Billet Bicycle Wheel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Billet Bicycle Wheel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

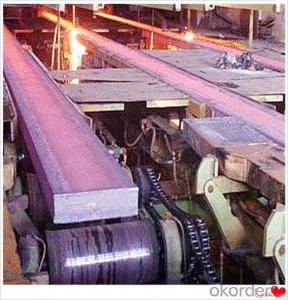

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: Are steel billets used in the manufacturing of construction machinery?

- Yes, steel billets are commonly used in the manufacturing of construction machinery. Steel billets are semi-finished products that are used as raw materials in various industries, including construction machinery manufacturing. These billets are typically made from molten steel that is cast into a solid form and then further processed to shape and size. Due to their high strength, durability, and versatility, steel billets are ideal for constructing heavy-duty components and structures in construction machinery. They can be used to manufacture various parts such as chassis, frames, buckets, booms, and arms, among others. The use of steel billets ensures that construction machinery is capable of withstanding the demanding conditions and heavy loads commonly encountered in construction projects.

- Q: What are the different types of cutting processes used for shaping steel billets?

- Steel billets can be shaped using various cutting processes. Some of these methods include: 1. Bandsaw cutting, a popular technique that employs a continuous band of toothed metal blade to cut through the billet. Bandsaws are highly regarded for their quick and accurate cutting of thick steel sections. 2. Abrasive cutting, which involves using an abrasive wheel or disc to slice through the billet. This method is versatile, being suitable for smaller billets and for creating intricate shapes and contours. It is known for its ability to produce precise and smooth cuts. 3. Plasma cutting, a thermal cutting process that employs a high-velocity jet of ionized gas to melt and eliminate the steel from the billet. This technique is often employed for thick steel sections and intricate shapes. It boasts high speed and the ability to produce clean cuts. 4. Waterjet cutting, a process that employs a high-pressure jet of water to cut through the steel billet. In some cases, abrasive particles may be introduced to enhance the cutting ability. Waterjet cutting is renowned for its capability to cut through thick steel sections without causing heat-affected zones or distortion. 5. Laser cutting, which utilizes a high-powered laser beam guided by computer controls to melt and vaporize the steel billet. This method is known for its precision and the ability to cut intricate shapes with minimal distortion. These examples represent only a few of the cutting processes available for shaping steel billets. Each technique has its own set of advantages and is selected based on factors such as billet size, desired shape, and required accuracy.

- Q: What are the applications of steel billets in the automotive industry?

- Steel billets are an essential component in the automotive industry, playing a crucial role in various applications. One of the primary uses of steel billets in this industry is for the production of engine parts. The billets are forged and machined to create crankshafts, connecting rods, and camshafts, which are vital components for the proper functioning of an engine. Steel billets are also used in the manufacturing of suspension and steering components. These billets are shaped into various parts such as control arms, tie rods, and steering knuckles, which provide stability, control, and smooth handling to the vehicle. These components are crucial for ensuring a safe and comfortable driving experience. Furthermore, steel billets find applications in the production of transmission components. They are forged and machined to create gears, shafts, and other transmission parts that facilitate the smooth transfer of power from the engine to the wheels. These components play a significant role in the overall performance and efficiency of the vehicle. Additionally, steel billets are used in the manufacturing of chassis and frame components. By using billets, manufacturers can create strong and durable structures that provide stability and support to the entire vehicle. Chassis components such as cross members, brackets, and reinforcements are often made from steel billets to ensure the vehicle's structural integrity. In summary, steel billets are widely employed in the automotive industry for various applications. They are used to create engine parts, suspension and steering components, transmission parts, and chassis components. The use of steel billets in these applications ensures the durability, performance, and safety of vehicles.

- Q: How are steel billets used in the manufacturing of construction materials?

- The manufacturing of construction materials relies heavily on steel billets, which are a necessary raw material. These semi-finished forms of steel serve as the initial stage for various construction products, including rebars, beams, columns, and plates. During the production process, steel billets undergo heating and are then passed through a series of rolling mills to achieve the desired shape. For example, when producing rebars, the billet is heated and rolled into long, slim bars of different diameters. These rebars are commonly used in construction to reinforce concrete structures, ensuring their durability and strength. Likewise, steel billets are utilized in the creation of beams, columns, and plates, which are essential elements in building construction. Beams provide structural support, while columns bear the weight of the structure and transmit loads to the foundation. Plates, on the other hand, find applications in flooring, walls, and roofing. The utilization of steel billets in construction materials offers numerous benefits. Steel, renowned for its high strength-to-weight ratio, provides exceptional structural integrity, resulting in more efficient and cost-effective construction. Furthermore, steel is highly ductile, allowing it to be easily shaped and molded into various forms, enabling versatility in design and construction. Additionally, steel is a durable material that exhibits excellent resistance to environmental factors like corrosion and fire. Consequently, steel construction materials have a long lifespan and are suitable for a wide range of applications, including high-rise buildings, bridges, and infrastructure projects. In conclusion, steel billets play a vital role in the manufacturing of construction materials. By being transformed into rebars, beams, columns, and plates, these billets provide the necessary strength, durability, and versatility required in the construction industry.

- Q: What is the role of steel billets in the manufacturing of automotive engine components?

- Steel billets are a crucial raw material in the manufacturing of automotive engine components. These billets serve as the starting point for the production process, as they are heated and shaped into various forms such as rods, bars, or sheets. These components, made from steel billets, provide the strength, durability, and heat resistance required for engine parts such as crankshafts, connecting rods, and cylinder heads. In essence, steel billets are the foundation for creating high-quality and reliable engine components that ensure optimal performance and longevity in vehicles.

- Q: What are the specifications for tool steel billets used in the manufacturing of cutting tools?

- The specifications of tool steel billets used in the manufacturing of cutting tools can vary depending on the specific application and requirements. However, there are some commonly followed general specifications. 1. Composition: High-carbon alloy steels are typically used to make tool steel billets. These steels contain elements such as chromium, molybdenum, vanadium, tungsten, and cobalt, which enhance the hardness, wear resistance, toughness, and heat resistance of the tool steel. 2. Hardness: Tool steel billets need to have high hardness in order to withstand demanding cutting conditions. The hardness is usually measured on the Rockwell C (HRC) scale and can range from 58 HRC to 65 HRC or even higher for certain applications. 3. Wear Resistance: Cutting tools experience abrasive wear during operation. Therefore, tool steel billets are formulated to have excellent wear resistance properties, ensuring a longer tool life. This is achieved by incorporating alloying elements like chromium and vanadium, which increase the hardness and wear resistance of the tool steel. 4. Toughness: In addition to hardness and wear resistance, tool steel billets must have sufficient toughness to endure the high impact forces generated during cutting. High toughness ensures that the cutting tools do not easily fracture or chip, even under severe cutting conditions. 5. Heat Resistance: Cutting tools often face high temperatures during operation, especially in high-speed cutting applications. Tool steel billets must possess good heat resistance to prevent softening or deformation at elevated temperatures. This is achieved by adding alloying elements like molybdenum and tungsten, which contribute to the heat resistance properties of the tool steel. 6. Machinability: Tool steel billets should have good machinability to enable the production of complex cutting tool geometries with high precision. The proper selection of alloying elements and heat treatment processes can enhance the machinability of tool steel billets. It is important to note that the specific specifications for tool steel billets may vary depending on the cutting tool application, the material being cut, and the machining conditions. Therefore, consulting with the tool steel manufacturer or supplier is crucial to determine the exact specifications required for a particular cutting tool application.

- Q: What are the different types of cutting methods used for steel billets?

- There are several different types of cutting methods used for steel billets, including sawing, shearing, flame cutting, and water jet cutting.

- Q: How are steel billets used in the manufacturing of electrical transmission equipment?

- Steel billets serve as a key raw material in the manufacturing of electrical transmission equipment. They are solid blocks of steel that undergo further processing to create various components necessary for electrical transmission equipment. One crucial application of steel billets in this field is for the production of transmission towers. These towers are essential infrastructure that supports power lines and facilitates the secure and efficient transmission of electricity over long distances. Steel billets are utilized in the manufacturing of the structural elements of these towers, including the main vertical and horizontal members, as well as the cross arms and braces. Moreover, steel billets are also employed in the production of conductors for electrical transmission equipment. Conductors are the cables responsible for carrying electrical current between power generation stations and distribution networks. Steel billets are processed to create the wires and strands required to construct these conductors. The remarkable strength and durability of steel make it an excellent material choice for these applications, as it can withstand the high tension and load demands of electrical transmission systems. Furthermore, steel billets are utilized in the manufacturing of various other components used in electrical transmission equipment, such as pole line hardware, insulators, and connectors. These components are essential for the proper functioning and reliability of the electrical transmission system, and steel billets provide the necessary strength and stability required for their construction. To summarize, steel billets play a crucial role in the manufacturing of electrical transmission equipment. They are used to produce transmission towers, conductors, and other vital components, ensuring the safe and efficient transmission of electricity over long distances.

- Q: What are the main factors affecting the weldability of steel billets?

- The weldability of steel billets is influenced by several primary factors. To begin with, the composition of the steel billet plays a crucial role. The presence of specific elements, such as carbon, sulfur, phosphorus, and nitrogen, can have adverse effects on weldability. For instance, higher carbon content can result in the creation of brittle regions within the weld zone. Similarly, sulfur and phosphorus can induce porosity and other defects during welding. Additionally, the heat treatment history of the steel billet is another significant factor. Processes like annealing, quenching, and tempering can modify the steel's microstructure, impacting its mechanical properties and weldability. Excessive hardening, for example, can lead to cracking during the welding process. The presence of impurities and contaminants in the steel billet can also have a negative impact on weldability. These impurities can cause the formation of inclusions and defects within the weld, reducing its strength and integrity. Therefore, it is essential to ensure that the steel billet is thoroughly cleaned and free from contaminants before welding. Furthermore, the size and shape of the steel billet also affect weldability. Thicker billets require higher heat input during welding, resulting in increased residual stresses and distortion. Additionally, complex geometries or irregular shapes can pose challenges in achieving proper joint penetration and fusion during welding. Finally, the welding process itself can influence the weldability of steel billets. Factors such as welding technique, heat input, welding speed, and the use of filler materials all impact the quality of the weld. Selecting the appropriate welding process and parameters is crucial to ensure a sound and defect-free weld. In conclusion, the weldability of steel billets is influenced by factors such as composition, heat treatment history, impurities, size and shape, and the welding process. Carefully considering and managing these factors is essential to achieve high-quality welds and maintain the integrity and performance of steel structures.

- Q: What are the future trends in steel billet production?

- The future trends in steel billet production are focused on improving efficiency, sustainability, and quality. One major trend is the adoption of advanced technologies in the production process. Automation and robotics are being increasingly utilized to streamline operations, reduce human error, and increase productivity. This includes the use of artificial intelligence and machine learning algorithms to optimize the production parameters and improve the overall process control. Another trend is the shift towards greener and more sustainable practices. Steel producers are investing in technologies that reduce carbon emissions, such as the use of electric arc furnaces (EAFs) instead of traditional blast furnaces. EAFs consume less energy and emit fewer greenhouse gases, making them a more environmentally friendly option. Moreover, there is a growing emphasis on recycling and circular economy principles in steel billet production. Companies are investing in scrap metal recycling technologies to reduce the reliance on raw materials and minimize waste. This not only helps conserve resources but also reduces the carbon footprint of steel production. Quality control is also a key focus in future trends. Steel producers are implementing advanced testing and inspection techniques to ensure the highest quality standards. This includes the use of non-destructive testing methods, such as ultrasonic and magnetic particle testing, to detect any defects or flaws in the billets. Overall, the future of steel billet production is driven by technological advancements, sustainability, and a commitment to delivering high-quality products. These trends aim to make the steel production process more efficient, environmentally friendly, and economically viable for the long term.

Send your message to us

Billet Bicycle Wheel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords