Brushed Anodized Aluminum Sheets for Sale China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Brushed Anodized Aluminum Sheets for Sale China Supply

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Brushed Anodized Aluminum Sheets for Sale China Supply

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

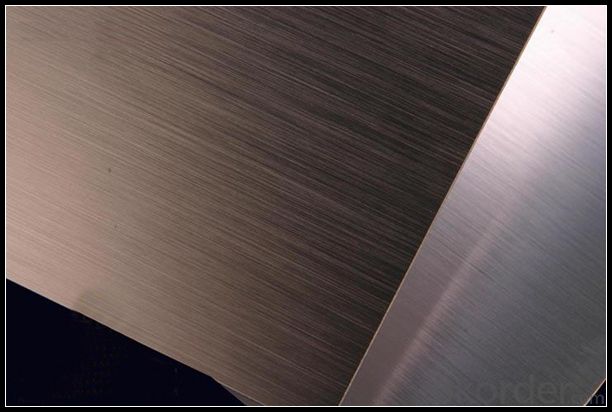

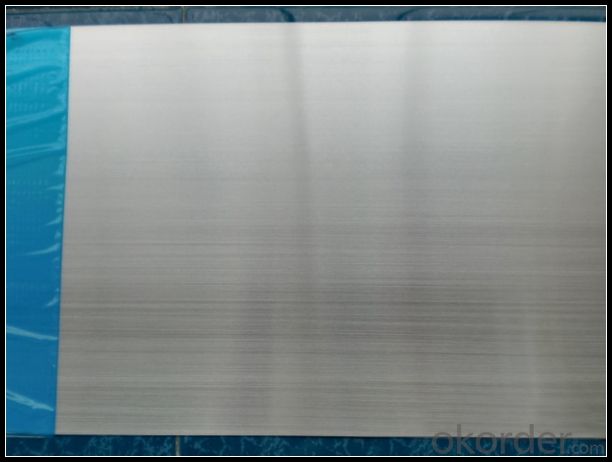

3. Brushed Anodized Aluminum Sheets for Sale China Supply Images

4.Specification of Brushed Anodized Aluminum Sheets for Sale China Supply

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Explain the distinctions between aluminum sheets and aluminum foil in terms of thickness, uses, and properties.

- <p>Aluminum sheets and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum sheets are thicker and more rigid, typically used for construction, manufacturing, and as a packaging material. They offer better strength and durability. Aluminum foil, on the other hand, is very thin and flexible, commonly used for food packaging, cooking, and insulation. It's lightweight and has excellent heat and light reflection properties. Aluminum sheets are often anodized or coated for additional properties, while foil is valued for its purity and malleability.</p>

- Q: Can aluminum sheets be used for electrical conductors?

- Aluminum sheets have the capability to function as electrical conductors. Despite being less efficient than copper, aluminum demonstrates good electrical conductivity. Nevertheless, owing to its lightweight properties, affordability, and resistance to corrosion, aluminum is frequently employed in various electrical applications. It finds extensive use in power distribution lines, wiring systems, and electrical equipment.

- Q: What specific criteria or conditions must be met when utilizing high-quality aluminum sheets in construction?

- <p>High-quality aluminum sheets used in construction projects require adherence to specific standards. They must possess high strength, corrosion resistance, and durability to withstand environmental conditions. Compliance with industry standards such as ASTM or ISO is crucial. Additionally, the sheets should be compatible with other construction materials and meet safety regulations. Proper installation techniques and qualified personnel are also essential to ensure the integrity and longevity of the construction project.</p>

- Q: What characteristics distinguish aluminum sheets from other types of sheets?

- <p>Aluminum sheets are lightweight, corrosion-resistant, and have excellent thermal and electrical conductivity. They are commonly used in construction, automotive, and packaging industries. In contrast, other types of sheets, such as steel sheets, are heavier and stronger but less resistant to corrosion. Plastic sheets are lightweight and flexible but have lower strength and thermal conductivity. Copper sheets offer high thermal and electrical conductivity but are more expensive and less resistant to corrosion than aluminum. Each type of sheet has unique properties that make it suitable for specific applications.</p>

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: What is the tensile strength of 101 aluminum sheets?

- The tensile strength range for 101 aluminum sheets can differ based on a variety of factors, including the manufacturing process, heat treatment, and specific alloy composition. Typically, 101 aluminum sheets exhibit a tensile strength of about 27,000 to 42,000 pounds per square inch (psi). It is crucial to acknowledge that this range is only an estimation, and real tensile strength values may have slight variations. To accurately determine the precise tensile strength of 101 aluminum sheets, it is advisable to consult the manufacturer's data sheet or conduct additional testing.

- Q: This question asks for a list of the various types of profiles that can be made from aluminum sheets.

- <p>Aluminum sheet profiles come in a variety of types, suitable for different applications. Some common types include: 1. Flat Sheets: These are simple, flat aluminum sheets with no bends or curves. 2. Corrugated Sheets: These have a wavy or ridged pattern, providing strength while allowing flexibility. 3. Perforated Sheets: These have holes punched in a regular pattern, useful for ventilation or decorative purposes. 4. Embossed Sheets: These have a raised pattern on the surface, often used for aesthetic or functional reasons. 5. Extruded Profiles: These are complex shapes created by pushing aluminum through a die, suitable for structural applications. 6. Expanded Metal Sheets: These have a diamond-shaped pattern, providing strength and rigidity. 7. Checkered Plates: These have a raised, non-slip pattern, often used for flooring. Each type has its own specific uses and properties, and the choice depends on the requirements of the project.</p>

- Q: Are the aluminum sheets suitable for manufacturing solar reflectors?

- Yes, aluminum sheets are suitable for manufacturing solar reflectors. Aluminum is a highly reflective material that can efficiently reflect sunlight, making it an ideal choice for solar reflectors. It has a high reflectivity and low emissivity, allowing it to reflect a significant amount of solar radiation while minimizing heat absorption. Additionally, aluminum is lightweight, durable, and corrosion-resistant, making it suitable for outdoor applications. Its flexibility also allows for easy shaping and forming into various reflector designs. Overall, aluminum sheets provide excellent performance and reliability for manufacturing solar reflectors in solar energy systems.

- Q: I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- elmers glue! Lol. I believe you can have it welded. That will last for a while.or until you can get another one.

- Q: Can the aluminum sheets be used for manufacturing chemical reaction vessels?

- Yes, aluminum sheets can be used for manufacturing chemical reaction vessels.

Send your message to us

Brushed Anodized Aluminum Sheets for Sale China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords