Carbon Steel Universal Beam in I Shaped Form Chinese Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Carbon Steel Universal Beam in I Shaped Form Description:

Carbon steel universal beam in I shaped form is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Carbon steel universal beam in I shaped form is usually made of structural steel and is used in construction and civil engineering. The carbon steel universal beam in I shaped form resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Carbon steel universal beam in I shaped form theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam Bar IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

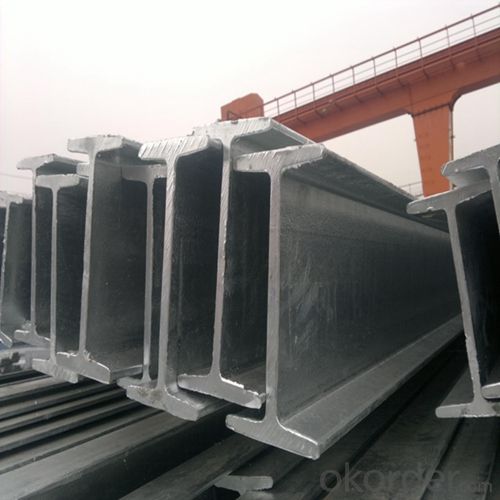

3. Steel I Beam Bar IPE Images:

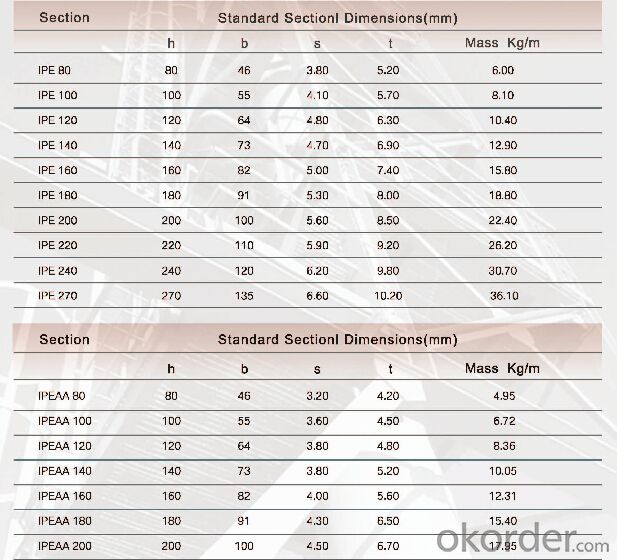

4. Steel I Beam Bar IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Are steel I-beams resistant to pests or insects?

- Steel I-beams have a high level of resistance against pests and insects, unlike wood, which is susceptible to termite infestations and other insect-related harm. Pests do not find steel beams appealing as a food source or habitat, making them an excellent choice for construction in areas with a high presence of pests. The durability and non-porous nature of steel also prevent pests from causing damage by burrowing into the beams. In addition, steel I-beams are not prone to rot or decay, further reducing the risk of attracting insects. Consequently, steel I-beams are widely regarded as highly resistant to pests and insects, offering long-lasting structural support without the concern of pest-related damage.

- Q: How do steel I-beams compare to other types of structural beams?

- Considered by many to be one of the most versatile and efficient structural beams, steel I-beams possess a multitude of advantages when compared to wooden or concrete beams. First and foremost, steel I-beams boast an exceptional strength-to-weight ratio. This characteristic allows them to bear heavy loads while remaining relatively lightweight. Consequently, they are an ideal choice for large-scale construction projects, such as bridges or skyscrapers, where minimizing the weight of the structure is crucial without compromising its strength. Secondly, steel I-beams exhibit remarkable durability and structural integrity. Steel, as a highly resilient material, can withstand extreme weather conditions including earthquakes, high winds, and heavy snow loads. Moreover, it boasts an extended lifespan and requires minimal maintenance, making it a cost-effective choice in the long run. Another advantage of steel I-beams lies in their flexibility and adaptability. They can be easily fabricated and customized to meet specific design requirements. Steel can be cut, shaped, and welded into various lengths and shapes, offering greater design flexibility. Consequently, it becomes possible to create intricate structures and achieve unique architectural designs. Additionally, steel I-beams provide superior fire resistance compared to their counterparts. Being non-combustible, steel does not contribute to the spread of fire. This feature makes it a safer option for buildings and structures, particularly in areas with stringent fire safety regulations. Lastly, steel I-beams are environmentally friendly. Steel is a recyclable material, allowing it to be reused or repurposed at the end of its life cycle. By recycling steel, natural resources can be conserved, and carbon emissions associated with the production of new steel can be reduced. To conclude, steel I-beams offer numerous advantages over other types of structural beams. These advantages include a high strength-to-weight ratio, durability, flexibility, fire resistance, and environmental sustainability. Given these qualities, it is no surprise that steel I-beams have become a popular choice in the construction industry for a wide range of applications.

- Q: How do you calculate the bending capacity of a steel I-beam?

- To calculate the bending capacity of a steel I-beam, you need to consider several factors such as the material properties of the steel, the shape and dimensions of the I-beam, and the applied load. Here is a step-by-step process to calculate the bending capacity: 1. Determine the material properties: Obtain the yield strength and modulus of elasticity of the steel being used. These values can typically be found in material specification documents or handbooks. 2. Identify the shape and dimensions of the I-beam: Measure the dimensions of the I-beam, including the flange width, flange thickness, web depth, and web thickness. The shape and dimensions of the I-beam will determine its section modulus (Z) and moment of inertia (I). 3. Calculate the section modulus (Z): The section modulus is a measure of a beam's resistance to bending. It can be calculated using the formula: Z = (b * h^2) / 6, where b is the flange width and h is the web depth. 4. Calculate the moment of inertia (I): The moment of inertia represents a beam's resistance to bending about its neutral axis. For an I-beam, the moment of inertia can be calculated using the formula: I = (b * h^3) / 12 + A * (d - h/2)^2, where A is the area of the flange and d is the total depth of the I-beam. 5. Determine the applied load: Identify the type and magnitude of the load that will be applied to the I-beam. This can be a uniformly distributed load (e.g., a floor load) or a concentrated load (e.g., a point load). 6. Calculate the bending stress: The bending stress, also known as the flexural stress, is calculated using the formula: σ = M / (Z * y), where M is the bending moment, Z is the section modulus, and y is the distance from the neutral axis to the extreme fiber. 7. Determine the maximum bending moment: Depending on the type of load applied, you will need to calculate the maximum bending moment using appropriate equations. For example, for a uniformly distributed load, the maximum bending moment can be calculated as M = (w * L^2) / 8, where w is the load per unit length and L is the span length. 8. Calculate the bending capacity: Finally, compare the calculated bending stress (σ) to the yield strength of the steel. If the bending stress is lower than the yield strength, the steel I-beam has sufficient bending capacity. However, if the bending stress exceeds the yield strength, the beam may experience plastic deformation or failure. It is important to note that this process provides an estimation of the bending capacity and should be used as a preliminary design tool. For accurate and precise calculations, it is recommended to consult with a structural engineer or refer to design codes and standards specific to your region.

- Q: How do engineers determine the required size of a steel I-beam for a specific application?

- Engineers determine the required size of a steel I-beam for a specific application by considering various factors such as the load it needs to support, the span it needs to cover, and the desired deflection limits. They analyze the structural requirements using mathematical formulas, computer simulations, and industry standards to ensure the I-beam can safely withstand the anticipated forces and maintain the desired level of structural integrity.

- Q: How are steel I-beams protected against rust?

- Steel I-beams are protected against rust through a process called corrosion protection. There are several methods used to prevent rusting and extend the lifespan of steel I-beams. One common method is the application of a coating or paint on the surface of the I-beams. The coating acts as a barrier between the steel and the surrounding environment, preventing moisture and oxygen from coming into contact with the metal. This helps to inhibit the formation of rust. Another method is the use of galvanization. In this process, the I-beams are dipped into a bath of molten zinc. The zinc coating forms a protective layer on the surface of the steel, acting as a sacrificial barrier. If any part of the steel is exposed due to damage, the zinc coating will corrode instead of the steel, providing ongoing protection against rust. Additionally, some manufacturers may use a combination of coatings and galvanization to provide enhanced protection against rust. These additional layers can further increase the resistance of the I-beams to corrosion. Regular maintenance and inspection also play a crucial role in protecting steel I-beams against rust. Any damage or signs of rust should be promptly addressed to prevent further corrosion. This may involve cleaning, re-coating, or repairing the affected areas. By implementing these protective measures, steel I-beams can have a significantly extended lifespan and maintain their structural integrity over time.

- Q: No. 10 I-beam for the main beam, 10 channel steel by the wall as auxiliary beam reinforcement, attic construction problems

- A loft is a room at the bottom of a house slope.

- Q: How do steel I-beams contribute to the overall safety of a structure?

- Steel I-beams contribute to the overall safety of a structure in several ways. Firstly, their design and construction make them incredibly strong and resistant to bending or twisting forces. This means that they can support heavy loads and distribute the weight evenly across the structure. By providing a strong and stable framework, steel I-beams minimize the risk of structural collapse, ensuring the safety of occupants. Additionally, steel I-beams have a high level of fire resistance. Steel has a high melting point, so it can withstand high temperatures for longer periods compared to other construction materials such as wood or concrete. This fire resistance reduces the risk of structural failure during a fire, giving occupants more time to evacuate the building safely. Moreover, steel I-beams are durable and long-lasting, with a high resistance to corrosion and degradation. This ensures that the structure remains intact and stable over time, reducing the risk of sudden failures or collapses. The strength and durability of steel I-beams also make them less susceptible to natural disasters such as earthquakes or strong winds, further enhancing the safety of the structure. In summary, steel I-beams contribute to the overall safety of a structure by providing a strong and stable framework, high fire resistance, and durability. Their ability to withstand heavy loads, distribute weight evenly, and resist bending or twisting forces ensures the structural integrity of the building, minimizing the risk of collapse. Combined with their fire resistance and durability, steel I-beams offer a reliable and secure foundation for a safe structure.

- Q: How do steel I-beams perform in seismic or earthquake-prone areas?

- Steel I-beams are commonly used in seismic or earthquake-prone areas due to their excellent performance during seismic events. The inherent strength and ductility of steel allow I-beams to absorb and distribute seismic forces, reducing the risk of structural failure. Additionally, the flexibility of steel I-beams helps them resist lateral movement, ensuring better stability and minimizing damage during earthquakes. Overall, steel I-beams are a reliable and preferred choice for construction in seismic regions.

- Q: Why are the rails made of I-beam?

- The type and strength of the rail are represented by kg/m. The heavier the rail, the greater the weight it can bear.

- Q: How are steel I-beams connected or joined together in construction?

- Various methods are commonly employed to connect or join steel I-beams in construction. Welding is a frequently utilized technique, wherein the ends of the I-beams are cleaned and beveled before being positioned and secured. A welder then applies heat to melt the edges, which fuse together, resulting in a durable and continuous connection between the I-beams. Another method used for connecting steel I-beams involves bolting. This method entails drilling holes through the flanges of the I-beams and inserting bolts, which are then tightened with nuts. Washers are often employed to evenly distribute the load and prevent damage to the flanges. Bolting allows for easier disassembly and reassembly when required. In certain cases, a combination of welding and bolting is employed to connect steel I-beams. This hybrid approach enhances the strength and stability of the connection, particularly in structures subject to high loads or vibrations. Furthermore, for long-span structures like bridges or large buildings, additional connections such as splice plates or fish plates may be utilized. These plates are generally bolted to the flanges or webs of the I-beams to provide extra support and ensure a secure connection. In conclusion, the connection or joining of steel I-beams in construction is crucial for ensuring the structural integrity and stability of the overall structure. The specific method chosen depends on design requirements, load-bearing capacity, and anticipated forces acting on the I-beams.

Send your message to us

Carbon Steel Universal Beam in I Shaped Form Chinese Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords