehouses, workshops, and production areas, allowing for spacious open spaces and adaptable layouts to accommodate various industrial processes. Moreover, steel structures provide numerous advantages in power plants and industrial facilities. They exhibit high resistance to corrosion, a vital characteristic in environments where exposure to chemicals, moisture, and harsh conditions is common. Additionally, steel structures boast a long lifespan, reducing the need for frequent maintenance and replacement. In conclusion, steel structures are indispensable in power plants and industrial facilities due to their ability to provide necessary support, durability, and versatility for heavy machinery and equipment. They ensure the safety, efficiency, and long-term functionality of these facilities, making steel an essential material in the power and industrial sectors.

- Q: What are the different types of steel footings used in construction?

- There are several types of steel footings commonly used in construction, including spread footings, strip footings, pile footings, and drilled pier footings.

Send your message to us

Cheap Steel Structure Warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords