Brushed Silver Aluminum Sheets for Consumer Electronics Casing - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Consumer Electronics Casings Aluminium Description:

Zinc is the main alloying elements in 7075, adds to the 3%-7.5% of zinc-containing alloys of magnesium, can form the strengthening effect of MgZn2, make the alloy heat treatment effect than on the aluminum-zinc alloy. Improve the content of zinc and magnesium alloys, the tensile strength will be further improved, but its resistance to stress corrosion and spalling corrosion will decline. Subjected to heat treatment and can reach very high strength characteristics. 7075 material is generally a small amount of copper, chrome, alloy, the 7075T651 aluminum alloy is the top grade, known as the most excellent products in aluminum alloy, high strength, far better than any mild steel.

2.Main Features of Consumer Electronics Casings Aluminium:

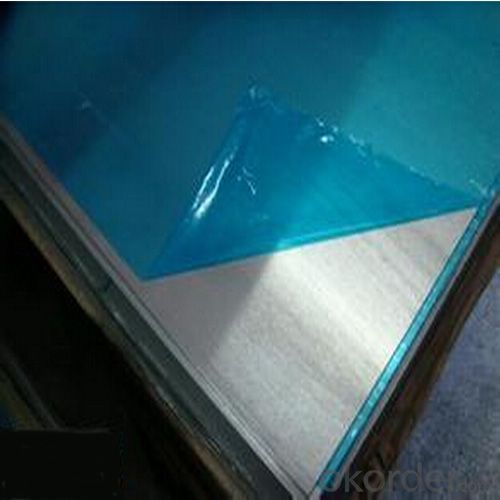

PVC Protect Film

Waterproof paper

High Quality

Competitive Price

3. Consumer Electronics Casings Aluminium Images:

4. Consumer Electronics Casings Aluminium Specification:

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 0.2-200mm aluminium 5050 H38 |

Width | 1250mm 1000mm or as your requirements |

Length | 3000mm 5800mm or as your requirements |

MOQ | 5 Ton |

Package | Standard export package, by wooden box or as require |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum sheets be used for furniture manufacturing?

- Yes, aluminum sheets can be used for furniture manufacturing. Aluminum is a versatile material with several advantageous properties that make it suitable for furniture production. It is lightweight, durable, corrosion-resistant, and can be easily molded into various shapes and sizes. Additionally, aluminum has a sleek and modern aesthetic, making it a popular choice for contemporary furniture designs. Aluminum sheets can be used to create frames, legs, and other structural components for different types of furniture, including chairs, tables, shelves, and cabinets. The versatility and durability of aluminum make it a viable option for furniture manufacturing, especially for outdoor or industrial furniture that requires resistance to harsh weather conditions or heavy use.

- Q: Can aluminum sheets be used for bus bodies?

- Yes, aluminum sheets can be used for bus bodies. Aluminum is a lightweight yet durable material that offers excellent corrosion resistance, making it a popular choice for constructing bus bodies. Its high strength-to-weight ratio allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum can be easily molded and shaped, enabling manufacturers to design buses with unique and modern aesthetics.

- Q: How do aluminum sheets perform in terms of dimensional stability?

- Aluminum sheets generally exhibit good dimensional stability due to their low coefficient of thermal expansion, meaning they are less likely to warp or deform when exposed to temperature changes compared to other materials.

- Q: Can aluminum sheets be used for decorative panels?

- Yes, aluminum sheets can be used for decorative panels. Aluminum is a versatile material that can be easily shaped, textured, and colored, making it suitable for various decorative applications. Its lightweight nature, durability, and resistance to corrosion also make it a popular choice for decorative panels in both indoor and outdoor settings.

- Q: Are aluminum sheets suitable for signage and advertising?

- Aluminum sheets prove to be an excellent choice for signage and advertising purposes due to their numerous advantages. Not only is aluminum a durable and lightweight material, but it also possesses the ability to endure outdoor weather conditions and transportation, making it highly suitable for creating signs. Furthermore, its resistance to rust and corrosion guarantees that the signs will maintain their appearance and functionality for an extended period of time. In terms of versatility, aluminum sheets can be effortlessly cut and shaped into various sizes and designs, catering to different advertising needs. Moreover, the smooth surface of aluminum allows for high-quality printing and graphics, resulting in exceptional visibility and readability for signage. In conclusion, aluminum sheets are a practical and effective option for signage and advertising, offering durability, versatility, and aesthetic appeal.

- Q: Describe the steps involved in the production of aluminum sheets.

- <p>The process of manufacturing aluminum sheets involves several key steps. Initially, raw materials, primarily bauxite, are mined and then processed to extract alumina (aluminum oxide). This alumina is then mixed with cryolite and fed into a reduction cell where it is subjected to a strong electric current, causing the aluminum to be reduced and extracted. The molten aluminum is then poured into molds to cool and solidify into ingots. These ingots are subsequently rolled into sheets in a hot or cold rolling process, where they are gradually reduced in thickness and width. The sheets are then annealed to improve their ductility and strength. Finally, they undergo various finishing processes such as cleaning, coating, or cutting to meet specific requirements before being packaged and shipped to customers.</p>

- Q: Are the aluminum sheets suitable for manufacturing automotive body panels?

- Indeed, automotive body panels can be manufactured using aluminum sheets. Aluminum, being a material that is both lightweight and robust, presents numerous advantages in the realm of automotive applications. Its high ratio of strength to weight enables enhanced fuel efficiency and superior overall vehicle performance. Furthermore, aluminum boasts exceptional corrosion resistance, rendering it suitable for enduring adverse environmental conditions. Moreover, its malleability and ease of manipulation facilitate the creation of intricate designs and shapes essential for automotive body panels. These attributes have established aluminum sheets as a highly favored option within the automotive industry for the production of body panels.

- Q: I have to find the type of bond that Aluminum (foil) would have. I know that it has some kind of bond to it because that's the kind of question that I got wrong on my last quiz.

- Yes it will be a covalent bond. The simplest compound will be CH4 where each of the electron from the four H will be shared with one each from C to provide 4 covalent bonds.

- Q: Can aluminum sheets be used for boat building?

- Yes, aluminum sheets can be used for boat building. Aluminum is a popular material choice for boat construction due to its lightweight nature, durability, and resistance to corrosion. Aluminum sheets are commonly used in the construction of small recreational boats, larger yachts, and even commercial vessels. They offer several advantages such as being easy to work with, providing excellent strength-to-weight ratio, and requiring minimal maintenance. Additionally, aluminum boats are known for their superior buoyancy, stability, and fuel efficiency. Overall, aluminum sheets are a suitable and reliable option for boat building.

- Q: Can 101 aluminum sheets be used in food storage containers?

- Using 101 aluminum sheets in food storage containers is not recommended. These aluminum sheets, often referred to as 101 aluminum, are not suitable for storing food as they are not made from food-grade materials. Typically, they are employed in industrial settings like roofing, construction, and electrical wiring. To guarantee the safety and quality of stored food, it is essential to use containers crafted from food-grade materials such as stainless steel, glass, or food-grade plastic.

Send your message to us

Brushed Silver Aluminum Sheets for Consumer Electronics Casing - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords