Hot Rolled Steel I-Beam For Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

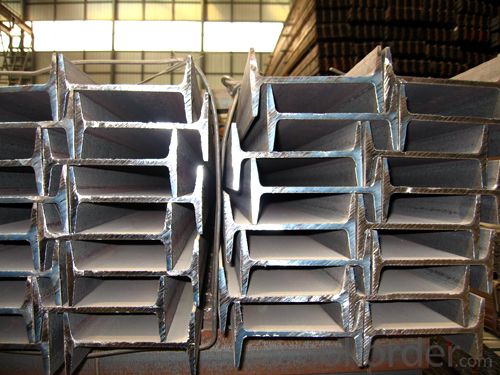

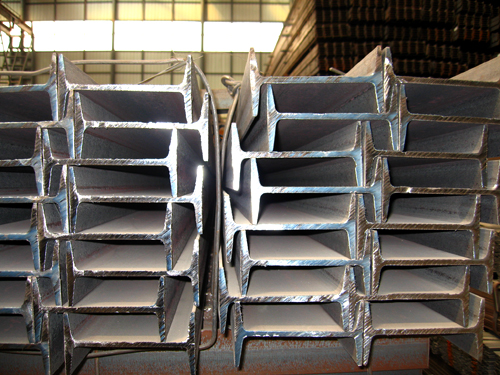

Images:

- Q: Are steel I-beams suitable for agricultural or industrial buildings?

- Indeed, agricultural and industrial buildings can rely upon steel I-beams as a suitable option. Renowned for their robustness and resilience, steel I-beams prove themselves as an excellent choice for bearing substantial burdens and enduring severe weather. Their versatility extends to various agricultural and industrial uses, encompassing the support of roofs, walls, and floors, as well as providing structural reinforcement for equipment and machinery. Moreover, steel I-beams exhibit resistance against pests, fire, and decay, rendering them a durable and economically sound selection for agricultural and industrial constructions.

- Q: How do steel I-beams compare to timber beams in terms of strength and durability?

- Steel I-beams are generally considered to be stronger and more durable than timber beams. Steel has a much higher strength-to-weight ratio than timber, meaning it can support heavier loads without bending or breaking. Additionally, steel is not susceptible to rot, insects, or fire like timber, which enhances its durability. Overall, steel I-beams are the preferred choice for structural applications where strength and long-term durability are crucial.

- Q: Can steel I-beams be used in water or wastewater treatment plant construction?

- Yes, steel I-beams can be used in water or wastewater treatment plant construction. Steel I-beams are commonly used in construction due to their strength, durability, and load-bearing capacity. In water or wastewater treatment plant construction, where structures need to withstand various environmental conditions and heavy loads, steel I-beams are often utilized for supporting platforms, walkways, tanks, and other critical infrastructure components.

- Q: Can steel I-beams be used as columns or posts in construction?

- Yes, steel I-beams can be used as columns or posts in construction. They are commonly used in structural applications where strength and durability are required. I-beams provide excellent load-bearing capacity and are often preferred for their ability to support heavy loads and resist bending or buckling.

- Q: Can steel I-beams be used in stadium construction?

- Yes, steel I-beams can be used in stadium construction. In fact, they are commonly used due to their strength, durability, and ability to support heavy loads over long spans.

- Q: What are the different accessories or attachments used with steel I-beams?

- There are several accessories or attachments that are commonly used with steel I-beams to enhance their functionality and structural integrity. Some of these accessories include: 1. Beam clamps: These are used to attach the steel I-beams to other structural elements or support systems. Beam clamps come in various designs and sizes to accommodate different beam sizes and load requirements. 2. Beam connectors: These are connectors that join two or more steel I-beams together, creating a continuous beam. They are typically used in long-span applications or when additional strength is required. 3. Beam hangers: Beam hangers are used to suspend the steel I-beams from overhead structures or support systems. They provide a secure and reliable means of supporting the beams, especially in applications where there is limited space for support columns. 4. Lateral braces: Lateral braces are used to provide additional stability and prevent lateral movement of the steel I-beams. They are typically installed at regular intervals along the length of the beam and can be either welded or bolted to the beam. 5. End plates: End plates are used to connect the ends of steel I-beams to other structural elements or support systems. They are typically bolted or welded to the beam ends and provide a secure connection that can withstand high loads and forces. 6. Cleats: Cleats are small steel plates that are welded or bolted to the sides of the steel I-beams. They are used to provide additional support and prevent twisting or rotation of the beams under load. 7. Brackets: Brackets are used to support other components or fixtures that are attached to the steel I-beams. They can be either welded or bolted to the beams and are commonly used to support equipment, lighting fixtures, or other building systems. These accessories and attachments play a crucial role in ensuring the proper installation, support, and functionality of steel I-beams in various construction and structural applications.

- Q: Does the welding of I-beam affect its structure after welding?

- It can be splicedBut both the web and the upper and lower panels should be welded and strengthened

- Q: Can Steel I-Beams be painted or coated for corrosion protection?

- Yes, steel I-beams can be painted or coated for corrosion protection.

- Q: Can steel I-beams be used for theater stage supports?

- Yes, steel I-beams can be used for theater stage supports. They are commonly used in the construction of theater stages due to their strength, durability, and ability to support heavy loads.

- Q: How do steel I-beams perform in terms of impact insulation?

- Typically, impact insulation purposes do not involve the use of steel I-beams. These beams are primarily employed for structural support in construction projects. Nevertheless, their rigid and dense nature may offer some degree of impact resistance. When faced with an impact, steel I-beams are engineered to endure the force and disperse it along their length, thereby minimizing the impact's influence on the surrounding structure. Nonetheless, their capacity to absorb or mitigate impact energy is limited when compared to materials specifically designed for impact insulation, such as foam or rubber. If impact insulation is an essential requirement, it is advisable to explore alternative materials or methods that are explicitly intended for this purpose.

Send your message to us

Hot Rolled Steel I-Beam For Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords