Black Annealed Wire Binding Wire Soft Wire Real Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Black Annealed Wire Binding Wire Soft Wire Real Factory Description:

Black Annealed Iron Wire is mainly processed into coil wire, spool wire or big package wire. Annealed wire is used as tie wire or baling wire in building, parks and daily binding. Besides, black annealed wire is mainly used as industrial wire, construction wire, industrial bale tie wire and constructional tie wire, etc.

Black Annealed Iron Wire is extensively used in construction, handicrafts, woven wire mesh, express way fencing mesh, packaging of products,etc.Black annealed wire is mainly used in buiding and construction as binding wire, tie wire and baling wire.Black annealed wire is widely used as tie wire or baling wire in building, parks and daily binding.In agriculture annealed wire is used for bailing hay.Meantime black annealed wire can processed into coil wire, spool wire, big package wire orfurther traightened and cut into cut wire or U type wire.

2.Main Features of Black Annealed Wire Binding Wire Soft Wire Real Factory:

soft tenacity, strong tensile strength, corrosion resistance, folding resistance is strong, colour and lustre is uniform

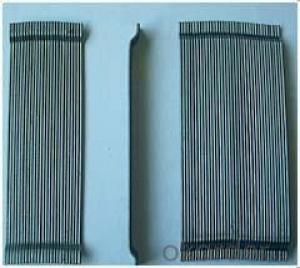

3. Black Annealed Wire Binding Wire Soft Wire Real Factory Images

4.Black Annealed Wire Binding Wire Soft Wire Real Factory Specification

Gage No. | BWG(mm) |

Metric(mm)

|

8 | 4.191 | 4.00 |

9 | 3.759 | 4.00 |

10 | 3.404 | 3.50 |

11 | 3.048 | 3.00 |

12 | 2.769 | 2.80 |

13 | 2.413 | 2.50 |

14 | 2.108 | 2.50 |

15 | 1.829 | 1.80 |

16 | 1.651 | 1.65 |

17 | 1.473 | 1.40 |

18 | 1.245 | 1.20 |

19 | 1.067 | 1.00 |

20 | 0.8886 | 0.90 |

21 | 0.8128 | 0.80 |

22 | 0.7109 | 0.70 |

5.FAQ

①Are you a factory?

Yes, We are a professional manufacturer of wire in China. The Mainly product is electro galvanized iron wire, black annealed iron wire, wire nail. Our company is built by two boss, one own a black annealed wire factory,the other own a galvanized wire factory.

②Is your company offer the sample?

Of course, our factory could supply the sample for free. Also we could OEM the quality as your requirement

③What does the process of your wire?

the Q195 wire rod drawing model into the black iron wire, through 1000° high temperature firing, black iron wire after annealing treatment, soft wire, can increase the wire tensile degrees.

- Q: for standard electric wiring, do I cut the white wire or the black wire to not get shocked?

- don't touch a thing you fool!!!!!!!!!!!!!!!!1 the electricity doesn't know what color the wire is if the last guy did it wrong either wire could kill you you COULD HAVE REVERSE POLARITY SWITCHED NEUTRALS, SWITCH LOOPS THERE ARE ENDLESS WAY TO WIRE THAT COULD MAKE THE WHITE , BLACK OR BOTH DANGEROUS if the last guy did it right either wire could kill you

- Q: What is the use of Fence baebed wire?

- to keep people in or out of certain places.

- Q: I have a phone line with 8 wires that is wired to the house, how do you select which wire to use on a 4 wire phone line?

- How To Wire Phone Line

- Q: I recently Hooked a newer Pioneer cd player up in my 00 mustang gt!.. it will not keep memory. The only way it will come on is when the red(power) is hooked up with the Yellow wire!.. but this way it will not hold a memory.. theres a few orange wires but i have hooked them up and it still wont keep memory? any suggestions?

- I am installing a Pioneer Car Stereo and not sure if the yellow or blue wire are the memory wire

- Q: the charger has three wires to put a male plug on and they are black white and green and they look like 12 gauge wires

- wire colors are green is ground the black and white wires are you load wires look at you 240 volt plug and determine which terminal is the ground this one is where the green wire goes the black and white wire go to other two terminals this should do it

- Q: I wanted to ask, im busy installing a new stereo headset for my car,when i replaced the old stereo with the new one, i used the wire harness from the old stereo and joint the wires to the back of new the stereo (which there is another black adapter that goes in the wire harness area on the the new stereo) i did this by connecting the wires from the stereo adapter to the wire harness that connects to the car, although the adapter that connects to the stereo has more wires than the wire harness that connects to the car,( i only connected the wires that were matching such as grey wire to grey wire, grey wire with black strip to grey wire with black strip, and so on, i obviously didn't connect the colours that didn't match to the wire harness wires, although i looked up online and apparently the yellow wire is a power wire, but i don't know where to connect it......if anyone could help, this would be greatly appreciated , i also wanted to ask, would this solve the problem if i buy a new wire harness? Thanks

- What kind of car is it? That's important, especially if it's a foreign make because those wires are so weird colored. Typically, yellow or ornage is power, red is memory, and the purple, gray, white, green wires are for the speakers .Black or brown wires are ground. Any blue wires you might come across are mainly just auxiliary signal wires that go to an aftermarket amp and subwoofer setup. Unless you have something like that, those wires can be taped off and forgotten about. Also, when wiring an aftermarket radio to your car, you will need to purchase an adapter harness that plugs into the stock wiring of the car and the wires connect to the radio wire harness correspondingly. I suggest soldering all the necessary wires and sealing them with shrink tube. It's the most solid, most sure way of a good connection without the worry of shorts and disconnections.

- Q: electrical wire prices

- Doh!! The reason the prices of wire follow the prices of oil, the outer jacket of Wire is Plastic an oil based product, Thus the reason oil goes up so does the prices of wire.

- Q: The wire on my headphones were cut clean off in the middle of the wire. Is there any way it can be fixed? I tried to find out other ways but it seems one of the only ways is to strip the wire of its covering. Is there a way to fix it without burning the wires?

- to add to Generic John's post ..pay attention to the color of the wires. one will most likely have no cover to it ,thats the neutral. so it would be for example . to red,white to white , neutral to neutral

- Q: so im doing a custom buggy and i need so different colored wire im looking for a place to get lots of different colored wire for cheap

- id try a hardware store or radio shack.

- Q: I have an old sewing machine without a plug that needs wiring up but it doesn't have the modern wire colours. There's one red wire and one yellow. Does anyone know how to do this?Thanks =]

- It would be better for you to post a picture of your wires and where they are going to on the machine so that we can tell you what is what. Otherwise it would be difficult to say just by telling us one is red and one is yellow. No offense intended, there's just not enough information with just knowing the wire colors. ------------------------ WARNING! Red is NEVER used to indicate a earth connection as XOXO suggests! Damage to your machine or harm to you could result if you attempted to connect red to earth. ------------------------ OK, I see your picture (thanks): Yellow is most likely the common wire. It connects to your white wire. The red wire connects to the Hot (black) wire. If you have a switch in the system, the red wire would connect to your switch or foot (gas peddle). And of course the other side of your switch would be connected to your black wire of the power cord.

Send your message to us

Black Annealed Wire Binding Wire Soft Wire Real Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords