Aluminum Decorative Sheets - Anodized Aluminum Sheet Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Anodize Aluminum Sheet Best Quality in China

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Anodize Aluminum Sheet Best Quality in China

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Anodize Aluminum Sheet Best Quality in China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

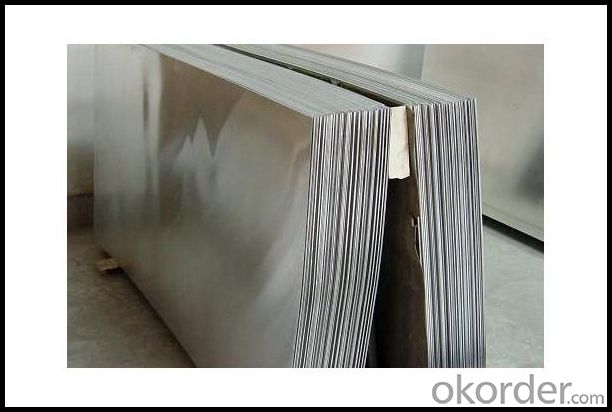

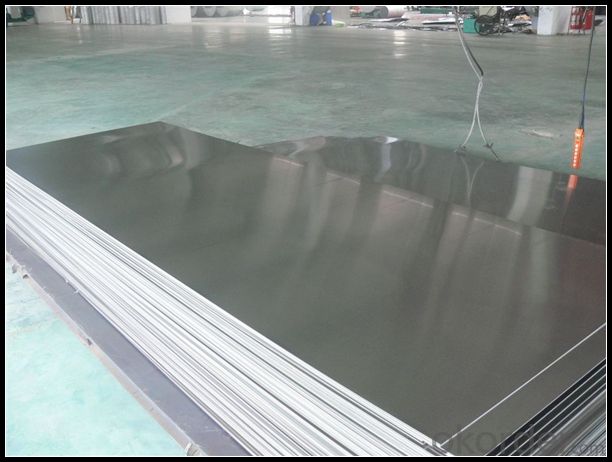

5. Image of Anodize Aluminum Sheet Best Quality in China

6. Package and shipping of Anodize Aluminum Sheet Best Quality in China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for a list of various coatings that can be applied to aluminum sheets for different purposes.

- <p>Aluminum sheets can be coated with a variety of materials to enhance their properties such as durability, appearance, and corrosion resistance. Some common types of coatings include: 1. Anodizing: Creates a protective oxide layer on the aluminum surface. 2. Powder Coating: A dry coating that is electrostatically applied and then cured at high temperatures. 3. PVDF (Polyvinylidene Fluoride) Coating: Known for its excellent resistance to UV, chemicals, and weathering. 4. Epoxy Coating: Provides a hard, durable finish that is resistant to chemicals and corrosion. 5. Polyester Coating: Offers good adhesion and is often used for outdoor applications. 6. Fluorocarbon Coating: Provides a high level of durability and resistance to weathering. 7. Ceramic Coating: A newer type of coating that offers excellent heat resistance and a smooth finish. These coatings are chosen based on the specific requirements of the application, such as architectural, automotive, or aerospace uses.</p>

- Q: Is aluminum a metal or a non-metal?

- Aluminum is a metal. It is a chemical element with the symbol Al and atomic number 13. It is classified as a metal due to its physical and chemical properties. Aluminum exhibits metallic luster, conducts heat and electricity, and has high tensile strength. It is also malleable and ductile, meaning it can be easily shaped into different forms. Additionally, aluminum is typically found in the solid state at room temperature, which is a characteristic of metals. Therefore, based on its properties and classification in the periodic table, aluminum is considered a metal.

- Q: What kind of material is 2A12 aluminum sheet?

- Corrosion resistance is poor, but it can be effectively protected by pure aluminum coating. It is easy to crack when welding, but it can be welded or riveted by special process. Widely used in aircraft structures, rivets, truck hubs, propeller components, and many other structures.

- Q: What are the standards and certifications available for aluminum sheets?

- Aluminum sheets can be evaluated for quality and compliance with industry requirements through various standards and certifications. Some well-known ones include: 1. ASTM International Standards: Developed by the American Society for Testing and Materials (ASTM), these standards focus on aspects like chemical composition, mechanical properties, and dimensional tolerances. They promote consistent quality across different aluminum sheet products. 2. ISO 9001: This globally recognized certification establishes guidelines for quality management systems. Aluminum sheet manufacturers with ISO 9001 certification demonstrate their commitment to meeting customer requirements, continuous improvement, and strict quality control processes. 3. ASME Standards: The American Society of Mechanical Engineers (ASME) has specific standards for aluminum sheet materials used in pressure vessels, piping, and other applications. These standards ensure the safety and reliability of aluminum sheets in critical applications. 4. MIL-Specifications: The United States Department of Defense (DoD) has developed military specifications (MIL-Specs) for materials, including aluminum sheets. These specifications define the requirements for military-grade aluminum sheets, ensuring their suitability for defense applications. 5. EN Standards: The European Committee for Standardization (CEN) has established a series of European Norm (EN) standards for aluminum and aluminum alloys. These standards cover chemical composition, mechanical properties, and surface finishes, ensuring compatibility and consistency in the European market. 6. RoHS Compliance: Compliance with the Restriction of Hazardous Substances (RoHS) is crucial for aluminum sheets used in electrical and electronic equipment. This certification guarantees that the aluminum sheets are free from hazardous substances, ensuring environmental safety. Manufacturers and suppliers of aluminum sheets must adhere to these standards and certifications to ensure their products are of the highest quality, safety, and suitability for specific applications.

- Q: What are the properties of anodized aluminum sheets?

- Anodized aluminum sheets are highly desirable for a variety of applications due to their distinct properties. Firstly, they possess a protective oxide layer on their surface, which enhances their resistance to corrosion. This layer is formed through an electrochemical process called anodization, wherein the aluminum sheet is treated with an electric current in an acid electrolyte solution. Consequently, anodized aluminum sheets become more durable and capable of withstanding harsh environments, making them suitable for outdoor use. Another notable property of anodized aluminum sheets is their improved scratch resistance. Through the anodization process, not only is a protective layer created, but the surface of the aluminum also becomes hardened, rendering it more resistant to scratches and wear. This property proves particularly advantageous in applications where frequent handling or abrasive conditions are involved. Moreover, anodized aluminum sheets can be manufactured in a wide range of colors. The anodization process enables the integration of dyes or pigments into the oxide layer, resulting in an array of vibrant color options. This aspect makes anodized aluminum sheets highly popular in architectural and decorative applications, as they can be customized to meet specific design requirements. Additionally, anodized aluminum sheets possess excellent thermal and electrical conductivity. The process of anodization does not significantly impact these inherent properties of aluminum. Consequently, anodized aluminum sheets can efficiently dissipate heat and conduct electricity, making them well-suited for applications such as heat sinks, electronic enclosures, and electrical components. To sum up, anodized aluminum sheets possess enhanced corrosion resistance, improved scratch resistance, a wide range of color options, and excellent thermal and electrical conductivity. These properties render anodized aluminum sheets a versatile and durable material for various industries and applications.

- Q: Aluminum or steel bike frame cost more???...which one cost the most usually???

- Good quality steel frames are almost always more expensive than aluminum. There are a couple of reasons for this... 1) Aluminum is always welded. This takes much less effort and time than a fine brazed steel unit; 2) High quality steel tubing is very expensive compared to aluminum due to the thin walls and sometimes exotic alloying materials; 3) Aluminum is one of the most common elements on the planet. Common steel alloys have harder-to-obtain elements such as molybdneum, manganese, and other rare metals. 4) Although many aluminums require post weld processing it takes little or no labor to complete it while a high quality steel frame responds beautifully to hand work. 5) A good steel frame is simply harder to find nowadays. I know that this goes beyond the scope of your question, but keep in mind that regardless of the aluminum alloy it all weighs the same; regardless of the steel alloy it all weighs the same. The difference in weight comes from modifying the metal mixture, enabling a stronger metal and making of ever-thinner tubes. Kojman47 (below) is WAAY off in his interpretation of materials. There are steel frames that rival the weight and strength of titanium which is often 1/2 the weight of aluminum. There is no such thing as cromolly. The correct name (if I may) is Chrome Molybdneum, abbreviated as CrMo, often called Chrome Moly. Cromoly or cromolly or cromo doesn't give proper respect to the alloy OR to the frame. CrMo (cromolly in Kojmans eyes) is steel.

- Q: Is it possible to use aluminum sheets as an insulating material for walls in new construction projects?

- <p>Aluminum sheets themselves are not typically used for wall insulation due to their poor insulating properties. Aluminum is a good conductor of heat, which makes it unsuitable for insulation as it can transfer heat easily, leading to energy loss. However, aluminum can be used as a vapor barrier or as part of a composite material in combination with proper insulation. For effective insulation, materials with low thermal conductivity like fiberglass, cellulose, or foam are commonly used.</p>

- Q: combines with oxygen with an atomic weight of 16, to form the compound aluminum oxide, how much oxygen would be required to react completely with 54g of aluminum?

- Well, Al2O3 is the formula for aluminum oxide So you have 2 moles of Al, so you need 3 moles of O which is 1.5 moles of O2 So the answer is 48g

- Q: This question asks for signs or indicators that would suggest whether a roof needs to be replaced or repaired using aluminum sheets.

- <p>To determine if your roof needs replacement or repair with aluminum sheets, look for the following signs: visible rust or corrosion, especially on the seams and fasteners; sagging or buckling in the roof surface; leaks or water damage inside your home; and excessive noise during rain or wind. If the damage is widespread or the roof is old, replacement might be necessary. However, if the damage is limited to specific areas, repairs could suffice. It's always best to consult with a professional roofer for an accurate assessment.</p>

- Q: How do aluminum sheets perform in terms of machinability?

- Aluminum sheets are known for their excellent machinability. They can be easily cut, drilled, and shaped using various machining processes such as milling, turning, and drilling. Aluminum has a low melting point and is relatively soft, making it easier to work with compared to other materials like steel. Additionally, aluminum sheets have good chip control, which means they produce smaller and more manageable chips during machining. This reduces the risk of tool breakage and improves the overall efficiency of the machining process. Furthermore, aluminum sheets have good thermal conductivity, which helps dissipate heat generated during machining, preventing tool wear and prolonging tool life. Overall, aluminum sheets are highly machinable and widely used in various industries for their ease of machining and versatility.

Send your message to us

Aluminum Decorative Sheets - Anodized Aluminum Sheet Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords