Soft Black Annealed Iron Wire Black Annealed Wire Low Price Black Annealed Wire

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Soft Black Annealed Iron Wire Black Annealed Wire Low Price Black Annealed Wire Description:

Black Annealed Iron Wire also called galvanized steel wire, galvanized iron wire according to the difference zinc coating process, there are electro galvanized iron wire and hot-dipped galvanized iron wire.

Black Annealed Iron Wire can be classified into hot-dipped galvanized iron wire and electro galvanized wire according to the differences of processing. This wire is very good for Chain link fence, fencing mesh, gabion mesh box production and for construction business as tire wire, binding wire and galvanized wire raw material production.

2.Main Features of Black Annealed Iron Wire:

• Use widely

• Corrosion- resistant

• Durable

• Practical use

• Beauty Surface

3.Black Annealed Iron Wire Images

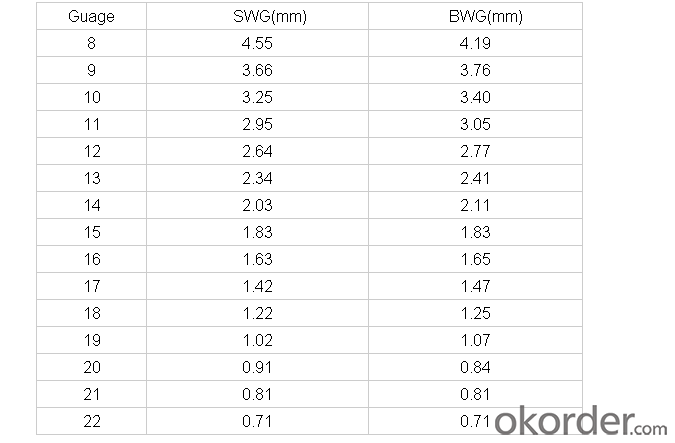

4.Black Annealed Iron Wire Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

We are focus on steel wire trading for more than ten years. We are specialized in export of various kinds of steel wire and wire mesh products, like Black Annealed Iron Wire we offer high quality steel wire; hot dipped wire; electro galvanized wire; PVC /PE coated wire; fencing , steel wire rope, steel wire strand, cable wire; wire mesh and other wire related products.

②What is the advantage of our Black Annealed Iron Wire?

1. Durable service life and competitive price.

2. Beautiful, strong and not expensive.

3. With long live and good anti-corrosive

4. High quality and low price.

③How long can we receive the product after purchase?

In the purchase of Black Annealed Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: I'm cutting 18 gauge wire, so I can run valve wires to the timer in the garage. The plastic casing over the wire is pretty thick, so I had to squeeze hard. I accidentally cut into the color casing of the actual wire inside, so I want to start over. How can I cut this wire away, and start again?

- Use a utility knife and cut around the casing then strip it off. Or run out to Home Depot and get yourself a wire cutter stripper tool.

- Q: I keep thinking that the wire would cut into the bark when the bonsai is growing.I want to wire it now because it is easily manipulative, but I don't want to prevent trunk growth

- Wire it, let it grow a bit. Then, as necessary, undo the wire, then rewire it to fit the new size. An alternative is to append weights, or tie strings to other objects or parts of the plant instead of wiring a whole branch.

- Q: Does anyone know what the wire harness is called that runs from the chassis to the door called on a 1995 jeep gc. This wire harness includes the speaker wires, power window wires, and power lock wires. I have checked everywhere and cannot see what this harness is called.

- Its called a wire harness. I beleive it is the main dash wire harness, but you wont get anywhere with that if you are trying to get one from a parts house or dealer, You just have to hit and miss at the salvage yard or digging around yourself and get lucky. But if you can trace the wires to a block connector or firewall connector you will be in luck and just tell them the location of the block where the harness is connected and you should be there, just remember all your options in you truck will have to match the options in the donor truck or the harness wont work for you

- Q: ok so i have 3 questions.i have an oldsmobile cuttlas supreme and i have a 0 gauge power wire that is 17 feet is that long enough???? and i have 0 gauge ground that is 17 feet is that long enough....and about the speaker wire..i have 8 gauge speaker wire that is 25 feet..is this a good setup.make sure u answer all these questions please thank you..

- the 17 ft of power wire is going to be fine. Just make sure you install an inline fuse by the battery. The 17ft of ground wire is a little bit too much, but you can cut that down. Make sure you ground the amp as close as possible so the voltage drop is minimal. The 8 guage speaker wire is way too high a gauge for speaker wire. You would be fine with 12, 14, or 16 gauge. The length needed depends on what speakers you plan to wire up. If its just subs then I would say thats more than enough. If you're powering components, you will need much more, probable close to 100. Overall it should be a good setup though.

- Q: A potential difference of 13 V is found to produce a current of 0.37 A in a 3.1 m length of wire with a uniform radius of 0.42 cm.(a) What is the resistance of the wire? (b) What is the resistivity of the wire? Please show work.

- Voltage (Volts) = Current (Amps) times Resistance (Ohms) or V=IxR = R = V/I = 13/0.37 = 35.14 Ohms Resistance = Resistivity * Length/Area The longer the wire is, the more resistance it has. The larger the crossectional area of the wire (pi times radius^2), the less resistance it has Longer wires have more resistance, thicker wires have less 35.14 = Resistivity * 3.1/pi*0.0042^2 Resistivity = 35.14*pi*0.0042^2/3.1 = 6.281 x 10^-4

- Q: i need 175ft of 110 wire how much does it cost?

- Most all of the wire used in an average home will carry 110 volts. If you're looking to install some new recepts or switches, then most likely #12 wire would work just fine. At 175', you're going to use most of a 250' roll, which is the way most residential wire is sold. A 250' roll will run about $35 - $40 depending on where you live and whether you buy it at a wholesale electrical supply house or a retail store. Buying the wire by the foot will most likely cost about the same as the price/ft. for cut wire goes up.

- Q: Why when you loop a straight wire into loops (coil), it acquires a higher inductance?

- If the ends of the wire are joined to form a circuit each loop forms a path for induced current, the currents of each loop are accumulative.

- Q: Whenever I'm making jewelry, I typically wind up using crimp beads (with toggle closures, in most cases). Whenever I cut off the beading wire at the end, after enclosing the crimp bead around it, there's always this itsy bitsy part of the wire that irritates me to no end when I wear the jewelry. It seems that I can only cut the wire so much before I wind up snipping at the crimp bead. How can I remedy the irritation fact of the left-over wire?Maybe put glue on the wire piece and let it dry? Idk. Grr.

- Here is the way to get rid of the scratchy wire: Take the wire on through the crimp bead and thread it down into the beads, and then crimp the wire. If you have a little wire sticking out there on down between the beads, just bend back the beads, and clip it with your jewelry wire cutters that have a side edge. Be sure and cut your wire with a couple inches to spare so you have enough wire to attach the clasp and thread the wire down. I was having trouble with the crimp bead scratching, no matter how I crimped it. I found out that they sell a crimp cover. It looks like an open clam shell, and you just slip it over the crimp bead, and close it with pliers. Beware, there is something called a clam shell, but it has a eye on it, it is for non-metal stringing materials. Another thing I found was a little tiny horseshoe called a guide. It goes above the crimp bead, and holds the clasp. It protects the wire from the wear and tear of the clasp. And it is so easy to pull the wire through it once it is on, you can adjust the length of the wire over and over. I was literally stuffing the wire down into the beads with a pliers. No more! Just pull on the end, and down the wire goes. No more ugly lengths of wire between the beads and the crimp bead. I found both these items in gold and silver colors, at Michaels, and Craft etc on line, and on other online sites. So, save the glue for working with elastic cord and gluing a bead over the knot to hide it.

- Q: Hi, I'm extending my pc 5.1 sound system stereo cables. I have a M/F extension wire which I will cut to solder a seamless wire to the system. Problem is that in the system cable I have a white, green(or red) and bare wire. and ont he extension I have a black red and white. Which wire do I connect to which?thanks

- I'n not sure I understand the problem. In my view if you have 3 wires -- ending in, let's say, three plugs -- and want an extension it doesn't matter what colour the wires are as long as you end up connecting the original wires to the same plugs. So if you have white, green and bare on the original cable, when you cut the cable you have white, green and bare on both halves. Use the white, black, red extension cable to connect the two halves. I'd suggest white white, green red, and bare to black at one end and the same at the other ... but it doesn't really matter. Hope that helps.

- Q: like can u use home power wire that is 4 gauge rather then getting the car power wire

- Home okorder /... (spanky, well trying to run solid wire in a car would be a real task! lol) And, 4 gauge can handle more than 95 amps.

Send your message to us

Soft Black Annealed Iron Wire Black Annealed Wire Low Price Black Annealed Wire

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords