Self Adhesive Brushed Aluminum Sheets with Low Price - China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Brushed Sheet Metal Aluminum with Low Price China Supply

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Brushed Sheet Metal Aluminum with Low Price China Supply

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

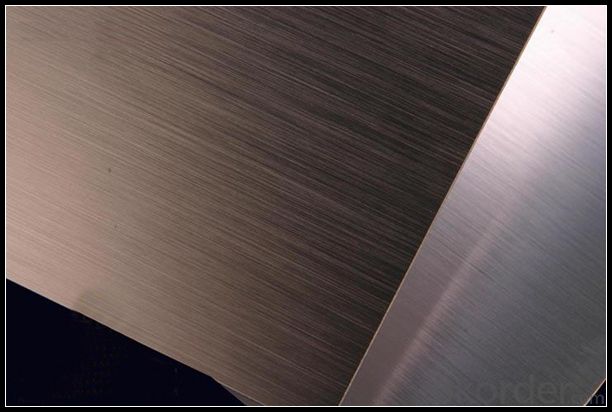

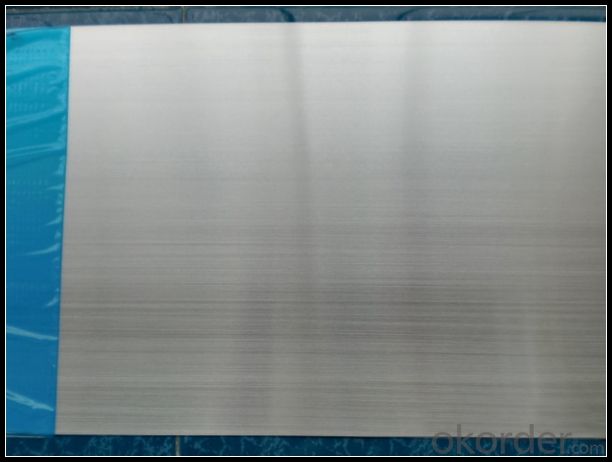

3. Brushed Sheet Metal Aluminum with Low Price China Supply Images

4.Specification of Brushed Sheet Metal Aluminum with Low Price China Supply

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: are there any carbonated mineral water that are produced in aluminium cans.

- Aluminium cans have an oxide covering on them so the reaction between them and the carbonated water is so little if any that it can't be noticed. Aluminium is also not so high on the reactivity series

- Q: Are aluminum sheets suitable for transportation applications?

- Indeed, aluminum sheets prove to be appropriate for transportation purposes. With its lightweight and robust nature, aluminum emerges as an ideal material for diverse transportation needs. It finds widespread use in the aerospace sector, where it is employed in constructing aircraft structures. Similarly, in the automotive industry, aluminum is extensively utilized for fabricating vehicle bodies, frames, and components. By incorporating aluminum sheets into transportation applications, the overall weight of vehicles can be reduced, thereby enhancing fuel efficiency and increasing payload capacity. Moreover, aluminum's resistance to corrosion ensures its durability and longevity, even in harsh environments. All in all, the attributes of aluminum sheets render them a suitable and optimal choice for transportation applications.

- Q: I have a lot of old aluminum cake pans, coffee pots, pots and pans and various old nuts and bolts made of aluminum. Would it be worth it to scrap them? They really aren't usable for cooking anymore. They are clean.

- Aluminum is currently scrap priced at eighty cents per pound. If you have enough to justify the gasoline to go to a scrap yard, yes it is worth it. Your scrap will end up in Japan rather than in a landfill.

- Q: How do you prevent warping of aluminum sheets during machining?

- To prevent warping of aluminum sheets during machining, there are several steps that can be taken: 1. Proper material selection: Choosing the right grade of aluminum is crucial to minimize warping. Aluminum alloys with lower levels of thermal expansion, such as 6061 or 7075, are less prone to warping during machining. 2. Stabilize the material: Before machining, it is recommended to anneal or stress-relieve the aluminum sheets. This process helps to reduce internal stresses within the material and minimize the chances of warping. 3. Use appropriate cutting tools: The selection of cutting tools is critical to prevent warping. Tools with sharp edges and proper geometry should be used to minimize heat generation and ensure efficient chip removal. Carbide or diamond-coated tools are often preferred for machining aluminum as they have high heat resistance. 4. Minimize heat generation: Excessive heat can cause the aluminum sheet to warp. To prevent this, coolant or lubricants should be used during machining to reduce friction and dissipate heat. Continuous cooling can help maintain a stable temperature and prevent warping. 5. Control cutting parameters: Proper control of cutting parameters such as cutting speed, feed rate, and depth of cut is essential to prevent warping. High cutting speeds or excessive material removal rates can generate excessive heat, leading to warping. Optimal parameters should be determined through experimentation and experience. 6. Use appropriate fixturing: During machining, proper fixturing is crucial to minimize the chances of warping. Securely clamping the aluminum sheets using appropriate fixtures or jigs helps to maintain stability and prevent movement during machining. 7. Consider machining techniques: Certain machining techniques, such as climb milling or ramping, can help reduce the chances of warping. These techniques minimize vibrations and ensure a smoother cutting process, reducing the risk of warping. 8. Post-machining treatment: After machining, it is recommended to stress-relieve the aluminum sheets again. This step can help further reduce any residual stress that may have developed during the machining process. By following these steps, it is possible to significantly reduce the chances of warping during the machining of aluminum sheets, ensuring high-quality finished products.

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets involves creating a pattern of holes or perforations in the metal surface. These perforations can serve various purposes depending on the specific application. For decorative purposes, perforated aluminum sheets are commonly used in architecture and interior design. The patterns of holes can add visual interest and create unique designs, allowing for the play of light and shadow. It can be used for decorative screens, partitions, facades, and ceiling panels, among other applications. Perforated aluminum sheets offer versatility in design, as different hole sizes, shapes, and arrangements can be used to achieve the desired aesthetic effect. In terms of functional purposes, perforated aluminum sheets provide several advantages. Firstly, they can improve airflow and ventilation in applications such as HVAC systems, air-conditioning units, and speaker grilles. The perforations allow air to pass through while still maintaining the structural integrity of the sheet. Secondly, perforated aluminum sheets can be used for sound absorption and noise reduction. The holes in the sheet disrupt sound waves, reducing noise levels in areas such as auditoriums, concert halls, and industrial facilities. Additionally, perforated aluminum sheets have practical applications in filtration and separation processes. They can be used as screens or sieves to separate particles of different sizes, allowing for the filtration of liquids or gases. These sheets are also used in the manufacturing of various industrial equipment, such as vibrating screens, grain dryers, and centrifuges. In summary, aluminum sheets can indeed be perforated for both decorative and functional purposes. Whether it is to enhance the visual appeal of a space, improve airflow, reduce noise levels, or aid in filtration processes, perforated aluminum sheets offer a versatile solution for a wide range of applications.

- Q: Can aluminum sheets be used for solar panel applications?

- Yes, aluminum sheets can be used for solar panel applications. Aluminum is a lightweight and durable material that is commonly used for the frames and backings of solar panels. It offers good corrosion resistance and can efficiently dissipate heat, making it suitable for solar panel installations.

- Q: Can aluminum sheets be used for signage?

- Yes, aluminum sheets can be used for signage. Aluminum is a versatile material that is durable, lightweight, and weather-resistant, making it suitable for outdoor and indoor signage applications. It can be easily customized, cut, and shaped to create various types of signage, including signs for businesses, roadways, and informational displays.

- Q: Are aluminum sheets suitable for lightweight structures?

- Yes, aluminum sheets are suitable for lightweight structures. Aluminum is known for its low density and high strength-to-weight ratio, making it an ideal material for lightweight applications. Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction, where weight reduction is crucial. They offer excellent corrosion resistance, durability, and formability, allowing for easy fabrication and installation. Additionally, aluminum sheets can be easily joined using various welding and adhesive techniques, further enhancing their suitability for lightweight structures.

- Q: What is the fatigue life of aluminum sheets?

- The endurance capacity of aluminum sheets pertains to the number of cycles the material can endure before failure arises under cyclic loading circumstances. Various factors, including the composition, thickness, surface finish, loading conditions, and environmental elements, can cause the endurance capacity of aluminum sheets to differ. Aluminum is renowned for its relatively high fatigue strength in comparison to other materials, rendering it a favored option in industries like aerospace, automotive, and construction. The endurance capacity of aluminum sheets is typically influenced by the presence of microstructural flaws, such as inclusions, voids, and grain boundaries. Fatigue tests are conducted, utilizing standardized procedures like ASTM E466 or ASTM E606, to ascertain the endurance capacity of aluminum sheets. These tests entail subjecting the material to cyclic loading conditions, usually at a consistent stress or strain amplitude, while monitoring the number of cycles required for failure to arise. The outcomes are then employed to generate an S-N curve, which represents the connection between the applied stress or strain amplitude and the number of cycles until failure. The S-N curve furnishes valuable insights into the endurance capacity of aluminum sheets, indicating the stress or strain levels at which the material can withstand a specific number of cycles before failure. It is crucial to note that the endurance capacity of aluminum sheets can be enhanced through various approaches, such as alloying, heat treatment, surface treatment, and appropriate design considerations. To conclude, the endurance capacity of aluminum sheets plays a pivotal role in the design of components or structures exposed to cyclic loading conditions. By comprehending the specific properties and characteristics of the aluminum alloy, coupled with proper testing and analysis, it is possible to ascertain the endurance capacity and guarantee the safe and dependable performance of aluminum sheets in diverse applications.

- Q: 10mm how much is the aluminum sheet?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liaoning Wang Zhong Nanshan aluminum do this thickness.

Send your message to us

Self Adhesive Brushed Aluminum Sheets with Low Price - China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords