Aluminum Sheet Price Factory and Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Sheet Price Factory and Best Quality in China

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

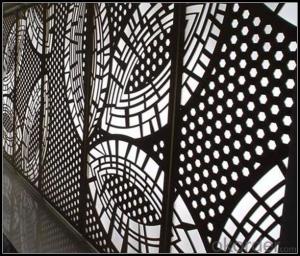

2. Application of Aluminum Sheet Price Factory and Best Quality in China

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

Feature of Aluminum Sheet Price Factory and Best Quality in China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

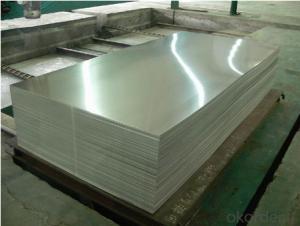

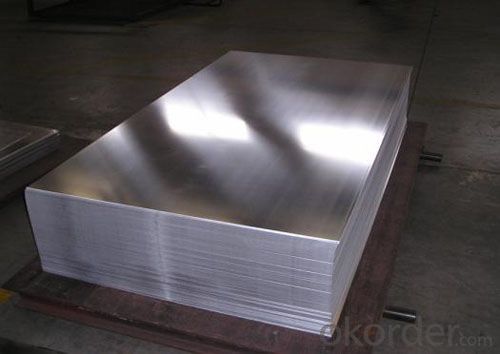

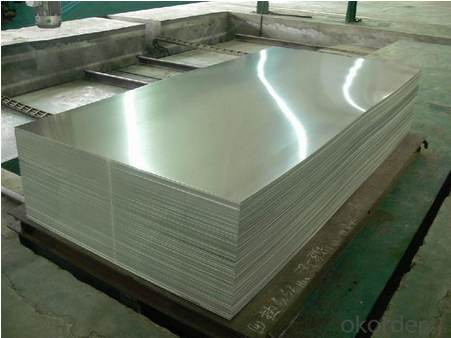

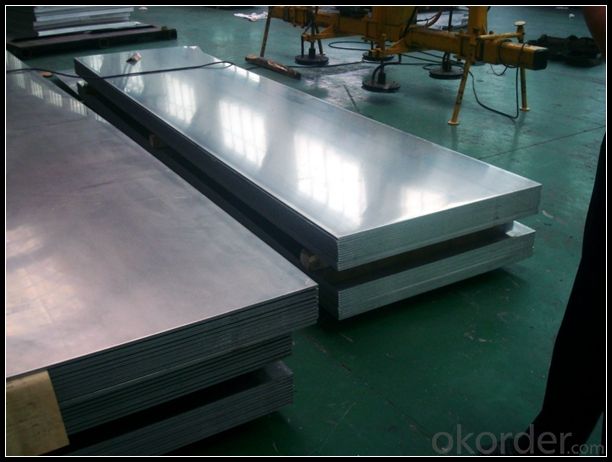

5. Image of Aluminum Sheet Price Factory and Best Quality in China

6. Package and shipping of Aluminum Sheet Price Factory and Best Quality in China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

Steel or Aluminium Fabrication - Which Is the Better Option for You?

You need custom fabricated application for your business or home. There are many important decisions which you have to make in order to get the best solution from the professional contractor that you have chosen. One of them is which metal will be most suitable for your needs. The main options which you have available are two - steel and aluminium fabrication. Find out how the two compare to make the right decision.

The Two Metals Compared

How suitable is each of the two materials for sheet metal fabrication? Aluminium is generally more malleable. This means that it can be fabricated into more intricate shapes. Similarly, smaller components can be made from it as well. Still, most of the applications required by business and households such as platforms and ductwork are fairly large and have basic shapes.

Steel is certainly the stronger of the two metals. It is less likely to get bent, deformed or dented when it is exposed to great weight, force or heat. At the same time, the strength of the other metal can be increased as well. This is done through its mixing with copper and magnesium for producing alloys.

Aluminium is resistant to corrosion and this is its major advantage. It is suitable for all kinds of outdoor applications and for ones which are designed to be in contact with liquids or moisture. Steel can be made more resistance to corrosion as well. This is done through the application of protective metal coatings via specific processes such as galvanization.

Individual Requirements

Both metals have their own benefits and advantages. That is why the best way to choose between aluminium and steel fabrication is to consider the application which you require, where it will be set up and how it will be used. This will help you to make the final decision.

The first thing which you need to check is whether there are any specific standards and legal requirements which the application has to meet. For example, facilities which are used for the production and serving of foods and beverages typically need to be made from stainless steel as this material is hygienic and does not have any impact on their taste.

You also need to take into account the kind of weight which the application will bear. This is extremely important in the case of platforms, walkways, mounts, ladders and truck trailers. You have to check whether the application will be exposed to moisture especially in the case of ductwork and piping.

- Q: Can aluminum sheets be used for furniture manufacturing?

- Yes, aluminum sheets can be used for furniture manufacturing. Aluminum is a versatile material with several advantageous properties that make it suitable for furniture production. It is lightweight, durable, corrosion-resistant, and can be easily molded into various shapes and sizes. Additionally, aluminum has a sleek and modern aesthetic, making it a popular choice for contemporary furniture designs. Aluminum sheets can be used to create frames, legs, and other structural components for different types of furniture, including chairs, tables, shelves, and cabinets. The versatility and durability of aluminum make it a viable option for furniture manufacturing, especially for outdoor or industrial furniture that requires resistance to harsh weather conditions or heavy use.

- Q: This question asks for precautions or methods to protect aluminum sheets from damage during the installation process.

- <p>To ensure that the installation process does not damage aluminum sheets, follow these steps: Use protective gloves to avoid scratches from hand oils or dirt. Employ non-marring tools to prevent any indentations or marks. Handle the sheets carefully to avoid bending or denting. Keep the surface clean and dry to prevent any chemical reactions or stains. Use appropriate support structures to distribute weight evenly and prevent warping. Always follow the manufacturer's guidelines for installation to avoid any improper handling that could lead to damage. Regularly inspect the sheets for any signs of damage during the installation process and address any issues promptly.</p>

- Q: 1mm the aluminum plate is pulled to the height of 45mm. Can I pull it out at 1? How much space should I put in?

- The clearance value of the stretched aluminum plate is =1.3~1.4t (first stretch), 1.15~1.2t (second times stretch), and 1.1t (last stretch). The tensile properties of aluminum sheets are inferior to those of low carbon steel, and they are easily broken when stretched. The tensile height 45mm depends on the diameter of the drawing piece. A cylindrical part of a large cross-sectional area from a material to a small cross section is called a tensile coefficient. That is, the ratio of the cross-sectional area to the cross-sectional area before stretching, i.e., m=A0/An-1. For cylindrical parts, m1=d1/D0, the coefficient of the first stretch can be around 0.5, i.e., the diameter after the first stretch is 1/2 of the blank diameter before the drawing. In the future, the tensile coefficients are usually around 0.7~0.8. The calculation of drawing blank, roughly calculate the blank size according to the principle of equal area of the blank before and after the drawing.

- Q: This question asks for a method to determine the quantity of aluminum sheets required for a specific project.

- <p>To calculate the amount of aluminum sheets needed for a project, first determine the area that needs to be covered. Measure the length and width of the surface in question. Multiply these two dimensions to get the total area in square units (e.g., square feet or square meters). Next, consider the thickness and specific requirements of the aluminum sheets, as this may affect the number of sheets needed. Finally, divide the total area by the coverage area of one aluminum sheet (which can be found from the supplier or calculated if you know the dimensions and thickness of a single sheet). Round up to the nearest whole number to ensure you have enough material for your project. Always account for waste and additional material for cuts or adjustments.</p>

- Q: Is it possible to utilize aluminum sheets in the construction of furniture?

- <p>Yes, aluminum sheets can be used for furniture. They are lightweight, durable, and resistant to corrosion, making them suitable for various types of furniture such as outdoor furniture, tables, chairs, and shelving. Aluminum's strength and flexibility allow for creative designs and easy maintenance. Additionally, it is a sustainable material that can be recycled, contributing to environmental sustainability.</p>

- Q: This question asks about the influence of aluminum sheets on the thermal insulation properties of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can actually reduce the insulation of a building if not properly used. They can conduct heat quickly, which means that they may transfer heat from the outside to the inside or vice versa, depending on the temperature difference. This can lead to increased energy consumption for heating or cooling. However, when used as a reflective barrier in combination with proper insulation materials, aluminum sheets can help reflect heat and improve insulation by reducing heat transfer. It's crucial to use aluminum sheets correctly and in conjunction with other insulating materials to achieve optimal thermal performance in buildings.</p>

- Q: How does 1200X1200X15 6061 aluminum, CNC processing, the plane degree can reach the number of my clients to 0.2, but I used to use the MS 1000X1500X70 to the material processing, the flatness is only 1, please experienced friend to help, thank you

- The first rough machining, no precision position of the first place, finishing allowance for heat treatment of unilateral 0.15MM, and then remove the stress of 420 degrees Celsius for 4 hours, with the furnace cooling (very important), doing fine processing, can guarantee within 0.03

- Q: What are the different methods for punching aluminum sheets?

- There exist numerous techniques for punching aluminum sheets, each possessing its own advantages and applications. Among the different methods are: 1. Manual Punching: This approach entails using handheld tools like handheld punches or hole punches to manually create holes or shapes in the aluminum sheet. It is appropriate for small-scale or low-volume production and provides flexibility in terms of hole size and shape. 2. Mechanical Punching: Mechanical punching involves the utilization of a mechanical press machine equipped with a punch and die set. The sheet is inserted into the machine, and the punch is driven through the material, forming holes or shapes. This technique is quicker and more efficient than manual punching and is fit for medium to high-volume production. 3. CNC Punching: Computer Numerical Control (CNC) punching involves the utilization of automated machinery programmed to punch holes or shapes based on a digital design. The aluminum sheet is loaded onto the machine, and the CNC controls the movement of the punch and die to create precise and intricate patterns. CNC punching offers high accuracy, repeatability, and speed, making it ideal for high-volume production and intricate designs. 4. Laser Punching: Laser punching combines the use of a laser cutter and a mechanical punch to produce holes or shapes in aluminum sheets. The laser beam vaporizes or melts the material, while the punch ejects the cut part from the sheet. This method offers high precision, versatility, and the ability to swiftly cut complex shapes. However, it is typically more expensive and time-consuming compared to other methods. 5. Notching: Notching is a technique employed to create V-shaped or U-shaped cuts in aluminum sheets. It is often used for joining or folding the material to form corners or edges. Notching can be done manually or with the assistance of a mechanical notching machine. The selection of a punching method relies on various factors such as the desired hole size and shape, production volume, precision requirements, complexity of design, and budget. It is crucial to consider these factors and consult with experts to determine the most suitable method for punching aluminum sheets based on specific needs and applications.

- Q: Characteristics of anodized aluminium plate

- (3) strong sense: the metal surface of aluminum anodic treatment of high hardness, as gem, scratch resistance, surface is not covered with paint, keep aluminum metal color, highlight the modern sense of metal, improve product quality and added value.(4) high fire resistance: pure metal products, the surface without paint and any chemical substances, 600 degrees high temperature does not burn, does not produce toxic gases, fire protection and environmental protection requirements.

- Q: what kind of aluminum sheet is suitable for aluminum alloy double-edged saw?

- saw web size depends on the thickness and height of sectional material,equipment compatibility and permitted installed saw web size .

Send your message to us

Aluminum Sheet Price Factory and Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords