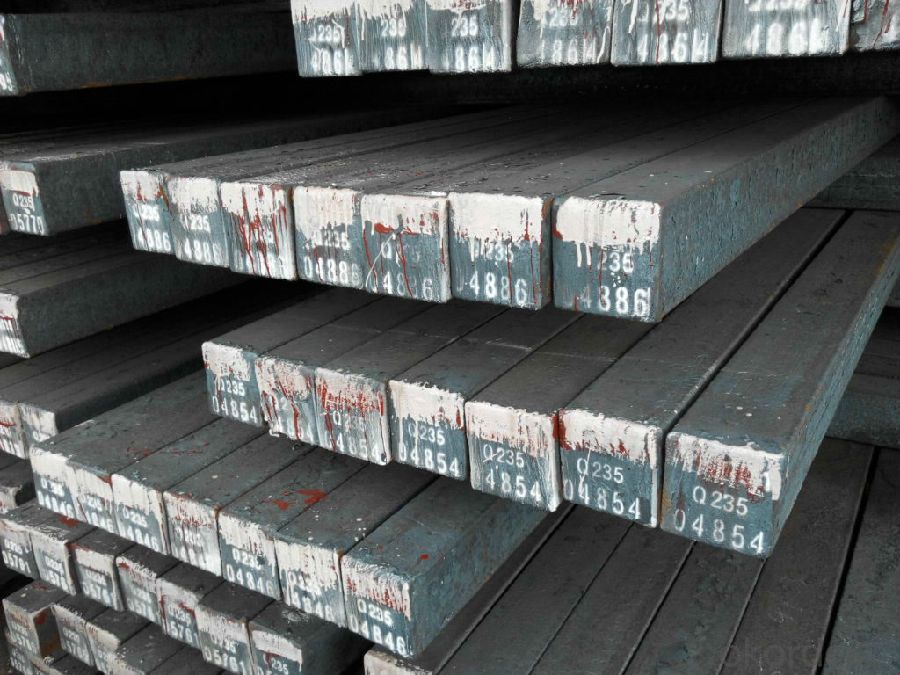

Steel Billets CarbonQ275/3SP in China Square Billets for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

Festures of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products. Billets are used fro rolling of CRS TMT Re-Bars..

Product Size of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Technology process of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Products Show

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How are steel billets shaped into other forms?

- A process known as hot rolling is used to transform steel billets into different forms. This process involves feeding the steel billet through heated rollers, which compress and mold it into the desired shape. To begin, the steel billet is heated to a high temperature in a furnace. This heat treatment makes the steel more malleable and easier to shape. Once the billet has reached the desired temperature, it is then sent into a rolling mill. Within the rolling mill, the billet undergoes a series of passes through rollers that apply pressure and force to shape the steel. These rollers come in various shapes and sizes depending on the desired outcome. As the billet passes through the rollers, it gradually takes on the desired form, such as sheets, bars, or beams. The rolling process not only shapes the steel but also improves its mechanical properties. It refines the grain structure, enhances strength and toughness, and eliminates any internal defects. This makes the steel more suitable for a range of applications, including construction, automotive, and machinery. Following the hot rolling process, the steel often undergoes additional processing through cold rolling. This involves passing the steel through cold rollers to further refine its surface finish and dimensions. Additionally, secondary operations like cutting, bending, and welding may be carried out to further shape the steel into the desired end product. In conclusion, hot rolling plays a vital role in transforming steel billets into various forms. It enables the production of a wide range of steel products, each with its own unique shape, size, and mechanical properties. This helps meet the diverse needs of industries worldwide.

- Q: How do steel billets contribute to the overall thermal insulation of a structure?

- Steel billets do not contribute to the overall thermal insulation of a structure. In fact, steel is a good conductor of heat and can transfer heat quickly, making it a poor choice for thermal insulation.

- Q: How is the strength of steel billets measured?

- The strength of steel billets is typically measured using a tensile test, where a sample is subjected to pulling forces until it fractures. The maximum force applied during the test is recorded and used to determine the strength of the steel.

- Q: How are steel billets used in the manufacturing of springs?

- Steel billets are used in the manufacturing of springs by being heated and then forged or rolled into the desired shape and size. These billets serve as the raw material for producing high-quality springs, providing the necessary strength and durability required for various applications.

- Q: The role of carbon content in steels

- 2., the formation of carbide structure, can improve the hardness and wear resistance of steel, such as cementite, or Fe3C, that is, carbide organizationTherefore, the higher the carbon content in carbon steel, the higher the strength and hardness of the steel, but the plasticity and toughness will also be reduced. On the contrary, the lower the carbon content, the higher the plasticity and toughness of the steel, and its strength and hardness will also decrease

- Q: What is the role of steel billets in the construction of underground tunnels?

- Steel billets play a crucial role in the construction of underground tunnels as they are used to create the reinforced steel framework. These billets are shaped into various structural components, such as bars and beams, which provide strength and stability to the tunnel structure. The reinforced steel framework helps to distribute the load evenly, withstand the pressure from the surrounding soil or rock, and prevent any potential collapse or deformation of the tunnel. Therefore, steel billets contribute significantly to the overall durability and safety of underground tunnels.

- Q: What are the different surface defects found in alloy steel billets?

- Some common surface defects found in alloy steel billets include cracks, laps, seams, scabs, and surface scale. These defects can occur during the manufacturing process or as a result of handling and transportation.

- Q: What are the different types of steel billet forging machines?

- There are several different types of steel billet forging machines available in the market today. These machines are designed to efficiently shape and form steel billets into desired shapes and sizes. Here are some of the common types of steel billet forging machines: 1. Hydraulic Forging Press: This type of machine uses hydraulic power to exert force on the steel billet, allowing it to be forged into the desired shape. Hydraulic forging presses are known for their high force capabilities and versatility in handling different sizes of billets. 2. Mechanical Forging Press: Mechanical forging presses use mechanical power, such as flywheels or eccentric mechanisms, to exert force on the billet. These machines are known for their reliability and precision, making them suitable for high-volume production. 3. Screw Press: Screw presses utilize a rotating screw mechanism to apply force on the steel billet. They are characterized by their high-speed operation and efficient energy usage. Screw presses are commonly used for forging small to medium-sized billets. 4. Hammer Forging Machine: Hammer forging machines use a hammering action to shape the steel billet. There are various types of hammer forging machines, including steam hammers, air hammers, and hydraulic hammers. These machines are known for their high impact force, making them suitable for heavy-duty forging. 5. Upsetter: Upsetters, also known as upsetting machines, are specifically designed for forging the ends of steel billets. They use a vertical or horizontal ram to apply pressure on the billet, causing it to increase in diameter and length. Upsetters are commonly used for producing forged components with thickened ends. 6. Radial Forging Machine: Radial forging machines employ a rotating roller to apply radial force on the steel billet. This force causes the billet to increase in diameter while maintaining its original length. Radial forging machines are often used for producing seamless rings and other cylindrical components. It's important to note that the choice of the most suitable steel billet forging machine depends on factors such as the size and shape of the billet, desired production volume, and specific requirements of the final product. Each type of machine has its own advantages and limitations, so it is crucial to consider these factors when selecting the appropriate forging machine for a given application.

- Q: What is the role of steel billets in the manufacturing of material handling equipment?

- Steel billets play a crucial role in the manufacturing of material handling equipment. These billets are essentially semi-finished steel products that are used as the raw material for various manufacturing processes. In the context of material handling equipment, steel billets are typically used in the fabrication of heavy-duty components such as frames, beams, and brackets. These components need to possess high strength, durability, and resistance to wear and tear in order to withstand the demanding conditions that material handling equipment often operates in. The use of steel billets allows manufacturers to create these components with the necessary mechanical properties. The billets are first heated and then shaped through processes like rolling, forging, or extrusion to produce the desired shape and dimensions. This shaping process ensures that the components have the required strength and structural integrity to handle the weight and stress associated with material handling tasks. Furthermore, steel billets offer excellent weldability, which is crucial in the fabrication of material handling equipment. The ability to weld the components together ensures that the equipment can be assembled securely and efficiently. This is especially important for equipment such as cranes, forklifts, and conveyors, where the safe and efficient movement of heavy loads is paramount. Moreover, steel billets provide a cost-effective solution for manufacturing material handling equipment. Steel is widely available, relatively affordable, and can be recycled, making it a sustainable choice. The versatility of steel billets also allows manufacturers to create components of various shapes and sizes, enabling customization to meet specific requirements. Overall, the role of steel billets in the manufacturing of material handling equipment is crucial. They provide the raw material necessary to create strong, durable, and reliable components that can withstand the demanding conditions of material handling tasks. With their excellent mechanical properties and weldability, steel billets contribute to the safe and efficient operation of material handling equipment.

Send your message to us

Steel Billets CarbonQ275/3SP in China Square Billets for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords